Patents

Literature

32 results about "Pyroglutamic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pyroglutamic acid (also known as PCA, 5-oxoproline, pidolic acid) is a ubiquitous but little studied natural amino acid derivative in which the free amino group of glutamic acid or glutamine cyclizes to form a lactam. The names of pyroglutamic acid conjugate base, anion, salts, and esters are pyroglutamate, 5-oxoprolinate, or pidolate.

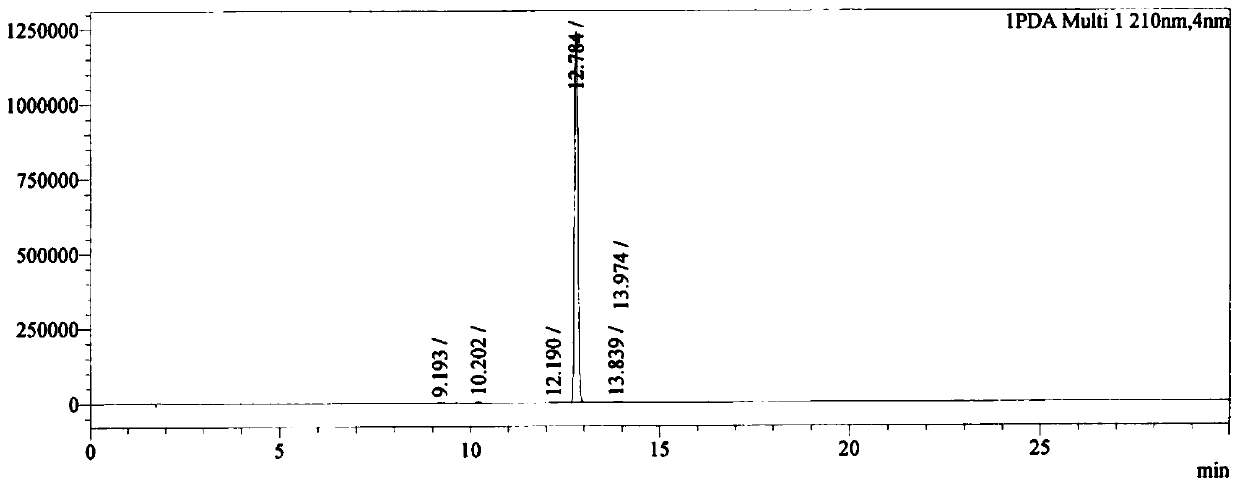

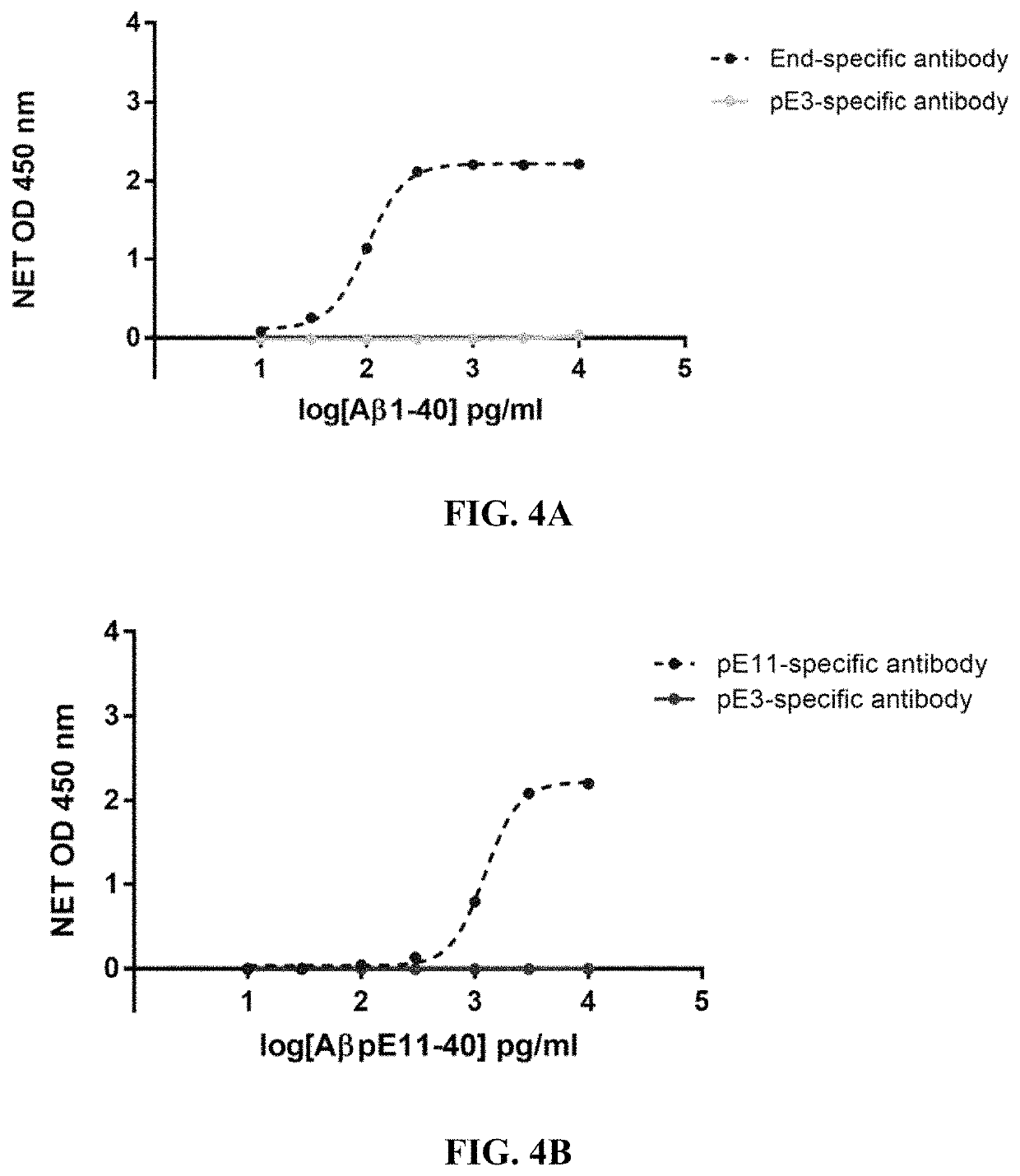

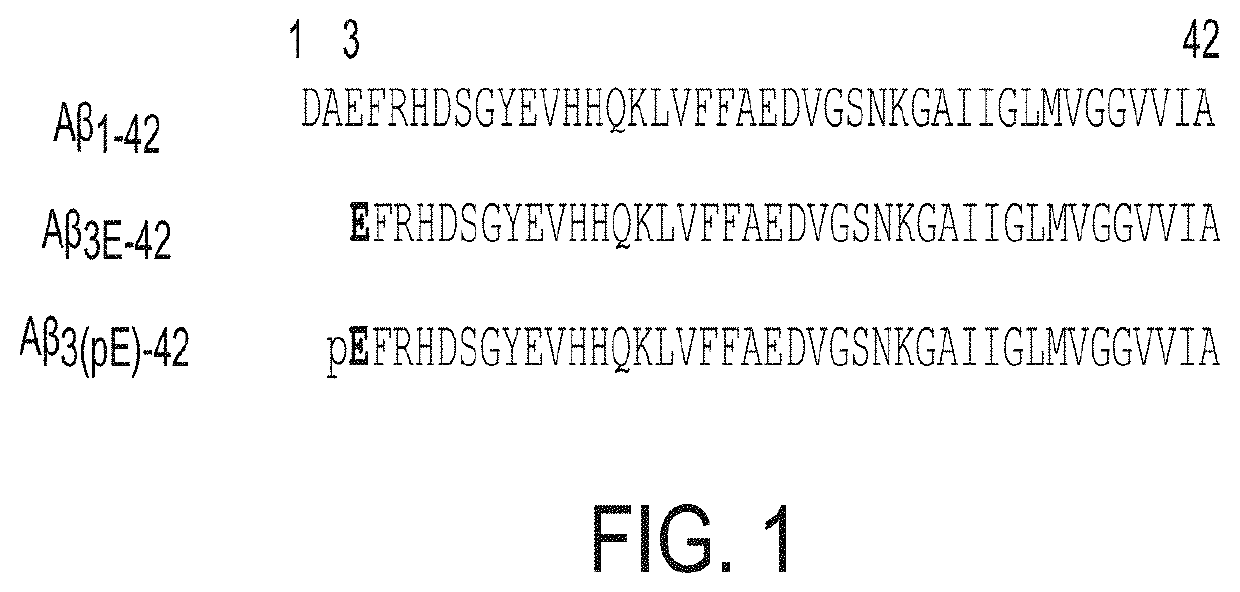

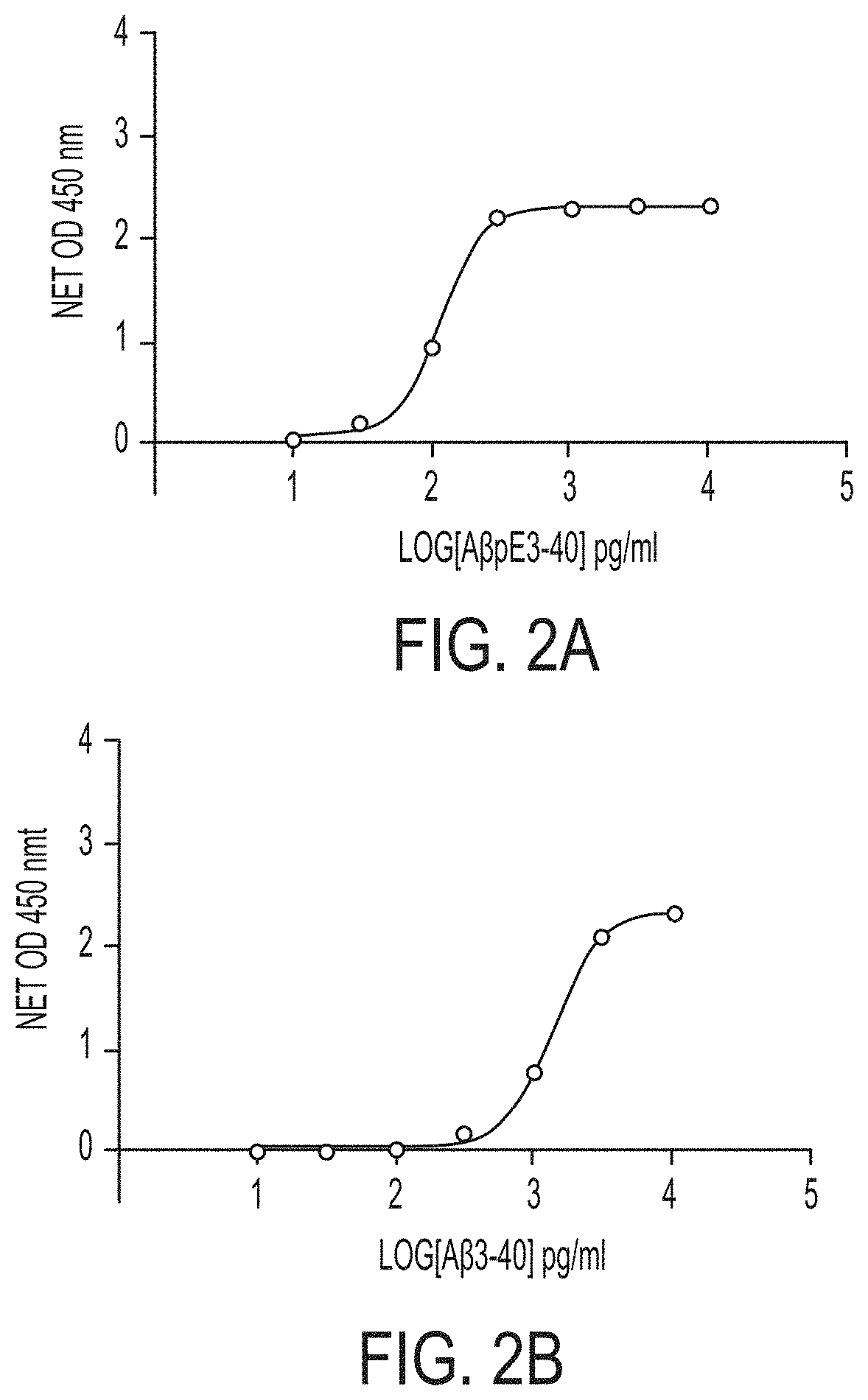

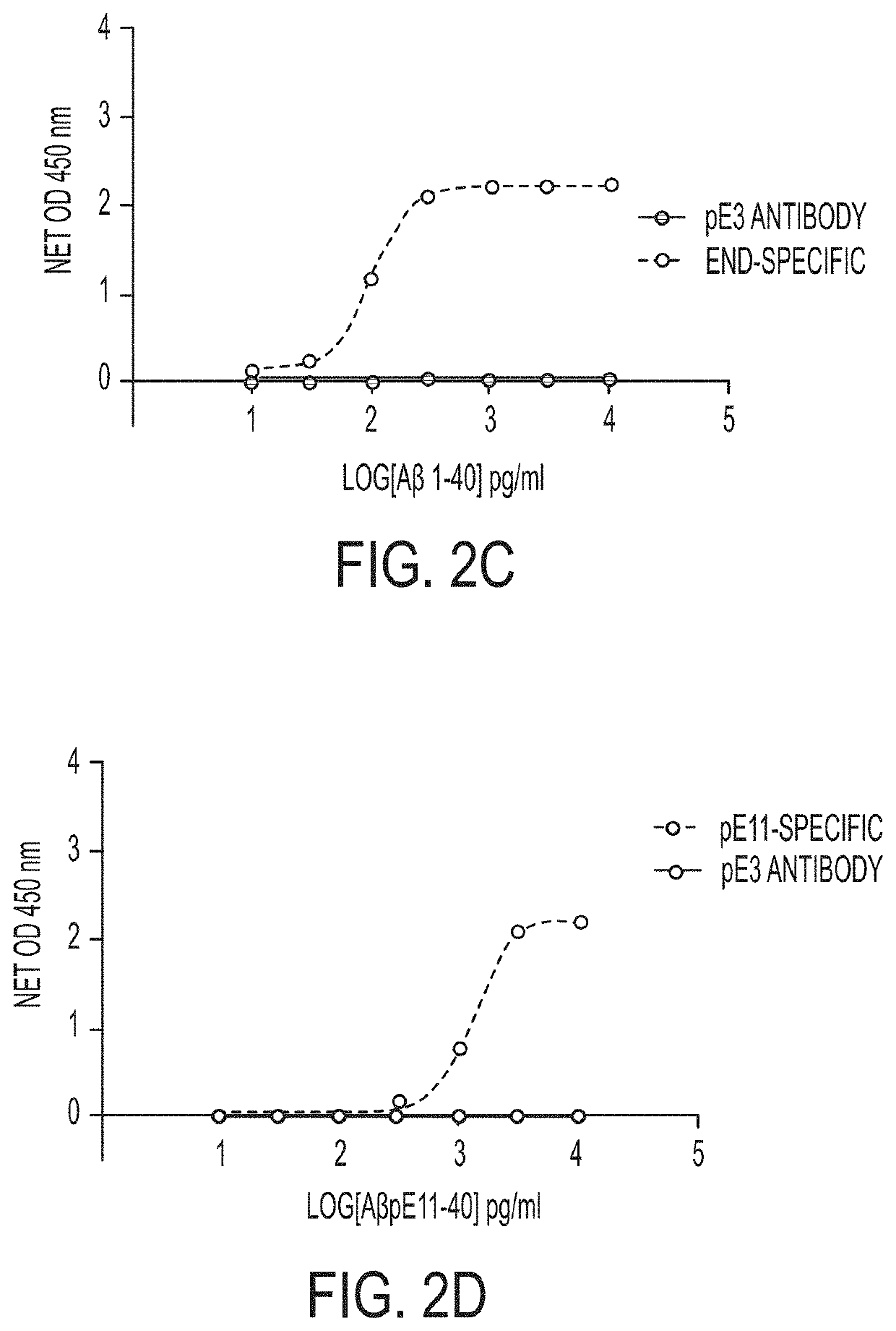

