Treatment method and device for blocking of air preheater of coal-fired utility boiler

An air preheater, coal-fired power station technology, applied in the combustion method, combustion air/fuel supply, non-flammable liquid/gas transportation, etc. Increase the resistance of the air preheater to reduce the tendency of fouling and scaling, reduce particles with high silicon content, and reduce agglomerated particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

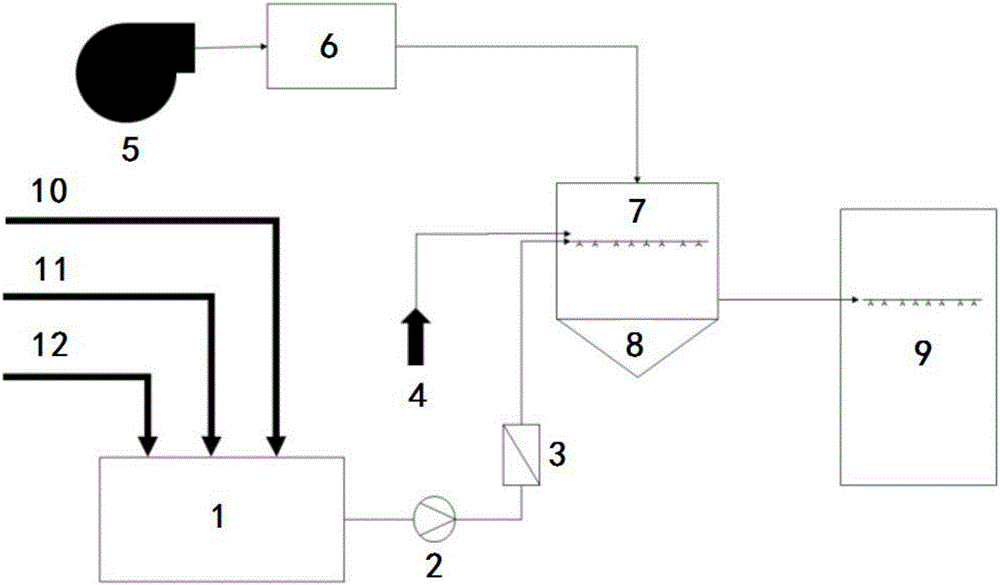

[0028] like figure 1 The device shown is used to control the blockage of the air preheater of the coal-fired power plant boiler, and is connected to the boiler tail flue 9, including the mixing box 1, the water pump 2, the filter 3, the air compression pump 4, the blower 5, the heater 6, The evaporator 7 and the ash hopper 8; the air compression pump 4 is connected to the top of the side wall of the evaporator 7 through the compressed air nozzle, the stirring box 1 is communicated with the compressed air nozzle through a pipeline, and the mixing box 1 and the compressed air nozzle are provided in the middle Water pump 2 and filter 3, agitator 1 are also provided with three pipelines 10, 11, 12 for adding fly ash, process water and alkaline substances; described blower 5 communicates with evaporator 7 top through heater 6, evaporates The lower part of the side wall of the device 7 communicates with the boiler tail flue 9 through a connecting pipe, and the bottom of the evaporat...

Embodiment 2

[0037] The fly ash collected by the dust collector is added to the stirring tank according to the liquid-solid ratio of 4:1 and stirred to form a slurry. The stirring tank is equipped with heat preservation measures and electric heating devices to control the temperature of the slurry between 40-50°C; after the slurry is stable, add hydrogen Sodium oxide adjusts slurry pH to 13;

[0038] The evaporator is arranged vertically, the hot air flows from top to bottom, and flows out from the side outlet of the lower part, and a dust hopper is set at the bottom;

[0039] The air is pressurized by the blower and enters the heater. After heating, it is sprayed into the tail flue of the boiler through the evaporator to form a stable air flow, and the temperature of the gas in the evaporator is controlled between 240-250°C;

[0040] The alkaline slurry is pumped through the filter and then sent to the compressed air atomizing nozzle. The compressed air pressure is 0.04Mpa. After evaporat...

Embodiment 3

[0043] The fly ash collected by the dust collector is added to the stirring tank according to the liquid-solid ratio of 10:1 and stirred to make a slurry. The stirring tank is equipped with heat preservation measures and electric heating devices to control the temperature of the slurry between 30-40°C; after the slurry is stable, add carbonic acid Sodium to adjust the slurry pH to 8;

[0044] The evaporator is arranged vertically, the hot air flows from top to bottom, and flows out from the side outlet of the lower part, and a dust hopper is set at the bottom;

[0045] After desulfurization, the clean flue gas is condensed and dewatered, and then led to the heater by a fan. After heating, it is sprayed into the tail flue of the boiler through the evaporator to form a stable air flow, and the gas temperature in the evaporator is controlled between 260-280 °C;

[0046] The alkaline slurry is pumped through the filter and then sent to the compressed air atomizing nozzle. The comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com