Preparation method of MCM-41 modified carbon paste electrode and application of MCM-41 modified carbon paste electrode in electrochemical detection of ceftriaxone

A technology of MCM-41 and carbon paste electrodes, applied in the direction of material electrochemical variables, etc., can solve the problem of poor sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

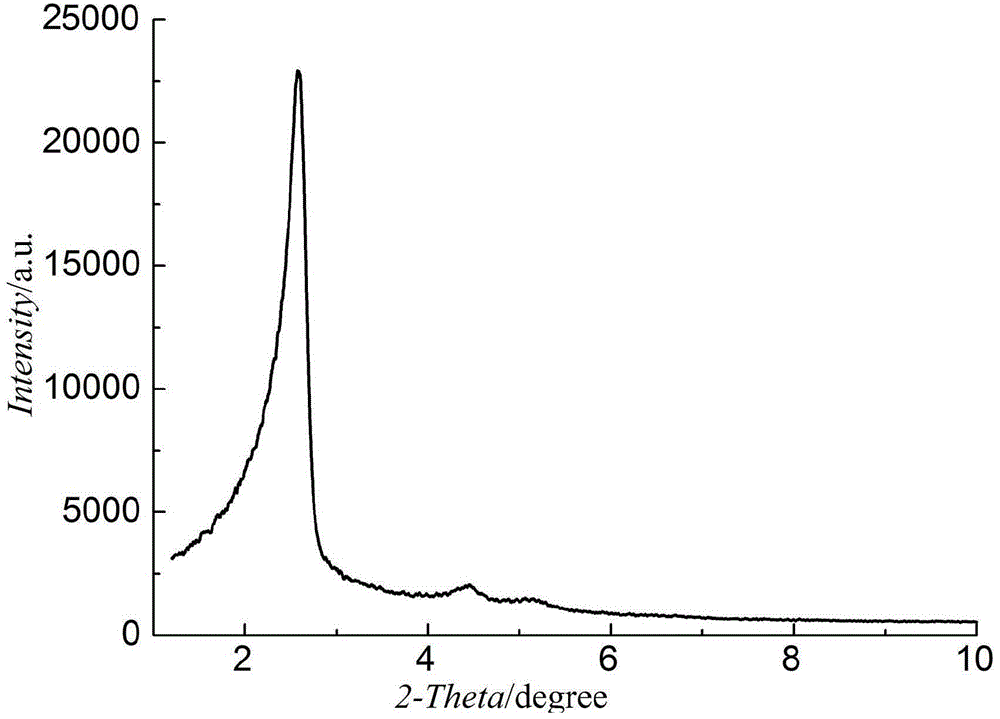

[0011] Example 1 : Preparation of MCM-41 Mesoporous Molecular Sieve

[0012] Use ammonia water as an alkali source to adjust pH, the steps of hydrothermal synthesis are as follows (the ratio of raw materials is as follows): Weigh 1.20 g CTAB into a 100 mL three-necked flask with a balance, add 50 mL distilled water, 60 o C water bath heating, magnetic stirring until CTAB dissolves. Under stirring conditions, add 25% ammonia water to adjust the pH to 10.2. After mixing, slowly add 5 mL TEOS dropwise, and a white precipitate is gradually formed. Continue to stir for 6 hours, then take it out, filter it on a circulating water multipurpose vacuum pump, and continuously rinse with hot distilled water to obtain the original all-silicon MCM-41 molecular sieve powder. After drying at room temperature, put the obtained semi-finished product into a porcelain crucible and place it in a muffle furnace for 250 o Bake at C for 2 h, then at 600 o It is calcined at C for 4 hours, taken out, an...

Embodiment 2

[0013] Example 2 : Preparation of bare electrodes

[0014] Weigh 1.0 g of graphite powder with a balance into an agate mortar to grind. During the grinding process, proceed in one direction as much as possible. When the graphite powder is no longer a fine powder, add 5-6 drops of silicone oil. , Continue to grind, and try to grind in one direction as much as possible when grinding again. At the same time, avoid the graphite powder from being brought out of the mortar due to excessive force. When the graphite powder in the mortar is found to be in good flake shape, stop grinding, and put the ground graphite powder into a glass tube with an inner diameter of 5 mm and a length of 8 cm, compact it with a thin glass rod, and insert a copper wire , Use weighing paper to polish the other end of the electrode brightly, set aside.

Embodiment 3

[0015] Example 3 : Preparation of MCM-41 Mesoporous Molecular Sieve Modified Electrode

[0016] Use a balance to weigh 0.10 g of MCM-41 mesoporous molecular sieve white powder and 0.90 g of graphite powder in an agate mortar. After the white powder is not visible, add 6 drops of silicone oil drop by drop, mix well and continue grinding. After grinding evenly and sufficiently, put it into a glass tube and compact it with a glass rod. Cut a piece of copper wire, sand it with sandpaper to remove the dirt and oxides on the surface of the copper wire until the surface of the copper wire is bright. Wrap an insulating tape around 1cm so that it fits into one end of the glass tube. Insert the copper wire into the carbon powder. The surface of the tape and the carbon powder are the same. Pick up. After making the electrodes, label them for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com