Artistic design printing packaging paper mildewproof treatment coating

A technology for printing and packaging and anti-mildew treatment, which is applied to wrapping paper, wrapping paper, coating, etc. It can solve the problems of not having anti-mildew and antibacterial functions, and can not meet the storage requirements of paper, so as to achieve superior flame retardancy and improve product performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

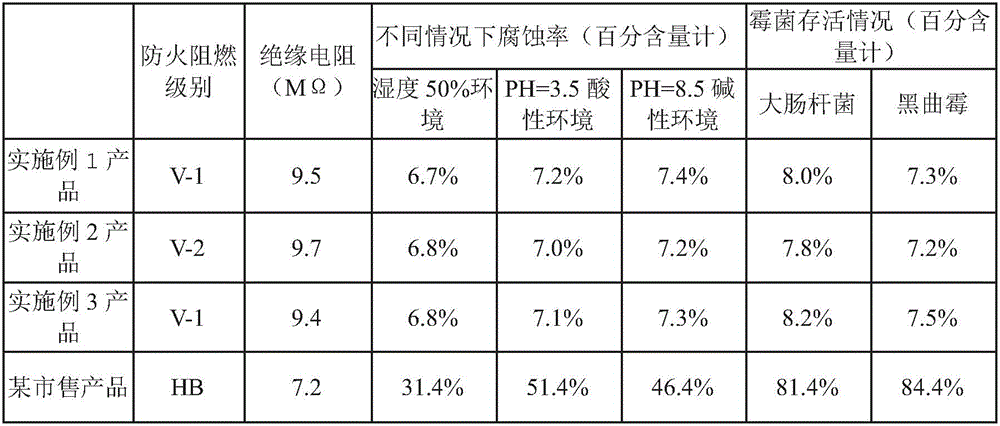

Examples

Embodiment 1

[0016] The anti-mildew treatment coating for artistic design printing wrapping paper in the present embodiment is made up of the following components in mass parts: 28 parts of polyethylene, 26 parts of furfuryl alcohol resin, 26 parts of halogenated butyl rubber, 24 parts of hydrogenated castor oil, pine 26 parts of oleyl alcohol, 26 parts of Nepeta oil, 24 parts of linseed oil, 26 parts of butyl acetate, 26 parts of nano silver, 24 parts of limonene, 24 parts of calcium borate, 24 parts of trichloroisocyanuric acid, 26 parts of active zinc oxide Parts, 24 parts of methyl tert-butyl ether, 22 parts of basic lead silicochromate, 26 parts of sodium pyrophosphate, 24 parts of coke, 22 parts of polypropylene wax, 24 parts of sericite powder, 22 parts of spodumene powder, amidine 22 parts of urea phosphate, 24 parts of trioctyl phosphate, 24 parts of polyacrylonitrile fiber, 24 parts of ammonium dihydrogen phosphate, 24 parts of diglycidyl ether, 24 parts of dibasic lead phthalate,...

Embodiment 2

[0022] The anti-mildew treatment coating of art design printing wrapping paper in the present embodiment is made up of the following components in mass parts: 30 parts of polyethylene, 28 parts of furfuryl alcohol resin, 28 parts of halogenated butyl rubber, 26 parts of hydrogenated castor oil, pine 28 parts of oleyl alcohol, 28 parts of Nepeta oil, 26 parts of linseed oil, 28 parts of butyl acetate, 28 parts of nano silver, 26 parts of limonene, 26 parts of calcium borate, 26 parts of trichloroisocyanuric acid, 28 parts of active zinc oxide Parts, 26 parts of methyl tert-butyl ether, 24 parts of basic lead silicochromate, 28 parts of sodium pyrophosphate, 26 parts of coke, 24 parts of polypropylene wax, 26 parts of sericite powder, 24 parts of spodumene powder, amidine 24 parts of urea phosphate, 26 parts of trioctyl phosphate, 26 parts of polyacrylonitrile fiber, 26 parts of ammonium dihydrogen phosphate, 26 parts of diglycidyl ether, 26 parts of dibasic lead phthalate, 26 pa...

Embodiment 3

[0028] The anti-mildew treatment coating for art design printing wrapping paper in this embodiment consists of the following components in parts by mass: 32 parts of polyethylene, 30 parts of furfuryl alcohol resin, 30 parts of halogenated butyl rubber, 28 parts of hydrogenated castor oil, pine 30 parts of oleyl alcohol, 30 parts of Nepeta oil, 28 parts of linseed oil, 30 parts of butyl acetate, 30 parts of nano silver, 28 parts of limonene, 28 parts of calcium borate, 28 parts of trichloroisocyanuric acid, 30 parts of active zinc oxide Parts, 28 parts of methyl tert-butyl ether, 26 parts of basic lead silicochromate, 30 parts of sodium pyrophosphate, 28 parts of coke, 26 parts of polypropylene wax, 28 parts of sericite powder, 26 parts of spodumene powder, amidine 26 parts of urea phosphate, 28 parts of trioctyl phosphate, 28 parts of polyacrylonitrile fiber, 28 parts of ammonium dihydrogen phosphate, 28 parts of diglycidyl ether, 28 parts of dibasic lead phthalate, 28 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com