Cationic electro-deposition coating

A cationic electrodeposition and coating technology, applied in electrophoretic coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of not showing good applicability, the substrate adhesion and weather resistance of the coating film need to be further improved, etc. Achieve the effects of excellent electrodeposition coating adaptability, excellent substrate adhesion, and high wet film resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] 1. Preparation of amino-modified novolac epoxy resin

[0032] components Dosage (g) Novolak epoxy resin (EEW=165-175) 218 Epoxy resin (EEW=180-190) 2180 Bisphenol A 860 cardanol 156.2 Bisphenol A polyoxyethylene ether 1 460 methyl isobutyl ketone 100 Dimethylbenzylamine 3 methyl isobutyl ketone 400 N-Methylethanolamine 189.4 ketimine 2 231.2 Ketimine modified polyamide 3 420 Ethylene glycol monobutyl ether 250 total 5467.8

[0033] 1-bisphenol A polyoxyethylene ether: hydroxyl value = 220-230mgKOH / g, Mn = 480-550.

[0034] 2-Ketimine: It is produced by the reaction of diethylenetriamine and propiophenone. The solid content of the final product is 70%, and the amine value is 335-360mgKOH / g.

[0035] 3-Ketimine modified polyamide: American Air Sunmide 3155, amine value 230-270mgKOH / g.

[0036] In a reaction flask equipped with a thermometer, a stirrer and a reflux condenser, sequ...

Embodiment 2

[0047] 1. Preparation of amino-modified novolac epoxy resin

[0048] components Dosage (g) O-Cresol Novolak Epoxy Resin (EEW=200-210) 264 Epoxy resin (EEW=180-190) 2180 Bisphenol A 860 cardanol 156.2 Bisphenol A polyoxyethylene ether 1 460 methyl isobutyl ketone 100 Dimethylbenzylamine 3 methyl isobutyl ketone 400 N-Methylethanolamine 189.4 ketimine 2 231.2 Ketimine modified polyamide 3 420 Ethylene glycol monobutyl ether 250 total 5513.8

[0049] 1-bisphenol A polyoxyethylene ether: hydroxyl value = 220-230mgKOH / g, Mn = 480-550.

[0050] 2-Ketimine: It is produced by the reaction of diethylenetriamine and propiophenone. The solid content of the final product is 70%, and the amine value is 335-360mgKOH / g.

[0051] 3-Ketimine modified polyamide: American Air Sunmide 3155, amine value 230-270mgKOH / g.

[0052] In a reaction flask equipped with a thermometer, a stirrer and a reflux conden...

