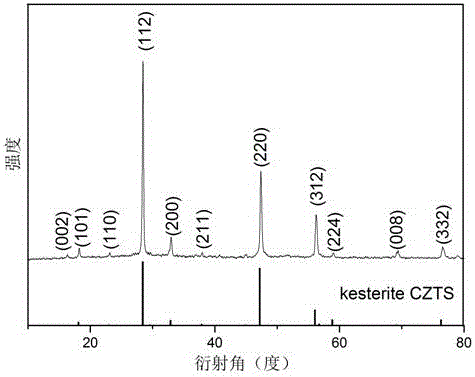

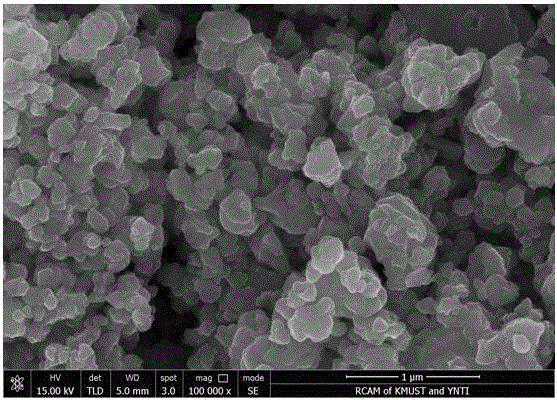

Method for rapidly preparing copper-zinc-tin-sulfur nanoparticles

A copper-zinc-tin-sulfur, nanoparticle technology, applied in nanotechnology, chemical instruments and methods, tin compounds, etc., can solve the problems of long time and complex process, and achieve the effect of short reaction time, simple equipment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a method for rapidly preparing copper-zinc-tin-sulfur nanoparticles, which specifically includes the following steps:

[0030] (1) 1.6 mmol copper chloride dihydrate (CuCl 2 • 2H 2 O), 1.5 mmol acetic acid dihydrate (Zn(CH 3 COO) 2 • 2H 2 O), 1.25 mmol tin chloride dihydrate (SnCl 2 • 2H 2 O), 6 mmol thiourea (CS(NH 2 ) 2 ) was dissolved in a beaker containing a mixed solution of 6 mL ethylene glycol and 60 mL triethylenetetramine, adding a stirring magnet, stirring with a magnetic stirrer and an ultrasonic cleaner in turn, the magnetic stirring speed was 800 rpm, and the ultrasonic treatment frequency was 40 KHz, ultrasonic 10min, make the solution fully mixed to obtain a clear solution;

[0031] (2) Add 0.5g of surfactant polyethylene glycol to the precursor obtained in step (1), mix evenly and set aside;

[0032] (3) Put the solution obtained in step (2) into a microwave oven, and set the reaction system parameters as follows: the mi...

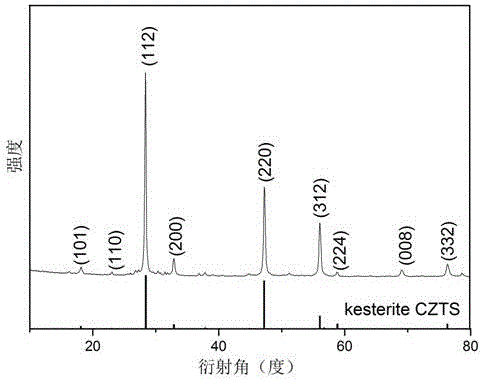

Embodiment 2

[0037] This embodiment provides a method for rapidly preparing copper-zinc-tin-sulfur nanoparticles, which specifically includes the following steps:

[0038] (1) 2 mmol copper nitrate hydrate (Cu(NO 3 ) 2 •2.5H 2 O), 1.25 mmol zinc nitrate (Zn(NO 3 ) 2 •6H 2 O), 1mmol tin acetate (C 4 h 6 o 4 Sn), 6 mmol sodium sulfide (Na 2 S•9H 2 O) Dissolve in a beaker containing a mixed solution of 6 mL of ethylene glycol and 24 mL of triethylenetetramine, add a stirring magnet, stir with a magnetic stirrer and an ultrasonic cleaner in sequence, the magnetic stirring speed is 600 rpm, and the ultrasonic treatment frequency is 40 KHz, ultrasonic 5min, so that the solution is fully mixed to obtain a clear solution;

[0039] (2) Add 1g of surfactant polyvinylpyrrolidone to the above precursor obtained in step (1), mix evenly and set aside;

[0040] (3) Put the solution obtained in step (2) into a microwave oven, and set the reaction system parameters as follows: the microwave powe...

Embodiment 3

[0046] This embodiment provides a method for rapidly preparing copper-zinc-tin-sulfur nanoparticles, which specifically includes the following steps:

[0047] (1) 2mmol copper acetylacetonate (Cu(acac) 2 ), 1 mmol zinc chloride (Zn(Cl) 2 ), 1 mM diacetylacetonate tin chloride (Sn(acac) 2 Cl 2 ), 5mmol thioacetamide (C 2 h 5 NS) was dissolved in a beaker containing a mixed solution of 18 mL ethylene glycol and 24 mL triethylenetetramine, adding a stirring magnet, stirring with a magnetic stirrer and an ultrasonic cleaner in sequence, the magnetic stirring speed was 500 rpm, and the ultrasonic treatment frequency was 40 KHz, ultrasonic 20min, make the solution fully mixed to obtain a clear solution;

[0048] (2) Add a mixture of surfactants 0.026g polyethylene glycol and 0.026g ethanolamine to the precursor obtained in step (1), mix evenly and set aside;

[0049] (3) Put the solution obtained in step (2) into a microwave oven, and set the reaction system parameters as foll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com