Chitosan-quaternary-ammonium-salt antibacterial agent and antibacterial liquid, preparing technology of chitosan-quaternary-ammonium-salt antibacterial agent and preparing technology of chitosan-quaternary-ammonium-salt antibacterial liquid

A chitosan quaternary ammonium salt and a preparation process technology, which can be applied to local antibacterial agents, medical preparations containing active ingredients, organic active ingredients, etc. and other problems, to achieve the effect of improved antibacterial performance, good cross-linking effect and good reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Add methyl ethyl ketone oxime to dry methyl ethyl ketone, and then slowly drop it into isophorone diisocyanate. Preferably, the ratio of mass parts of active hydrogen and -NCO is controlled to be n(H):n(NCO)=0.55:1, and the dropwise addition temperature is controlled not to exceed 40 degrees, then slowly heated to 80 degrees, cooled, and prepared for used for subsequent reactions at room temperature. The product in this step can be referred to as product one, and its degree of reaction can be measured by the di-n-butylamine method.

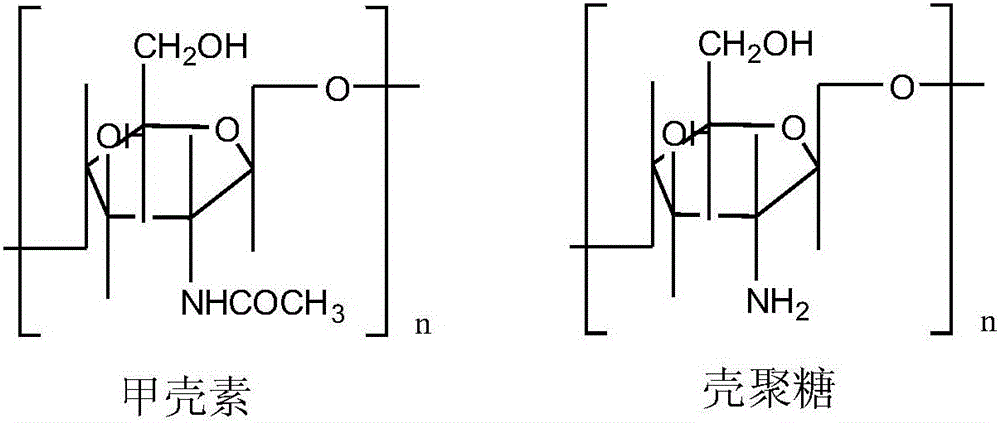

[0029] 2. Add 100ml of isopropanol, 5 grams of chitosan and appropriate amount of glycidyltrimethylammonium chloride into the three-necked bottle. Preferably, the mass ratio of chitosan and glycidyltrimethylammonium chloride is controlled to be 1:3-4, the reaction temperature is 70-80 degrees, and the time is 5-8 hours, and then it can be suction filtered, Wash thoroughly with ethanol and dry. The product in this step can be referred ...

Embodiment 2

[0032] The main difference between this embodiment and Embodiment 1 is that the chitosan quaternary ammonium salt antibacterial substance is liquid, that is, the chitosan quaternary ammonium salt antibacterial liquid. The chitosan quaternary ammonium salt antibacterial liquid preparation process can be prepared as an antibacterial agent by the process of Example 1, and then according to conventional methods, such as being dissolved in water and stirring to make a liquid chitosan quaternary ammonium salt antibacterial liquid. In addition, the chitosan quaternary ammonium salt antibacterial solution can also adopt the process in Example 1, only correspondingly omitting the steps of dehydration such as drying and drying. Other similarities will not be repeated here.

Embodiment 3

[0034] This embodiment is one of the specific applications of the first embodiment. The chitosan quaternary ammonium salt antibacterial agent (abbreviated as antibacterial agent) is dissolved in water, stirred, and the antibacterial agent is soaked in a ratio of 0.1-1% of the cloth weight and a bath ratio of 7-10, dehydrated, and dried at 90 degrees. Bake at 120 degrees for 30 minutes to get chitosan quaternary ammonium antibacterial fabric (abbreviated as antibacterial fabric). The antibacterial performance test was carried out according to the FZ73023 standard, and the antibacterial rate of Escherichia coli was as follows after washing 50 times:

[0035] Sample serial number 1 2 3 Antibacterial rate 55.42 67.44 99.99

[0036] Sample 1 is chitosan and commercially available blocking isocyanate Bayer company 3100; Sample 2 is that chitosan does not carry out the quaternization of step 2, and directly chitosan grafts blocking monoisocyanate; Sample 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com