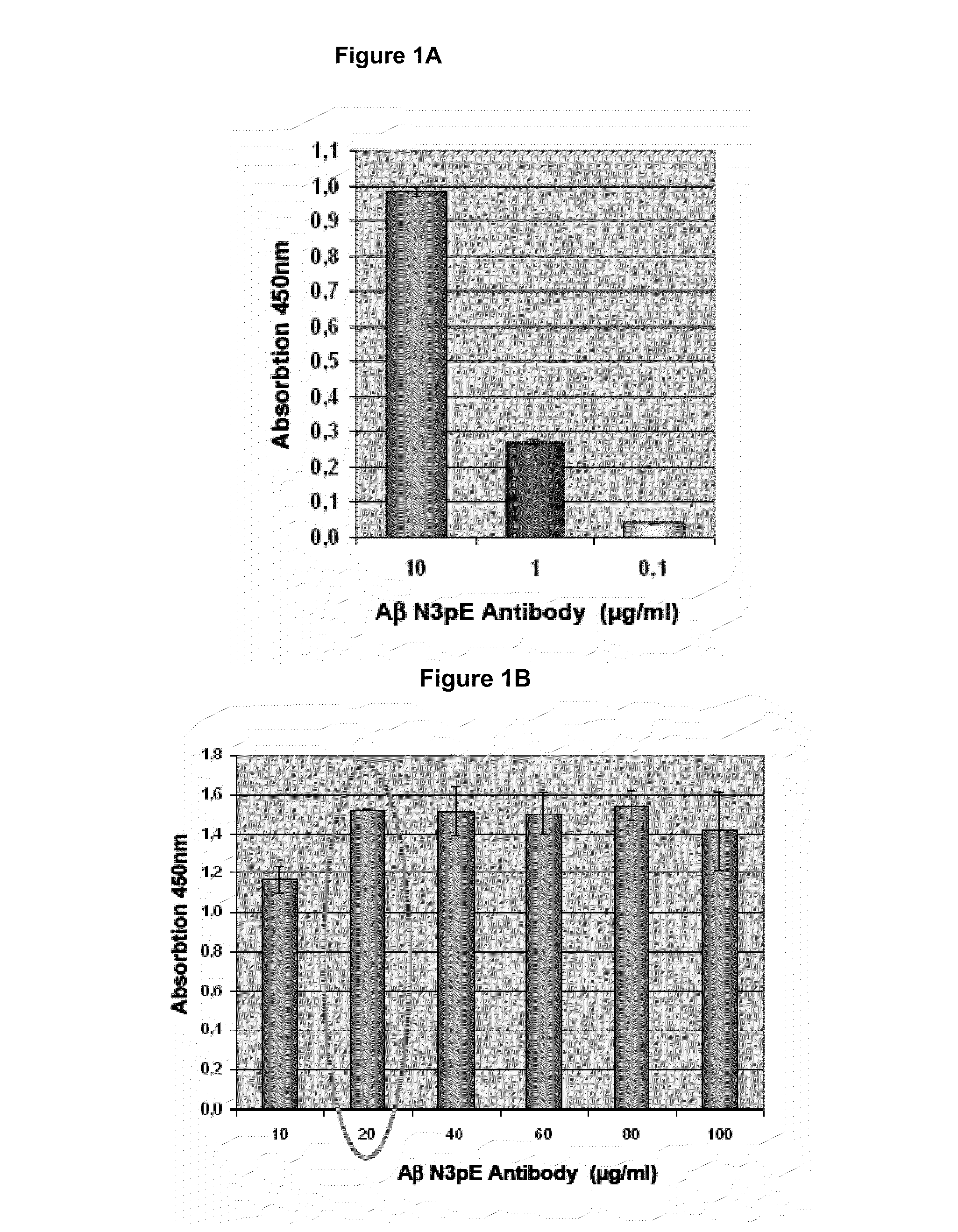

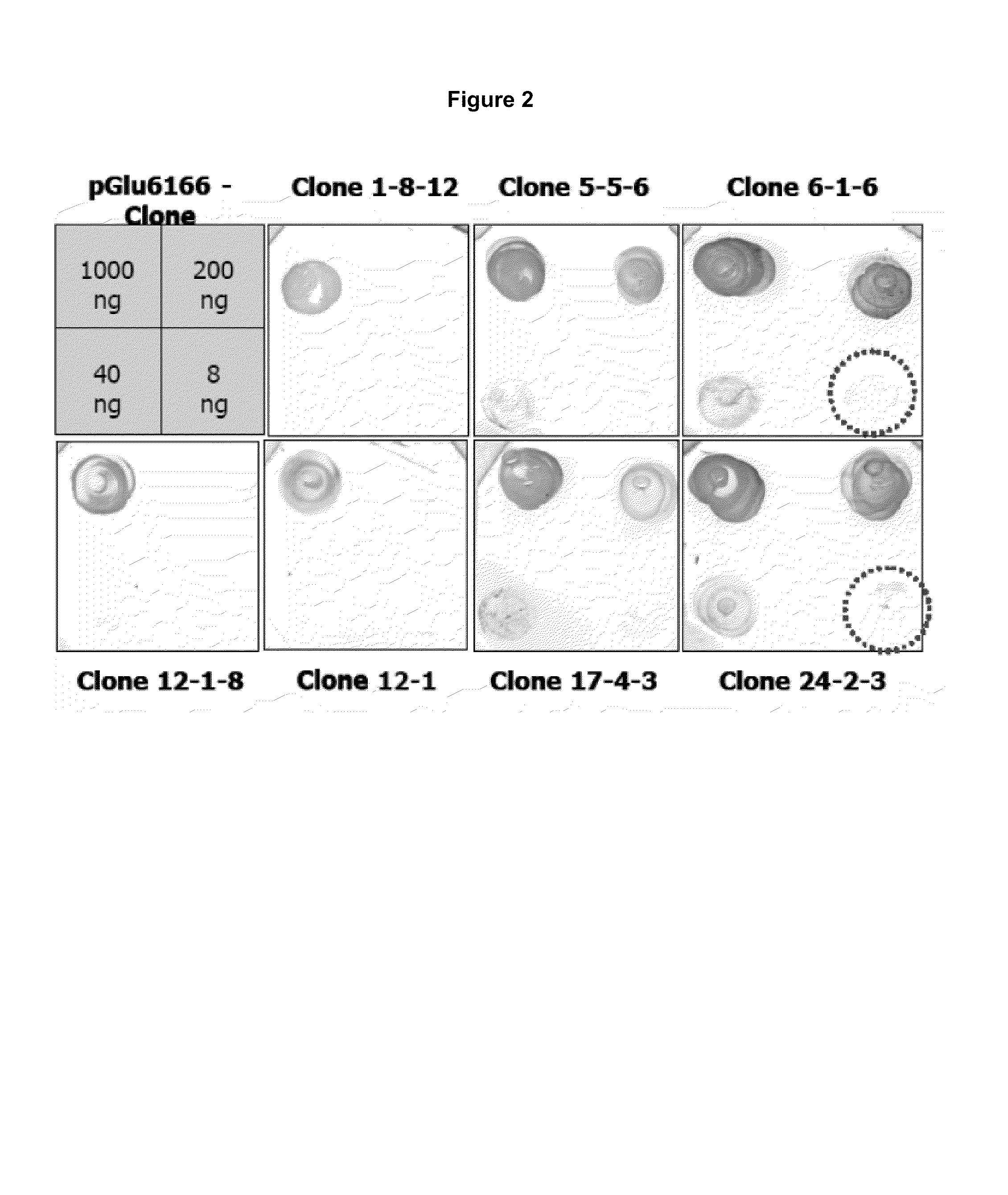

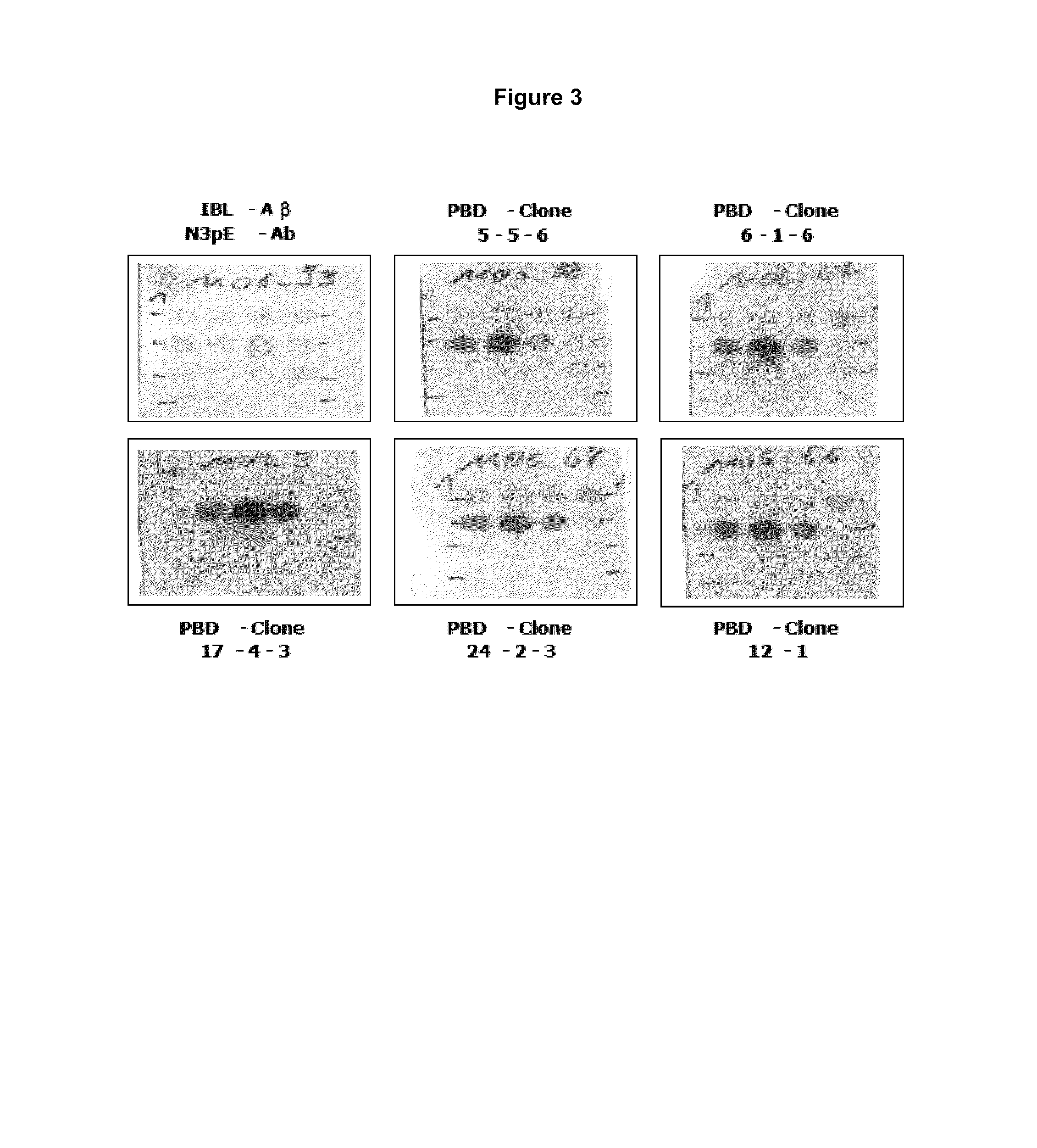

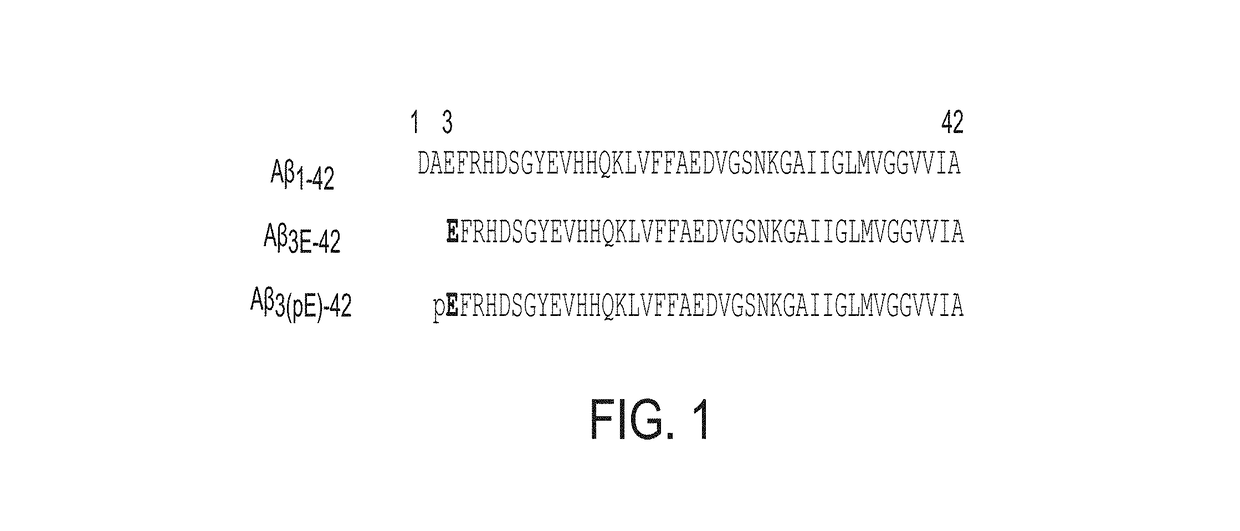

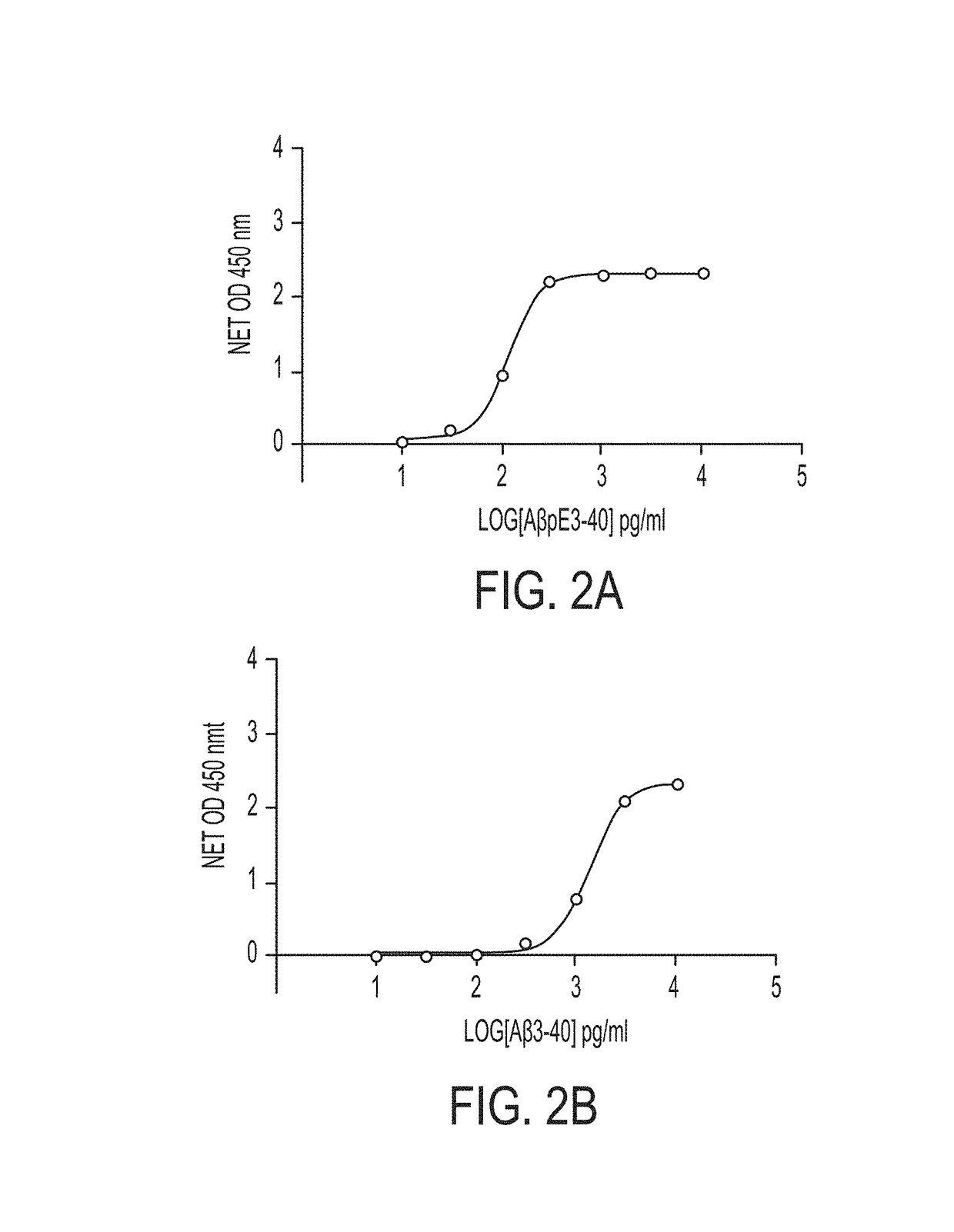

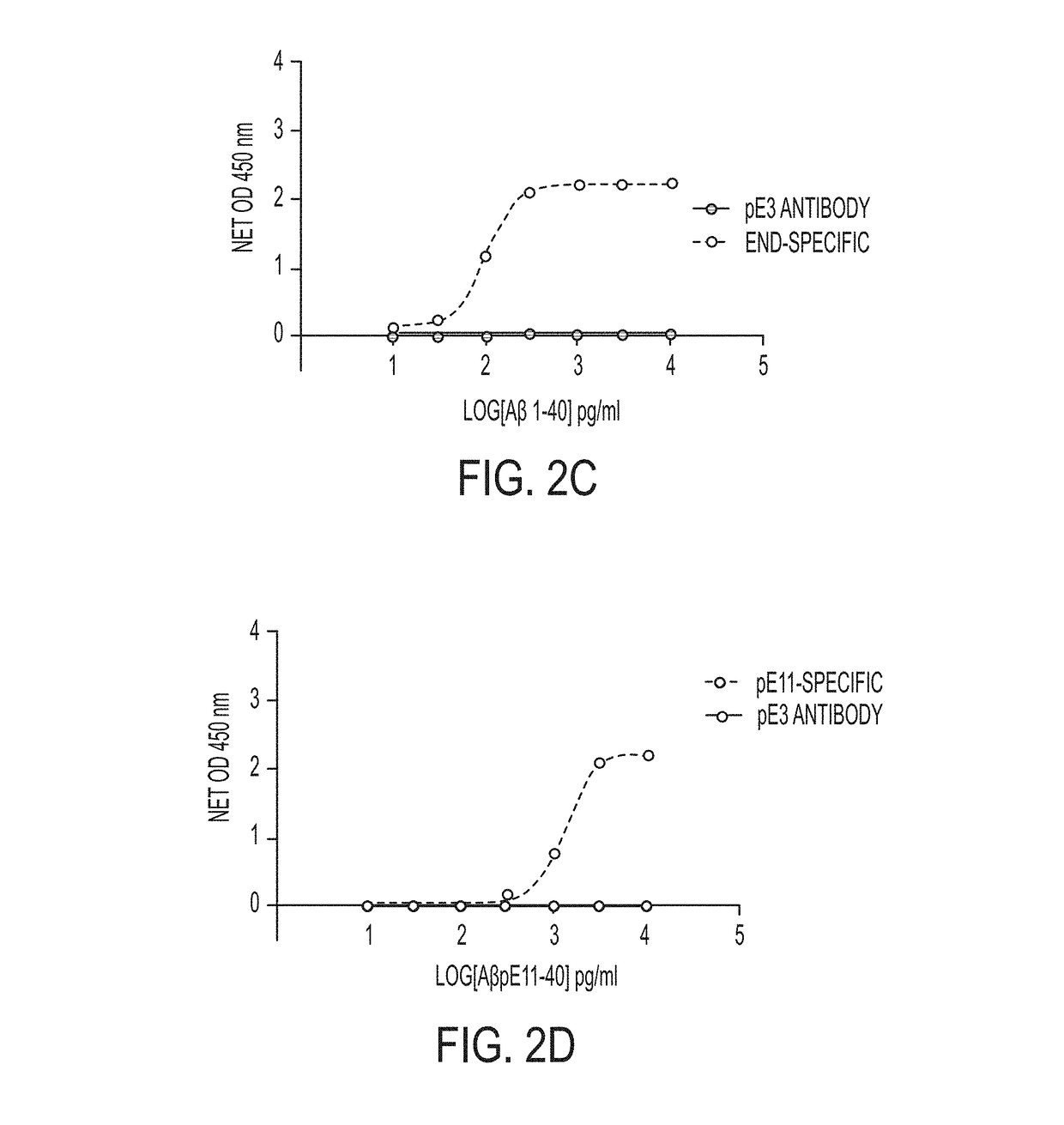

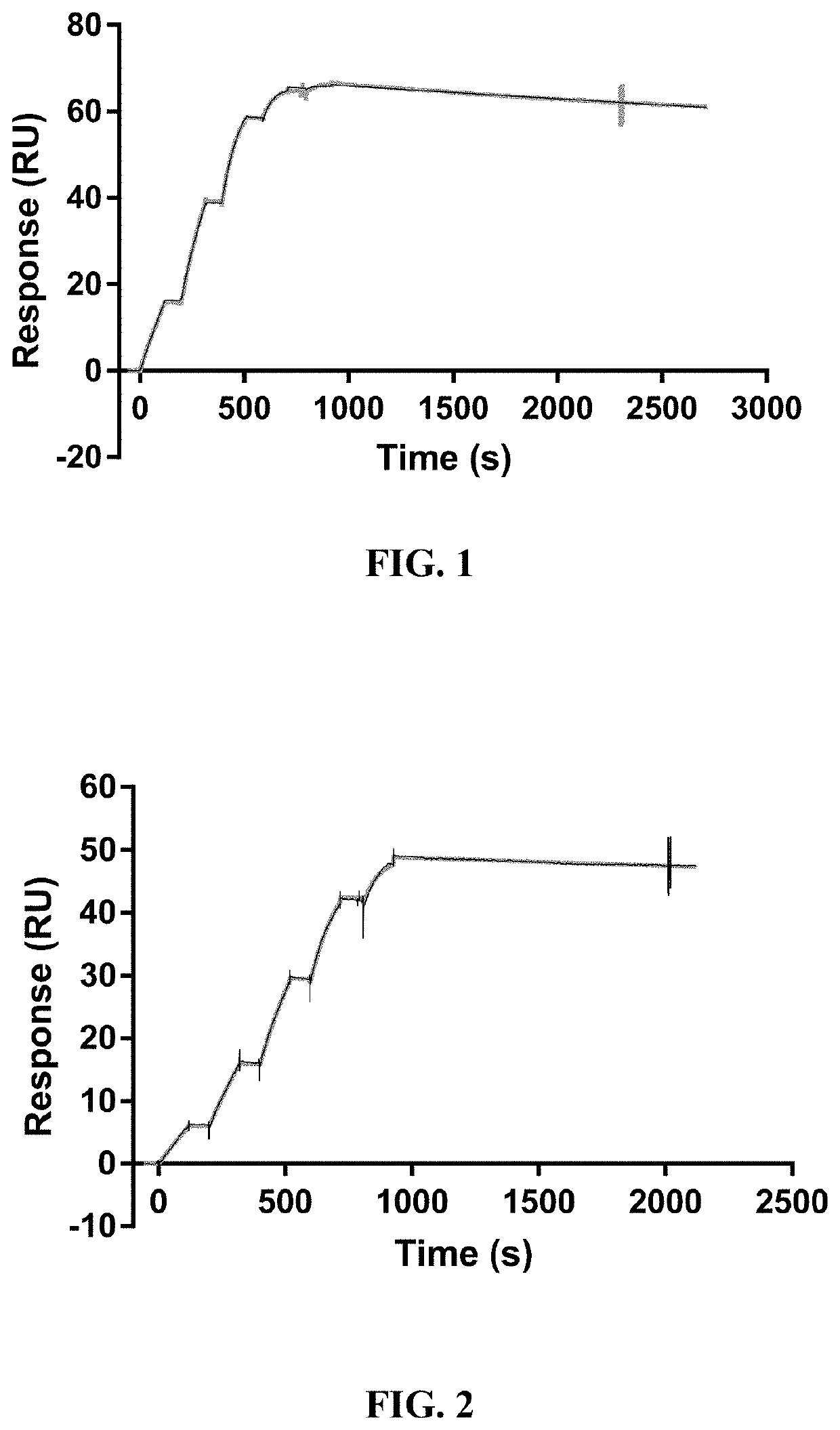

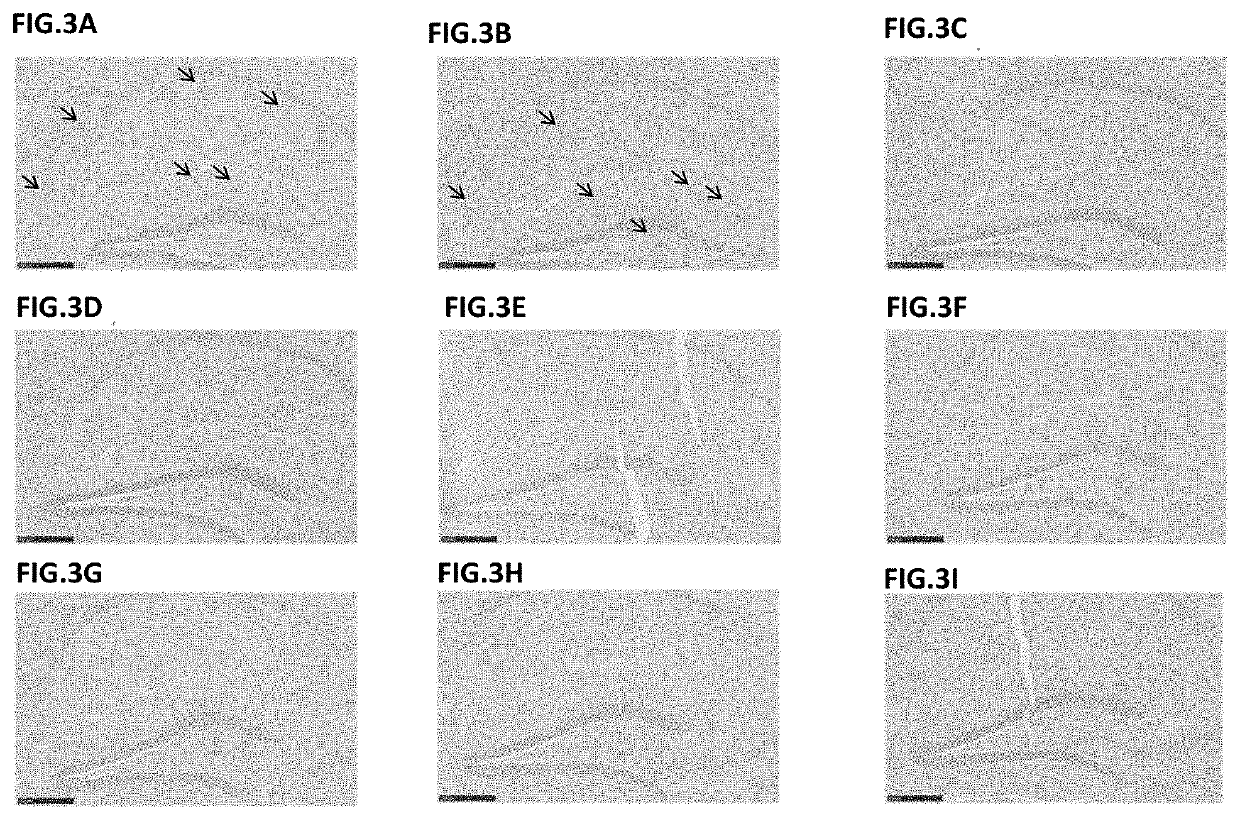

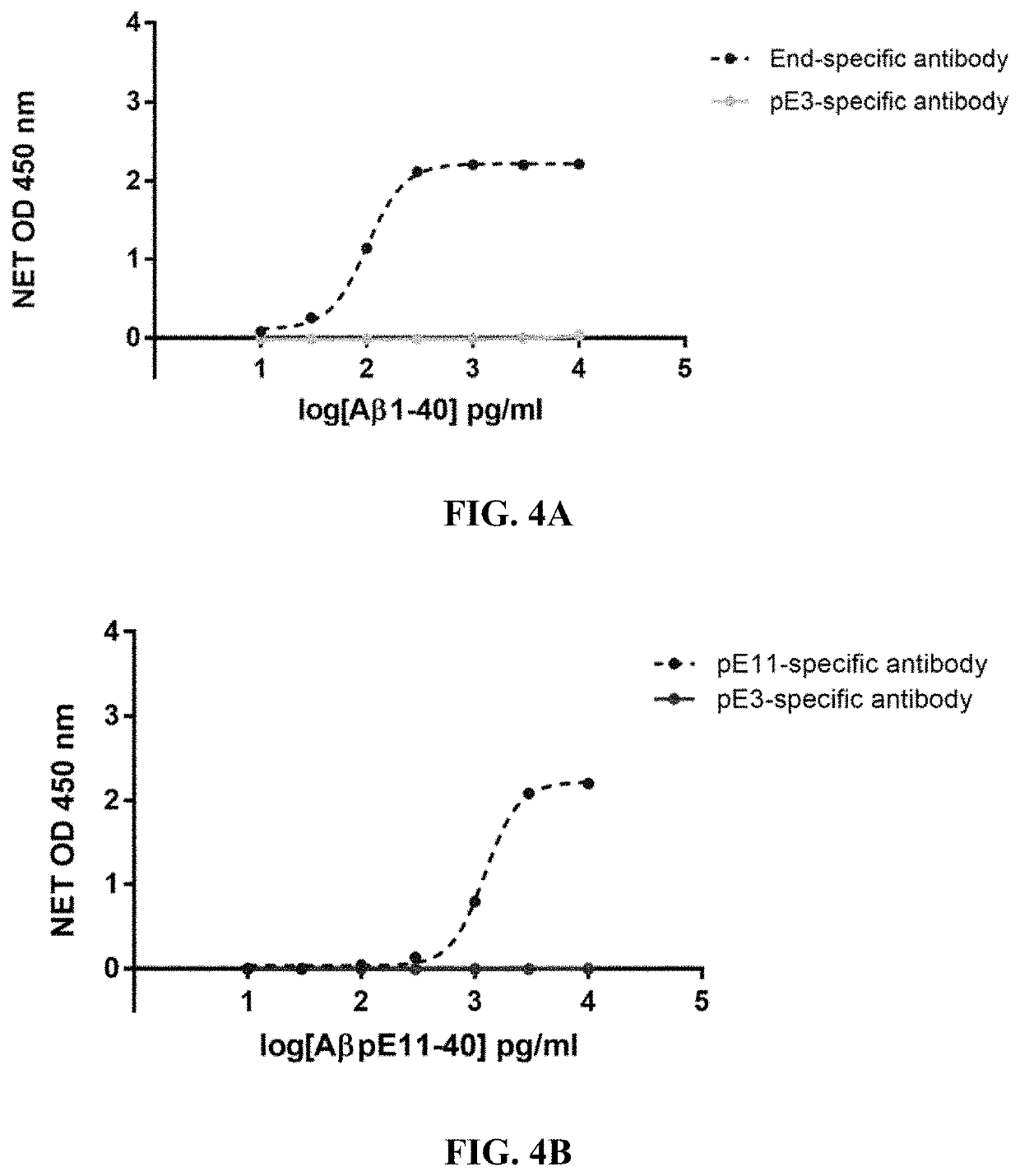

Antibodies specific for N-terminal truncated and pyroglutamate modified amyloid-beta peptides

The present invention pertains to novel diagnostic assays for the diagnosis of amyloidosis, in particular Alzheimer's disease, and related aspects. In particular, monoclonal antibodies and an antibody assay are provided.

