Feed mold removal agent and preparation method thereof

A mold remover and feed technology, applied in the field of feed mold remover and its preparation, can solve the problems of inability to effectively curb the harm of mycotoxins, ignoring the immunosuppressive effect of mycotoxins, and relatively different use effects, so as to improve animal disease resistance. Ability, slow corrosion and irritation, adsorption effect enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

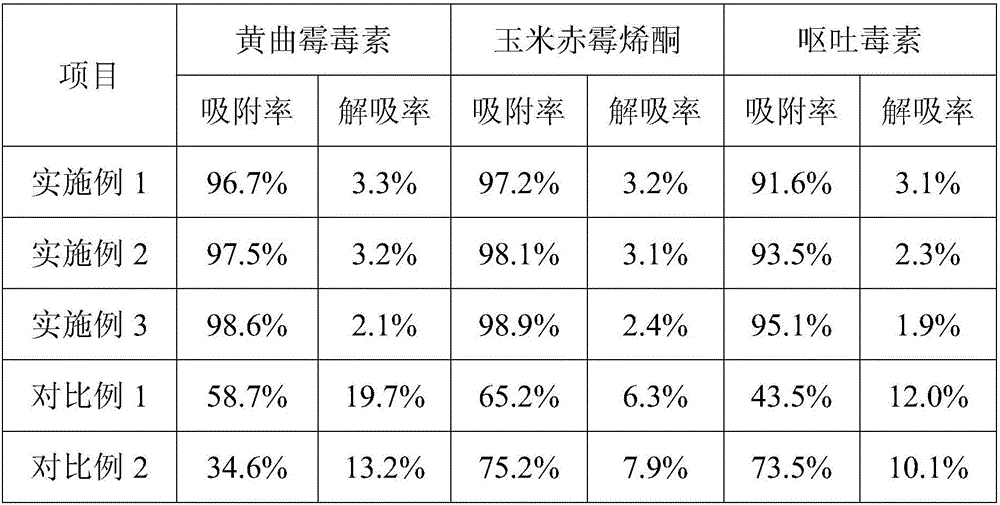

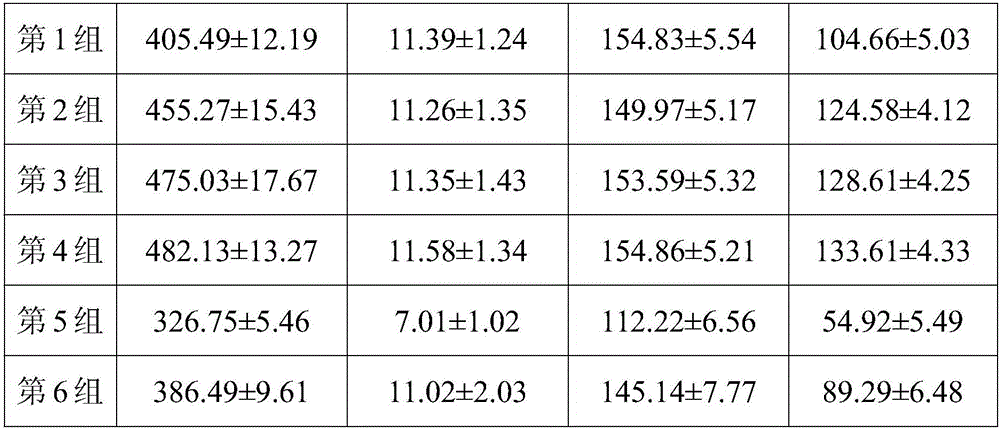

Examples

Embodiment 1

[0028] A kind of preparation method of feed mildew remover, described raw material is calculated by weight percentage, comprises the steps:

[0029] (1) Preparation of organic acid montmorillonite: crush sodium-based montmorillonite, add a mixed solution of ethanol and benzene with a volume ratio of 1:2, stir at 65°C and 1000rpm for 20 minutes to mix evenly, within 0.5 hours Slowly add benzoic acid of 30% of the mass of the sodium montmorillonite, and continue to react for 1 hour after the addition; after the reaction is completed, filter, wash with absolute ethanol for 2 to 3 times, and dry in vacuum to obtain the organic acid montmorillonite;

[0030] (2) Add 15 parts of Bacillus, 30 parts of Lactobacillus, 10 parts of humic acid and add water to stir and mix for 15 minutes, add 20 parts of chitosan and stir to dissolve, use ultrasonic vibration to react for 20 minutes, the ultrasonic temperature is 45 °C, and the ultrasonic power is 300 rpm; Static filtration, drying under ...

Embodiment 2

[0035] A kind of preparation method of feed mildew remover, described raw material is calculated by weight percentage, comprises the steps:

[0036] (1) Preparation of organic acid montmorillonite: crush the sodium montmorillonite, add a mixed solution of ethanol and benzene with a volume ratio of 1:2, stir at 70°C and 500rpm for 20min to mix evenly, within 1.5 hours Slowly add a mixed solution of sorbic acid and fumaric acid with 50% of the mass of sodium montmorillonite, and continue to react for 2 hours after the addition; after the reaction is completed, filter, wash with absolute ethanol for 2 to 3 times, and vacuum dry to obtain the organic acid Montmorillonite;

[0037] (2) Mix 20 parts of Bacillus, 15 parts of Lactobacillus, and 20 parts of humic acid with water for 10 minutes, add 40 parts of cyclodextrin and stir to dissolve, and react with ultrasonic vibration for 30 minutes. The ultrasonic temperature is 35 °C and the ultrasonic power is 100 rpm; Static filtration, ...

Embodiment 3

[0042] A kind of preparation method of feed mildew remover, described raw material is calculated by weight percentage, comprises the steps:

[0043] (1) Preparation of organic acid montmorillonite: crush sodium-based montmorillonite, add a mixed solution of ethanol and benzene with a volume ratio of 1:3, stir at 80°C and 1000rpm for 10 minutes to mix evenly, within 2 hours Slowly add the mixed solution of 80% sodium montmorillonite mass of acrylic acid and gluconic acid, and continue to react for 1 hour after the addition is completed; after the reaction is completed, filter, wash with absolute ethanol for 2 to 3 times, and vacuum dry to obtain organic acid montmorillonite stone;

[0044] (2) Mix 30 parts of Bacillus, 20 parts of Lactobacillus and 15 parts of humic acid with water for 15 minutes, add 30 parts of sodium alginate and stir to dissolve, and react with ultrasonic vibration for 20 minutes, the ultrasonic temperature is 45 °C, and the ultrasonic power is 100 rpm; St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com