Embodiment 3

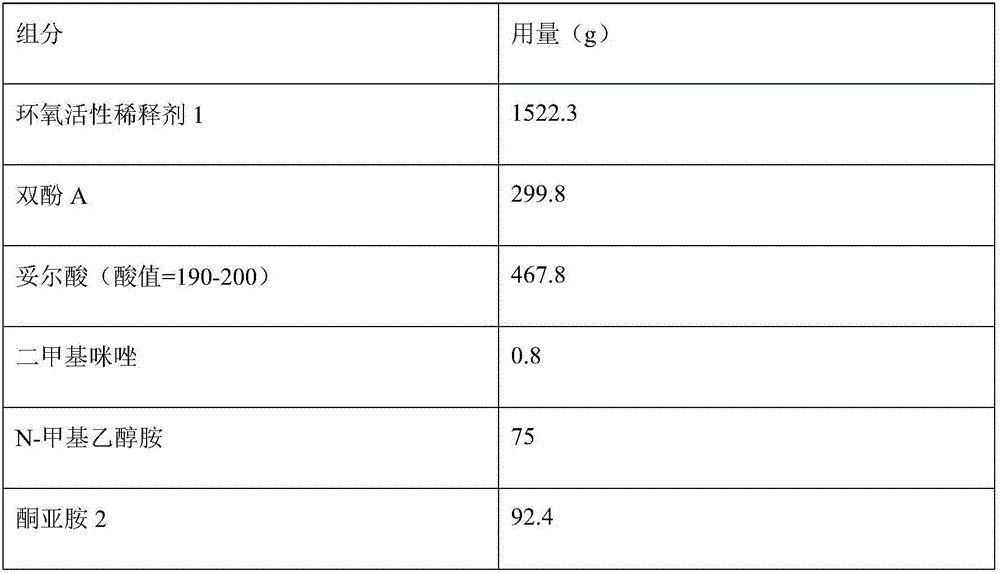

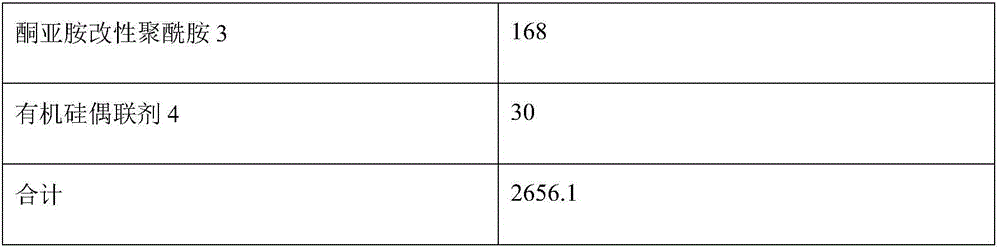

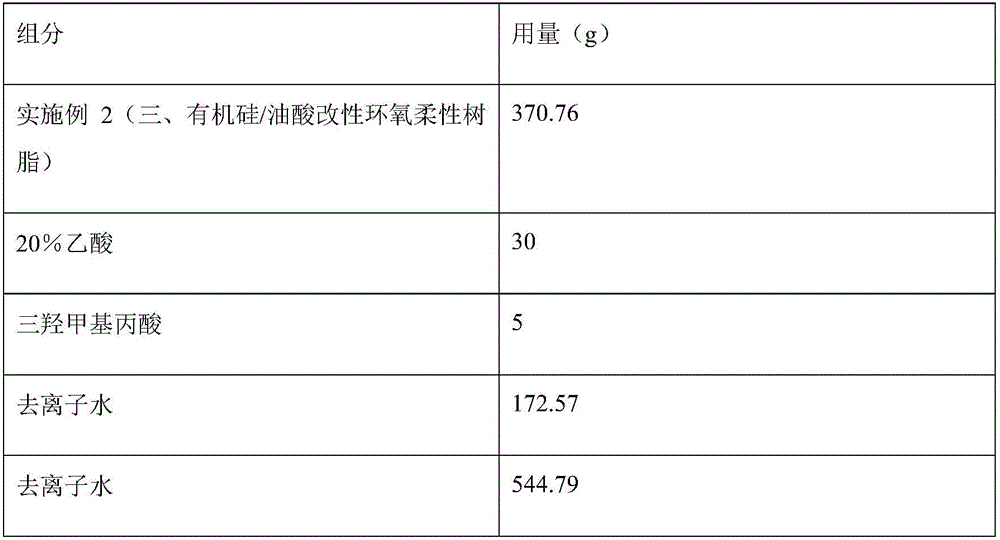

[0064] 1. Silicone / oleic acid modified epoxy flexible resin

[0065]

[0066]

[0067] 1-Epoxy reactive diluent: polypropylene glycol diglycidyl ether manufactured by DOW Company, EEW=290-300, total chlorine content<2000ppm.

[0068] 2-Ketimine: prepared by reacting diethylenetriamine and methyl isobutyl ketone, the solid content of the final product is 70%, and the amine value is 450-480mgKOH / g.

[0069] 3-Ketimine modified polyamide: American Air Sunmide 3155, amine value 230-270mgKOH / g.

[0070] 4-Organosilicon coupling agent: epoxy functional group silane KH560.

[0071] In the reaction flask equipped with a thermometer, agitator and reflux condenser, add the epoxy reactive diluent and bisphenol A in the prescribed amount in sequence. After the addition is complete, start stirring to raise the temperature of the reaction system to 100°C and then add dimethylimidazole After adding the catalyst, first raise the temperature to 170°C to react for 35 minutes and then me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com