Owner:VIVORYON THERAPEUTICS NV

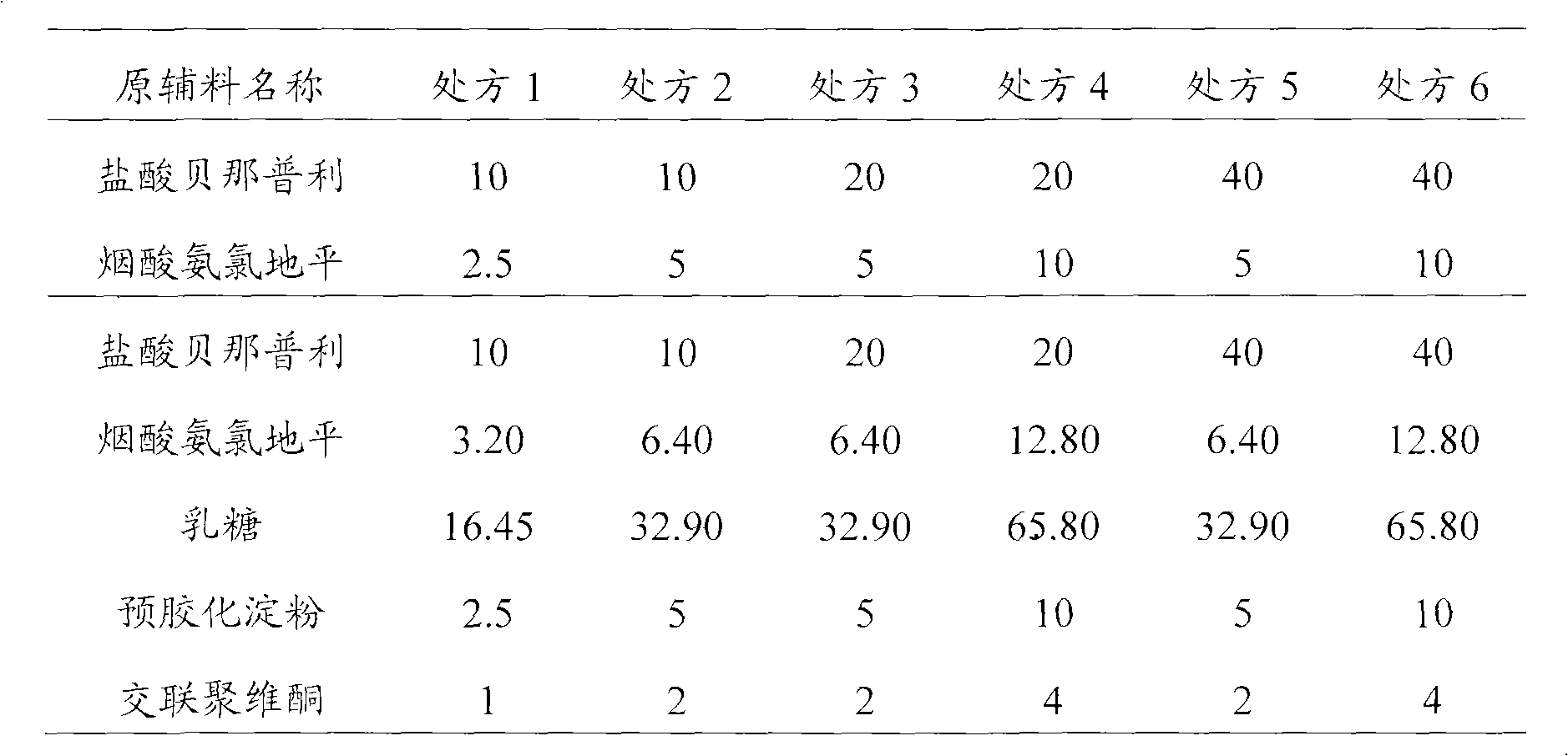

Treatment composition containing amlodipine series salt and pril medicament

InactiveCN101653440AMetabolism disorderHeterocyclic compound active ingredientsL-AspartateAmlodipine

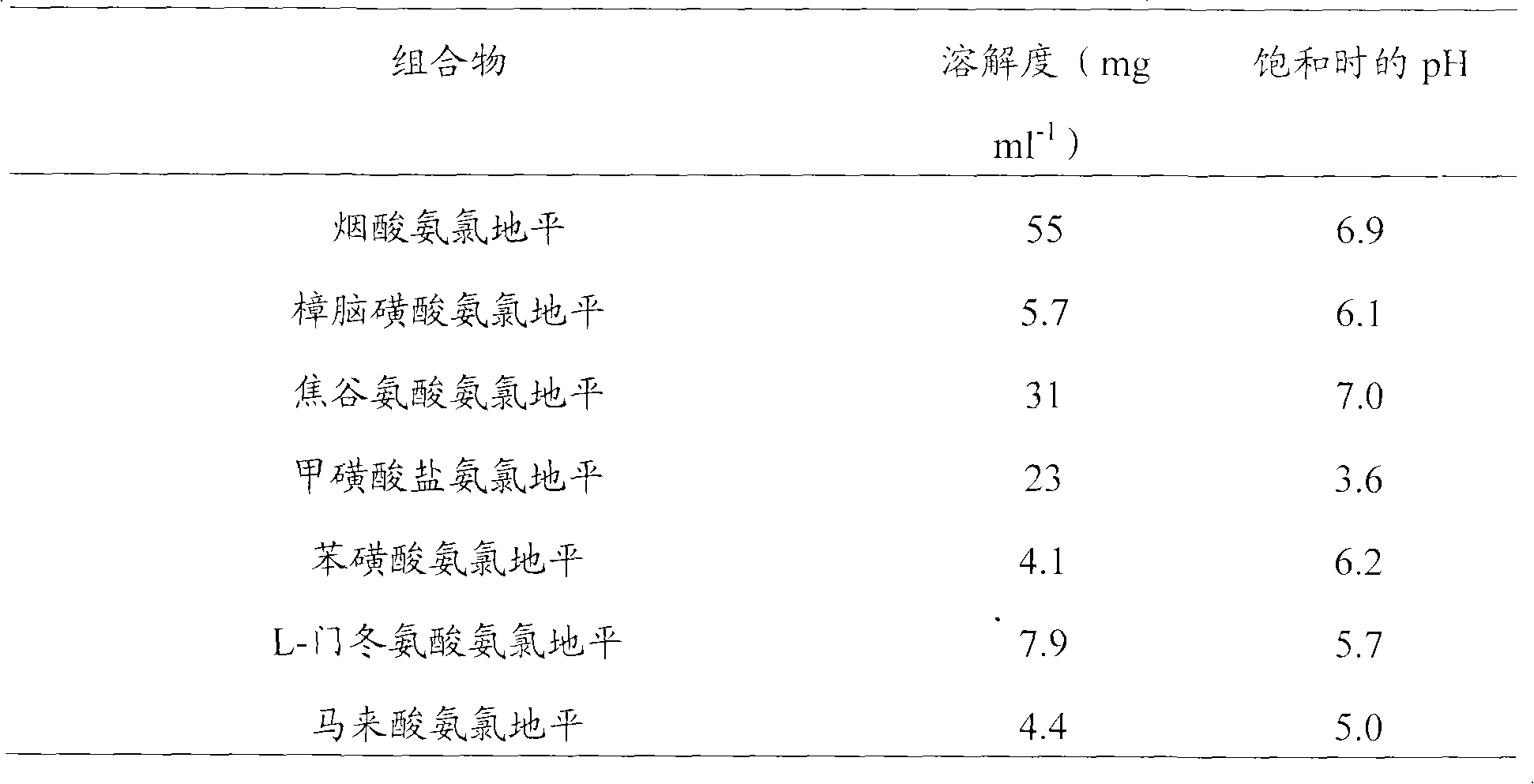

The invention relates to an amlodipine series salt, which particularly comprises nicotinate, camsilate, pyroglutamate, L-aspartate, maleate and mesylate. The invention also relates to a pril compoundor a pharmaceutical composition of a medicinal salt of the pril compound and a preparation method thereof, and a drug combination medicine box containing a composition of the amlodipine series salt and a composition of sartan compounds. The composition of the invention comprises the following components: a) a certain amount of an amlodipine salt; b) a certain amount of the pril compound or a medicinal salt of the pril compound; and c) a medicinal carrier or a diluting agent. The composition or the medicine box can be used for treating the patients suffering from hypertension, angina pectoris,atherosclerosis, and / or hypersphyxia and treating the patients (including the human beings) having heart danger symptoms.

Owner:BEIJING ROCK PHARMA

Adsorption carrier for recycling of metal in waste lithium ion batteries and preparation method thereof

InactiveCN108636375ALow costOther chemical processesWaste accumulators reclaimingAcetic acidHydrogen

The invention belongs to the technical field of recycling of waste lithium batteries, and particularly relates to an adsorption carrier for recycling of metal in waste lithium ion batteries and a preparation method thereof. The preparation method comprises the following steps of (1) mixing chitosan and pyroglutamic acid, adding water to dissolve, adding an acid solution, adjusting the pH (potential of hydrogen) value to 4.0 to 5.0, heating, warming and stirring; adding manganese dioxide and thiocarbazide, reacting for 2 to 3h under the heat preservation condition, centrifuging and filtering, sending filtering residue into a freeze-drying machine, drying the solid, and crushing by a superfine crusher, so as to obtain a micropowder; (2) dissolving the micropowder and soluble metal salt, dispersing into an acetic acid water solution, and stirring to react, so as to obtain a precursor of the adsorption carrier; (3) impregnating the precursor of the adsorption carrier by the acid solution,so as to obtain the adsorption carrier. The adsorption carrier has the advantages that the metal is recycled from the waste lithium ion batteries in a targeted way; the adsorption carrier for the recycling of metal ions can be repeatedly utilized, so as to effectively reduce the recycling cost of the metal.

