Building wall overall pouring material and construction method thereof

An integral pouring and building technology, applied in the field of building materials, can solve the problems of cement-based materials such as large dry shrinkage, high water absorption, and difficulty in ideal cost performance, and achieve simple and easy construction methods, good foaming and micro-expansion work, The effect of excellent waterproof and anti-seepage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

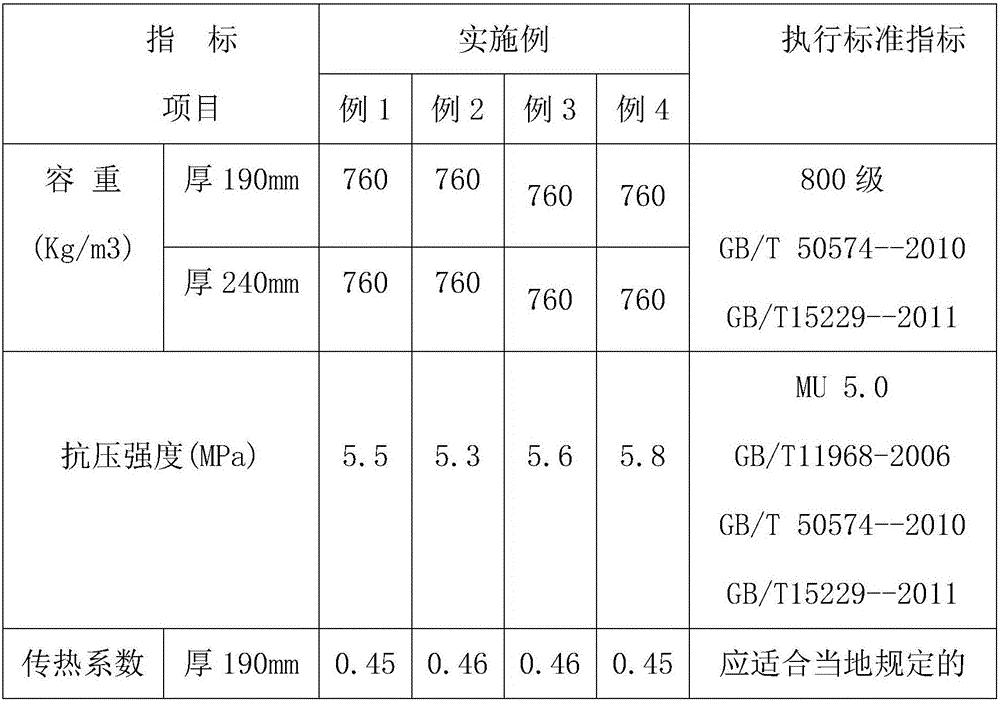

Examples

Embodiment 1

[0022] An integral pouring material for a building wall proposed by the present invention includes the following raw materials in weight percentage: 3% of vitrified microbeads, 3% of rice husk, 4% of additives, 7% of cement, 17% of fly ash above grade 3, lime 3%, slag powder 2%, iron slag 8%, and the balance is hemihydrate gypsum.

[0023] The additive is a compound additive, and the weight percentage of each component is: sodium methyl silicate 4%, silane water-repellent agent 5%, melamine water forming agent 3%, alkali inhibitor 8%, acrylic emulsion 12%, lithium carbonate 7%, Ammonium borate 9%, calcium chloride 7%, polyvinyl alcohol 12%, alum 4%, and the balance is sodium hydroxide.

[0024] Its construction method comprises the following steps:

[0025] S1. Put the vitrified microbeads, rice husk, cement, fly ash above grade 3, lime, slag micropowder, iron slag and hemihydrate gypsum in the dry powder mixer in the weight percentage and fully stir to form a mixed dry powde...

Embodiment 2

[0030] A building wall integral pouring material proposed by the present invention comprises the following raw materials in weight percentage: 7% of vitrified microbeads, 4% of additives, 9% of cement, 16% of fly ash above grade 3, 3% of lime, and slag powder 3%, steel slag 7%, and the balance is hemihydrate gypsum.

[0031] The additive is a compound additive, and the weight percentage of each component is: sodium methyl silicate 3%, silane water-repellent agent 4%, melamine water forming agent 1%, alkali inhibitor 6%, acrylic emulsion 14%, lithium carbonate 8%, Ammonium borate 8%, calcium chloride 9%, polyvinyl alcohol 14%, alum 3%, and the balance is sodium hydroxide.

[0032] Its construction method comprises the following steps:

[0033] S1. Put the vitrified microspheres, cement, fly ash above grade 3, lime, slag powder, steel slag and hemihydrate gypsum in the dry powder mixer in the weight percentage and fully stir to form a mixed dry powder;

[0034] S2. Support and...

Embodiment 3

[0038] An integral pouring material for a building wall proposed by the present invention includes the following raw materials in weight percentage: 7% of vermiculite, 1% of polystyrene particles, 4% of additives, 10% of cement, 10% of fly ash above grade 3, and 3% of lime. %, 3% slag powder, 6% steel slag, and the balance is hemihydrate gypsum.

[0039] The additive is a composite additive, and the weight percentage of each component is: sodium methyl silicate 5%, silane water-repellent agent 6%, melamine water forming agent 2%, alkali inhibitor 7%, acrylic emulsion 13%, lithium carbonate 6%, Ammonium borate 9%, calcium chloride 8%, polyvinyl alcohol 10%, alum 5%, and the balance is sodium hydroxide.

[0040] Its construction method comprises the following steps:

[0041] S1. Put the vermiculite, polystyrene particles, cement, fly ash above grade 3, lime, slag micropowder, steel slag and hemihydrate gypsum in the dry powder mixer in the weight percentage and fully stir to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com