Preparation method of preservative for living plants

A technology of plant preservatives and antistaling agents, which is applied in the field of preparation of living plant antistaling agents, can solve the problems of difficulty in knowing the effect of antistaling agents on fresh flowers, complicated process, high cost of raw materials, etc., achieve green and environmental preservation effect, and be friendly to the application environment , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

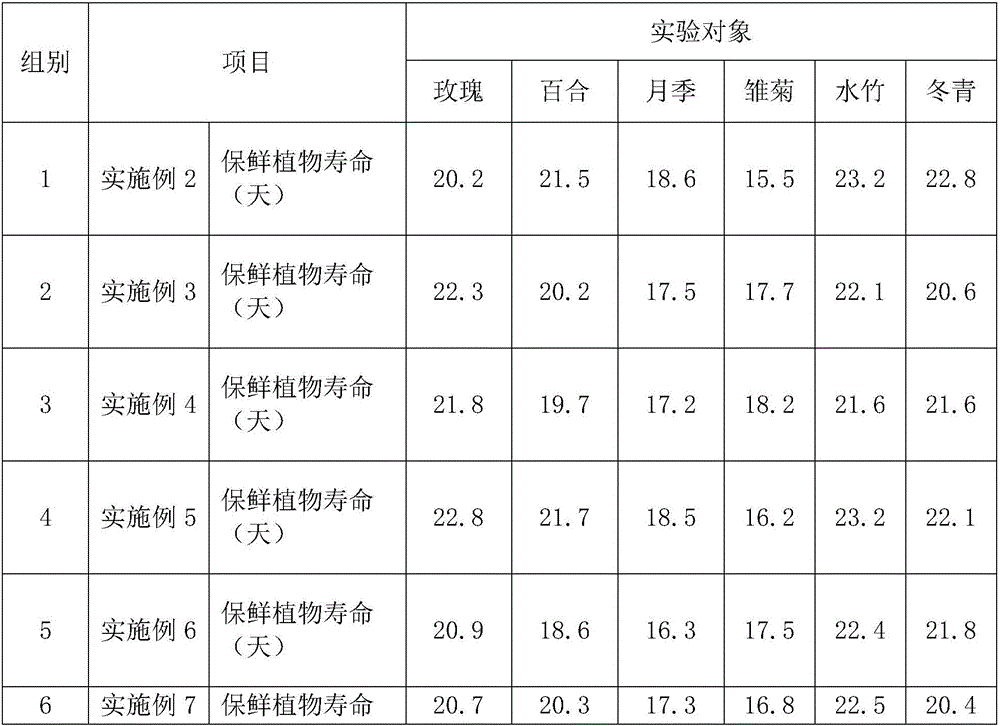

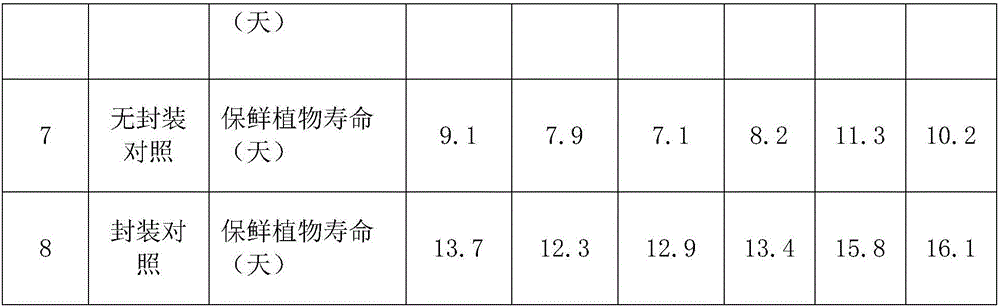

Examples

Embodiment 1

[0017] The preparation process of the living plant antistaling agent involved in this embodiment is as follows: the raw material weight percentage of the antistaling agent is as follows, commercially available sodium pyroglutamate 1-5%, the weight percentage concentration is 50% ethanol aqueous solution 2-4%, garlic juice 1 -3%, fresh tobacco leaf juice 1-2%, dichlorvos 0.2-0.5%, kerosene 0.1-0.2%, the rest is distilled water, the sum is 100%; when preparing garlic juice, first mix 1 part of fresh garlic and 2 parts of distilled water Squeeze it into juice, then use a 400-mesh sieve to remove solid impurities, and make garlic juice for later use; when preparing fresh tobacco leaf juice, first mix 1 part of fresh tobacco leaves with 2 parts of distilled water and squeeze it into juice, then use a 400-mesh sieve Remove solid impurities by silk filtration, and prepare tobacco leaf juice for later use; add the raw materials in a mixing tank in turn, mix and stir for 5-10 minutes un...

Embodiment 2

[0024] The preservative preparation process and method of use involved in the living plant antistaling agent described in this embodiment are the same as in Example 1, and the raw materials and weight percentages thereof are as follows: commercially available sodium pyroglutamate 1%, the concentration by weight is 50 % ethanol aqueous solution 2%, garlic juice 1%, fresh tobacco leaf juice 1%, dichlorvos 0.2%, kerosene 0.1%, distilled water 94.7%.

Embodiment 3

[0026] The preservative preparation process and method of use involved in the living plant antistaling agent described in this embodiment are the same as in Example 1. The raw materials and weight percentages of the preservative are as follows: commercially available sodium pyroglutamate is 5%, and the concentration by weight is 50% % ethanol aqueous solution 4%, garlic juice 3%, fresh tobacco leaf juice 2%, dichlorvos 0.5%, kerosene 0.2%, distilled water 85.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com