Owner:四会市恒星智能科技有限公司

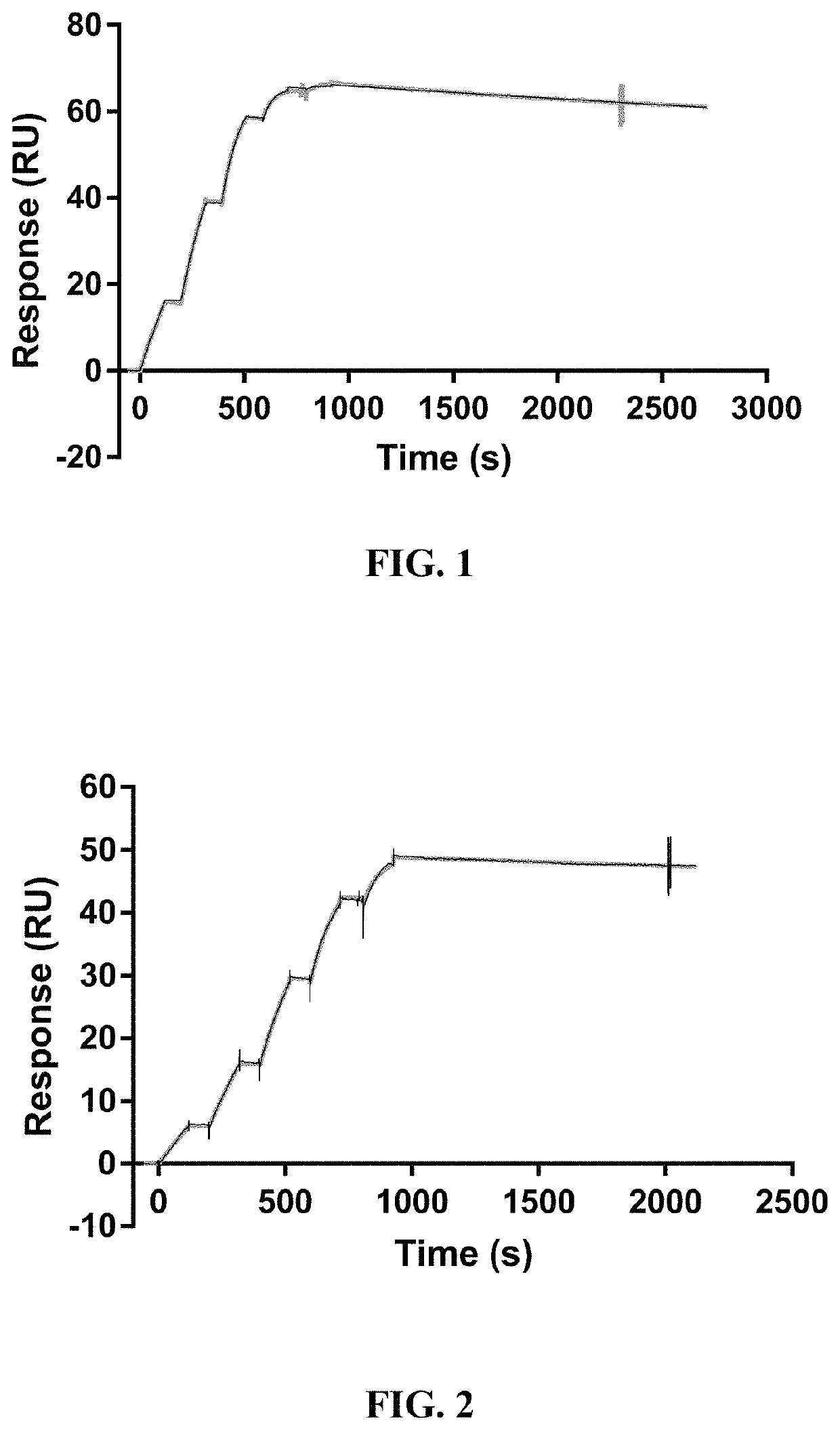

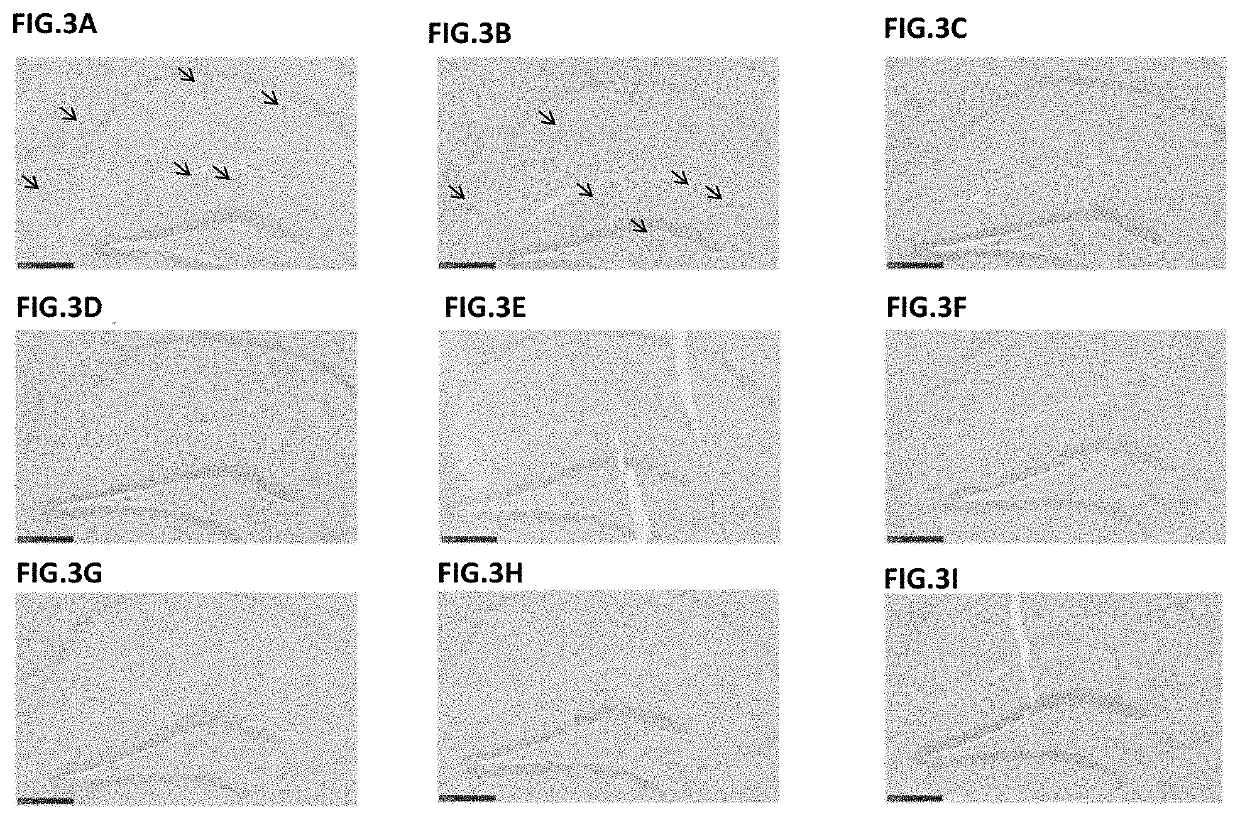

Antibodies to Pyroglutamate Amyloid-B and Uses Thereof

ActiveUS20180142011A1Nervous disorderMicrobiological testing/measurementAntigen Binding FragmentAmyloid beta

The invention provides an antibody or antigen binding fragments thereof that binds to 3pE Aβ and methods of making and using the antibody or antigen binding fragment thereof, including use for formulations, administration and kits. The antibody and antigen binding fragments thereof and methods disclosed are useful for diagnosis, prognosis and treatment of Alzheimer's disease or other β-amyloid-related diseases.

Owner:JANSSEN PHARMA NV

Novel amino acid-enriched water-soluble fertilizer

InactiveCN107793252APromote growthImprove qualityMagnesium fertilisersOrganic fertilisersMolybdic acidBorax

The invention discloses a novel amino acid-enriched water-soluble fertilizer. The novel amino acid-enriched water-soluble fertilizer is composed of raw materials including, by weight part, 15-25 partsof magnesium sulfate, 20-28 parts of potassium humate, 3-5 parts of borax, 2-4 parts of polyaspartic acid ester, 1-3 parts of molybdic acid, 4-8 parts of magnesium oxide, 5-15 parts of artemisa argyiand 40-60 parts of DL-pyroglutamic acid. The novel amino acid-enriched water-soluble fertilizer can extract water locally and be dissolved in the water rapidly and further can be sprayed onto crops in a watering mode; meanwhile, the novel amino acid-enriched water-soluble fertilizer can also serve as the base fertilizer of plants to stimulate growth of the plants, to meet various nutritional requirements on crop growth, improve the nutrition absorbing and utilizing rate and enhance the crop quality. Meanwhile, the novel amino acid-enriched water-soluble fertilizer can improve the insect-resistant, drought-resistant, freezing-resistant and depletion-resistant capability of the crops.

Owner:徐州沐阳生物科技发展有限公司

Antibodies to Pyroglutamate Amyloid-B and Uses Thereof

ActiveUS20200308261A1Nervous disorderImmunoglobulins against animals/humansDiseaseAntiendomysial antibodies

The invention provides antibodies or antigen binding fragments thereof that bind to 3pE Aβ and methods of making and using the antibodies or antigen binding fragments thereof, including use for formulations, administration and kits. The antibody and antigen binding fragments thereof and methods disclosed are useful for diagnosis, prognosis and treatment of Alzheimer's disease or other β-amyloid-related diseases.

Owner:JANSSEN PHARMA NV

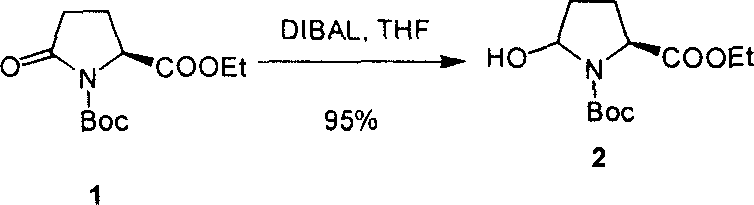

Preparation method of PF-06651600 intermediate

PendingCN112430208ALow priceLow costOrganic chemistry methodsBulk chemical productionBiochemical engineeringAnnulation

The invention relates to a preparation method of a PF-06651600 intermediate, and belongs to the field of medicinal chemistry. According to the method, Grignard ring-opened D-Boc-ethyl pyroglutamate isused as a raw material, a target compound is obtained through reduction, hydroxyl sulfonylation and cyclization, and the target compound can be further subjected to protecting group removal and salification. The method has the characteristics of novel structure intermediate compound, mild condition, easily available reagent, high product purity, high yield and safe operation, and can be used forindustrial production.

Owner:DONGGUAN HEC GENERIC DRUG R&D CO LTD +1

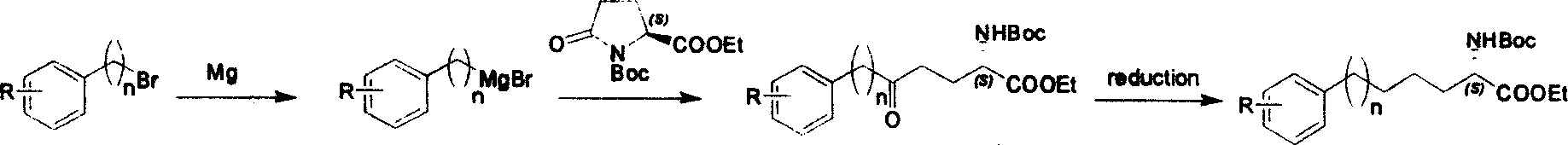

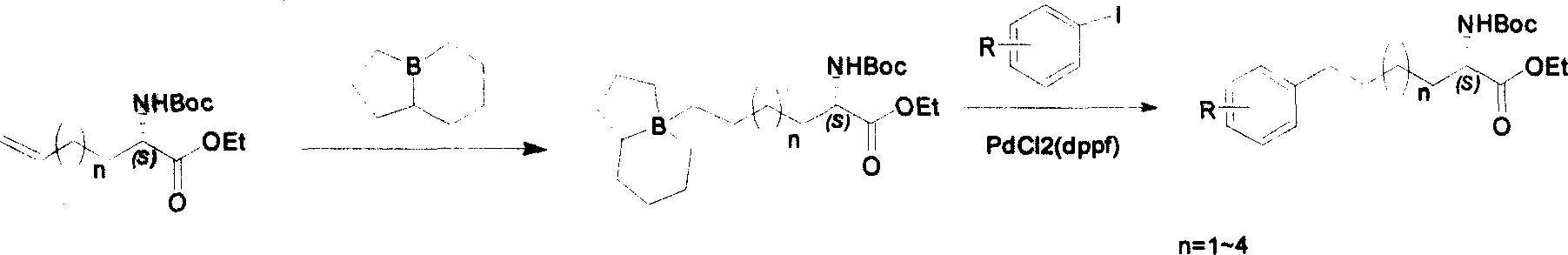

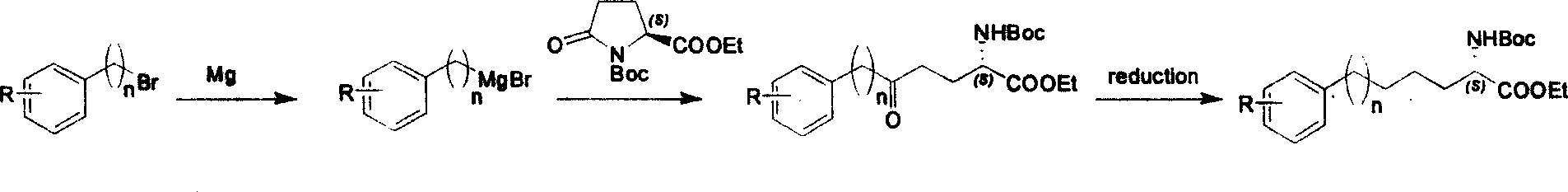

Method for synthesizing optically active derivative of omega - aryl ¿C (2S) ¿C N ¿C boc ¿Calpha amino acid

ActiveCN101092371AReduce usageReasonable choice of reaction processOrganic compound preparationAmino-carboxyl compound preparationArylGrignard reagent

This invention relates to a process for synthesizing optically active omega-aryl-(2S)-N-tert-butyloxycarbonyl-alpha-amino acid derivative, more specifically, omega-aryl-(2S)-N-tert-butyloxycarbonyl-alpha-amino acid ester. The process comprises: preparing omega-arylalkyl bromide into Grignard reagent, reacting with ethyl N-tert-butyloxycarbonyl-L-pyroglutamate to obtain omega-aryl-5-one-(S)-N-tert-butyloxycarbonyl-alpha-amino acid ethyl ester, and reducing to obtain omega-aryl-(2S)-N-tert-butyloxycarbonyl-alpha-amino acid ethyl ester. The process has such advantages as reasonable reaction process, abundant raw materials, short synthesis time, and no need for expensive enzyme reagents, and is suitable for mass production.

Owner:上海药明康德新药开发有限公司

Method for treating last monosodium glutamate mother liquor

The invention discloses a method for treating a last monosodium glutamate mother liquor, which comprises the steps: removing sulfate radicals in the last monosodium glutamate mother liquor containing sodium pyroglutamate impurities through barium salt first, then using ionic membrane caustic soda to hydrolyze to ensure that sodium pyroglutamate is unlinked and transformed into sodium glutamate, precipitating a large amount of flocculent colloid at the same time, then removing precipitated colloid protein, salt precipitations and the like through two plate-and-frame filtrations, sending filtrate into an inorganic membrane for microfiltration separation to further remove impurities such as solid protein to obtain clear permeate liquid, sending the permeate liquid into a nanofilration membrane separation system to remove impurities such as soluble colloid, protein, residual sugar and pigment to obtain high-quality feed liquid, and re-sending the feed liquid into a monosodium glutamate production cycle chain to produce monosodium glutamate. The method removes impurities such as sulfate, metallic ions (such as calcium, magnesium, iron and the like), colloid, protein, residual sugar and pigment in the last monosodium glutamate mother liquor, improves the quality of the hydrolysis of the last monosodium glutamate mother liquor, replaces acid hydrolysis, reduces the consumption of a decoloring agent and the discharge amount of wastewater, and ensures that the production cost is greatly reduced.

Owner:SHANDONG FUFENG FERMENTATION CO LTD

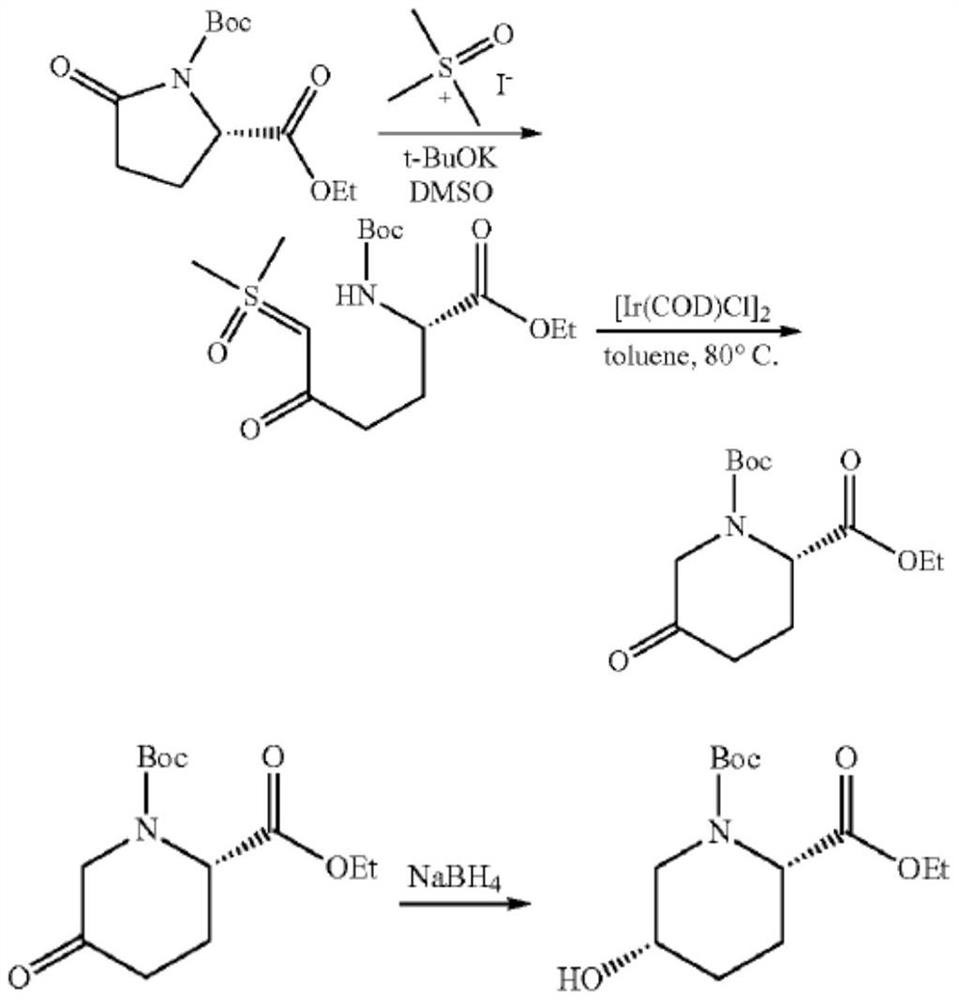

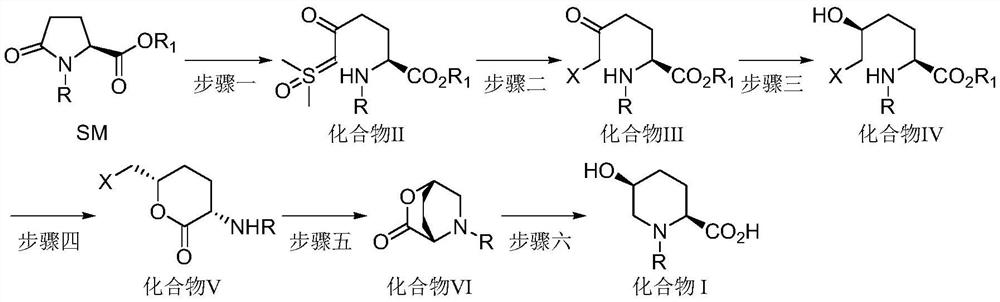

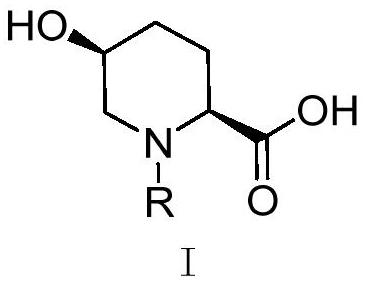

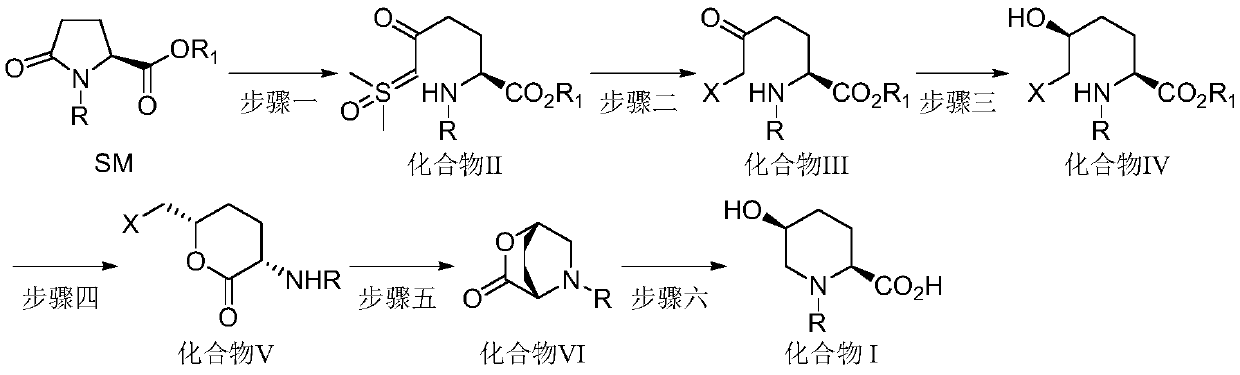

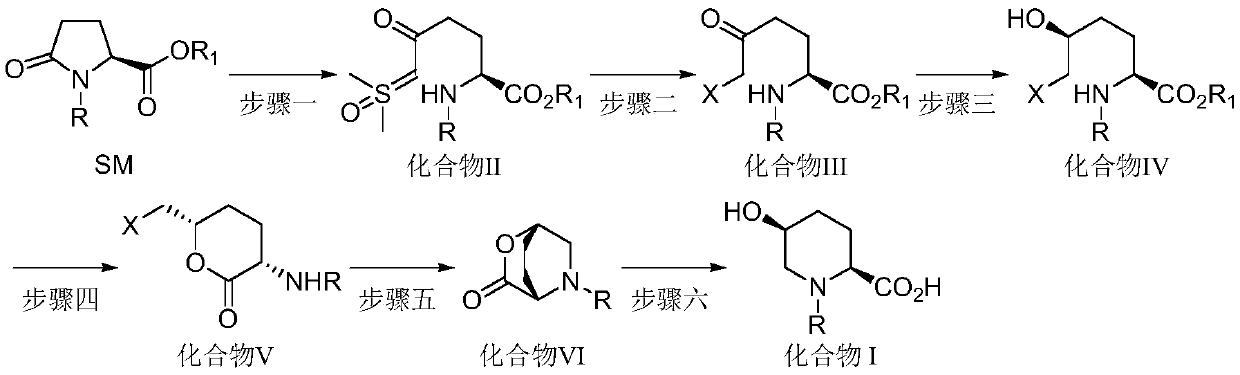

Synthetic method of avibactam intermediate (2S,5S)-N-protective group-5-hydroxy-2-piperidine formate

The invention discloses a synthetic method of an avibactam intermediate (2S,5S)-N-protective group-5-hydroxy-2-piperidine formate. N-protective group-L-pyroglutamate (SM) is taken as an initial raw material, and the (2S,5S)-N-protective group-5-hydroxy-2-piperidine formate is obtained through six steps of reactions including trimethyl sulfoxide iodide recarburization ring opening, halogenation under the action of acid, high-selectivity reduction, lactone ring formation under the catalysis of acid, piperidine ring closing under the action of alkali and hydrolysis. The synthetic method is mild in reaction conditions, simple and convenient to operate, easy in impurity control and stable in yield. The used reagents are low in price, the cost is effectively reduced, and the method is environment-friendly and suitable for industrial production.

Owner:山东安信制药有限公司

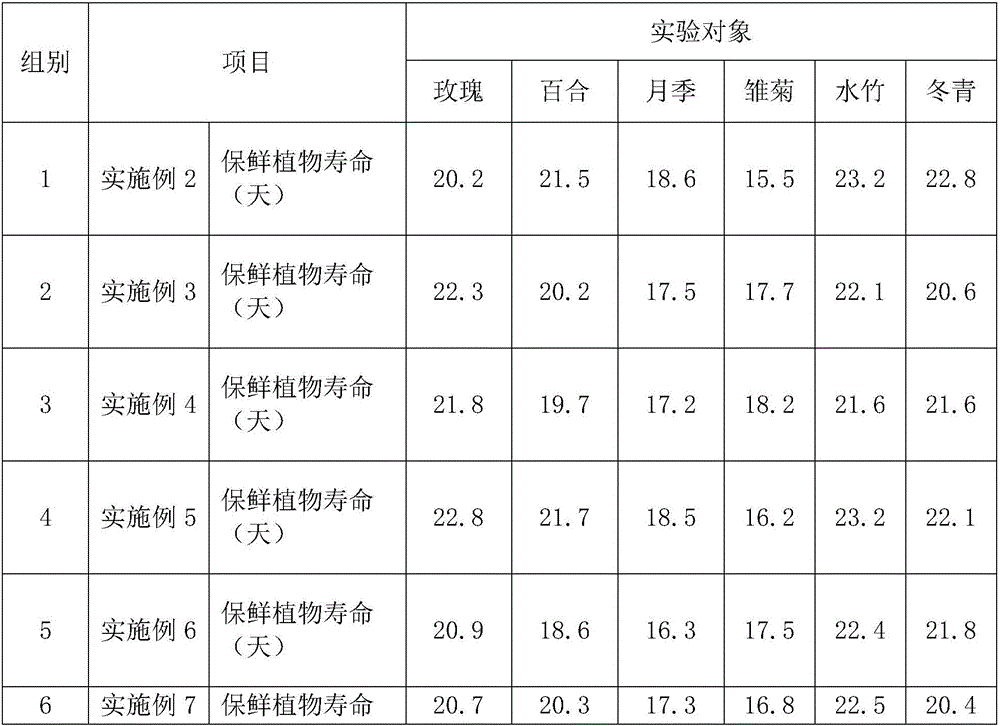

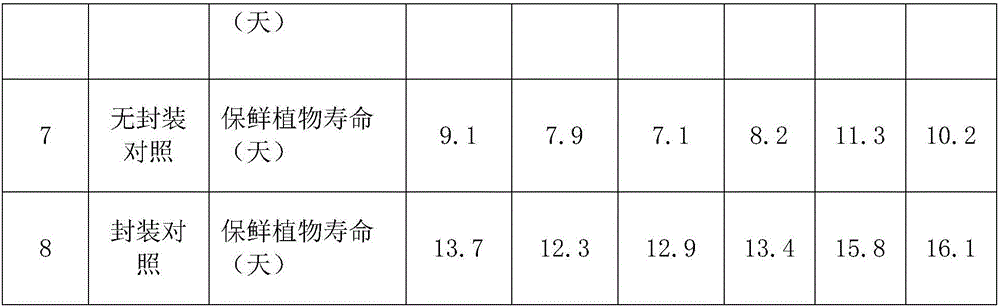

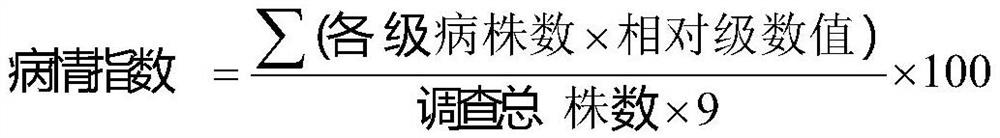

Preparation method of preservative for living plants

InactiveCN106417263ASimple preparation processReduce manufacturing costDead plant preservationDichlorvosKerosene

The invention belongs to the technical field of agricultural plant cultivation, and relates to a preparation method of a preservative for living plants. The preservative for living plants is mainly prepared from 1-5% of commercially available sodium L-pyroglutama, 2-4% of ethanol water solution with the weight percent concentration being 50%, 1-3% of garlic juice, 1-2% of fresh tobacco juice, 0.2-0.5% of dichlorvos, 0.1-0.2% of kerosene and the balance distilled water. The use method of the preservative for living plants includes the steps that the stem of a plant to be preserved is trimmed and retained by 10-25 cm, the redundant parts are cut away with an oblique cutting method, then the plant to be preserved is inserted into a vase containing the preservative with the level being 1 / 3 the height of the vase, the vase is put in an environment where the indoor temperature is 14-28 DEG C and the relative humidity is 50-70%, and finally flowers and leaves of the plant to be preserved are packaged with a pure transparent plastic film. The preparation method of the preservative for living plants is simple in process, the adopted raw materials are low in cost, environmentally friendly and easy to obtain, and the preservative for living plants is suitable for large-scale production and good in application environment and has broad market prospects.

Owner:刘孜斐 +1

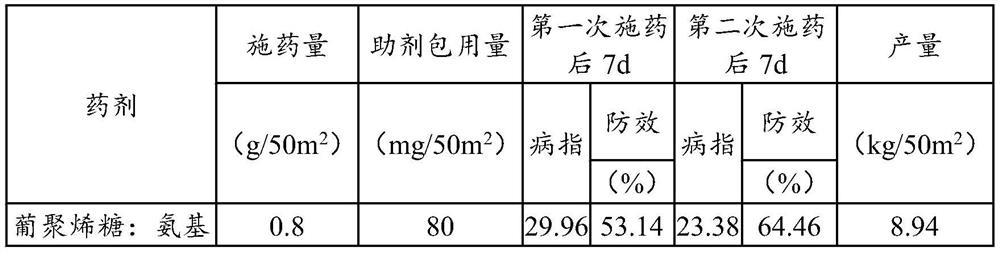

An agricultural composition comprising dextran

ActiveCN113040148BExcellent virus control effectIncrease productionBiocidePlant growth regulatorsBiotechnologyNicotiana tabacum

The invention discloses an agricultural composition containing dextran, which comprises effective components A and B, the A component is dextran, and the B component is amino oligosaccharin and chitosan , a kind of mushroom polysaccharide. The agricultural composition is used in combination with an auxiliary agent package, and the effective component of the auxiliary agent package is a compound of diosgenin and L-pyroglutamic acid. In terms of mass ratio, the diosgenin and L-pyroglutamic acid ‑The mass ratio of pyroglutamic acid is 3:2. Within a certain proportion range, the agricultural composition has excellent control effects on tobacco mosaic virus disease, tomato virus disease and cucumber mosaic virus disease, and can promote crop yield increase.

Owner:四川百事东旺生物科技有限公司

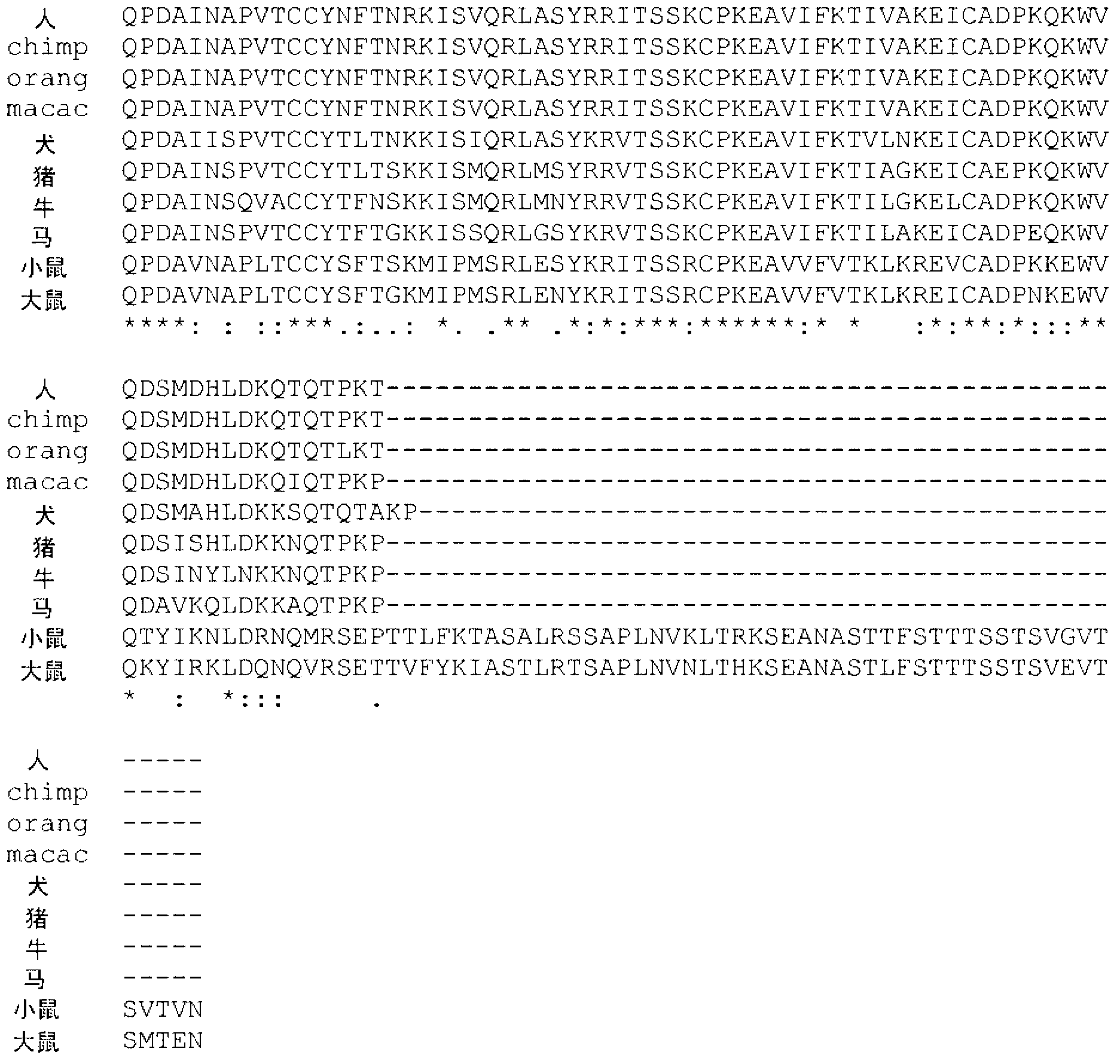

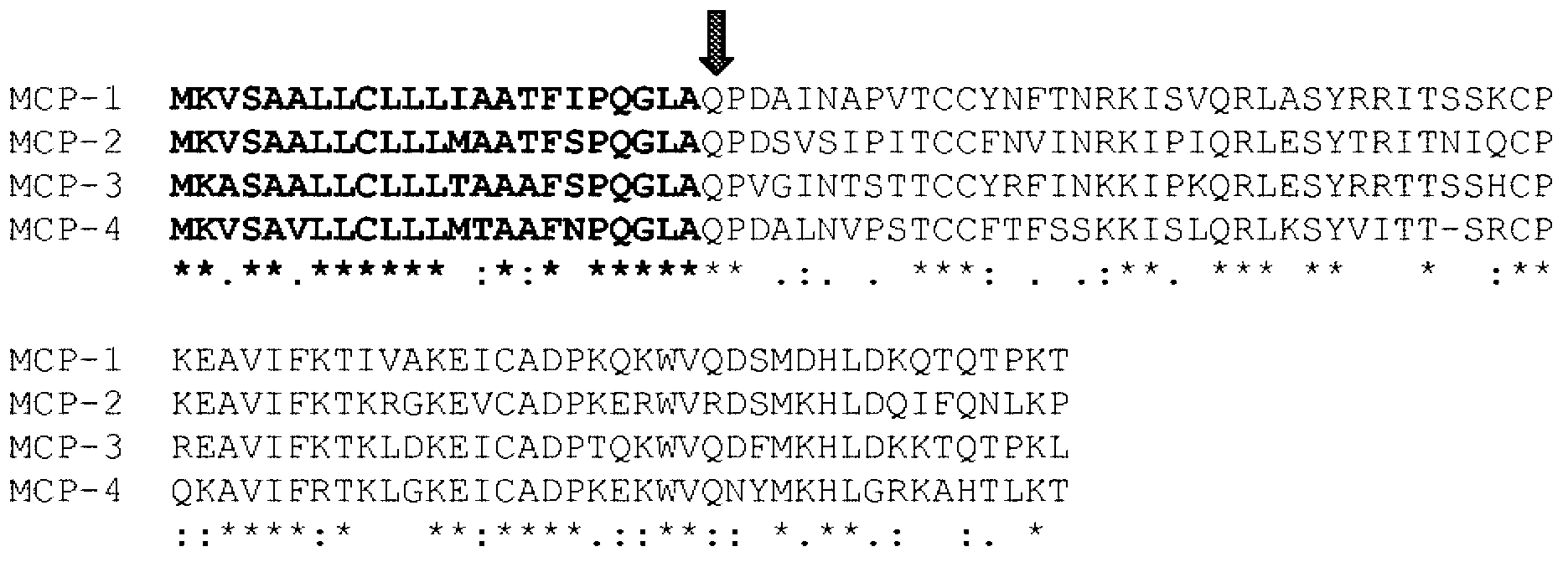

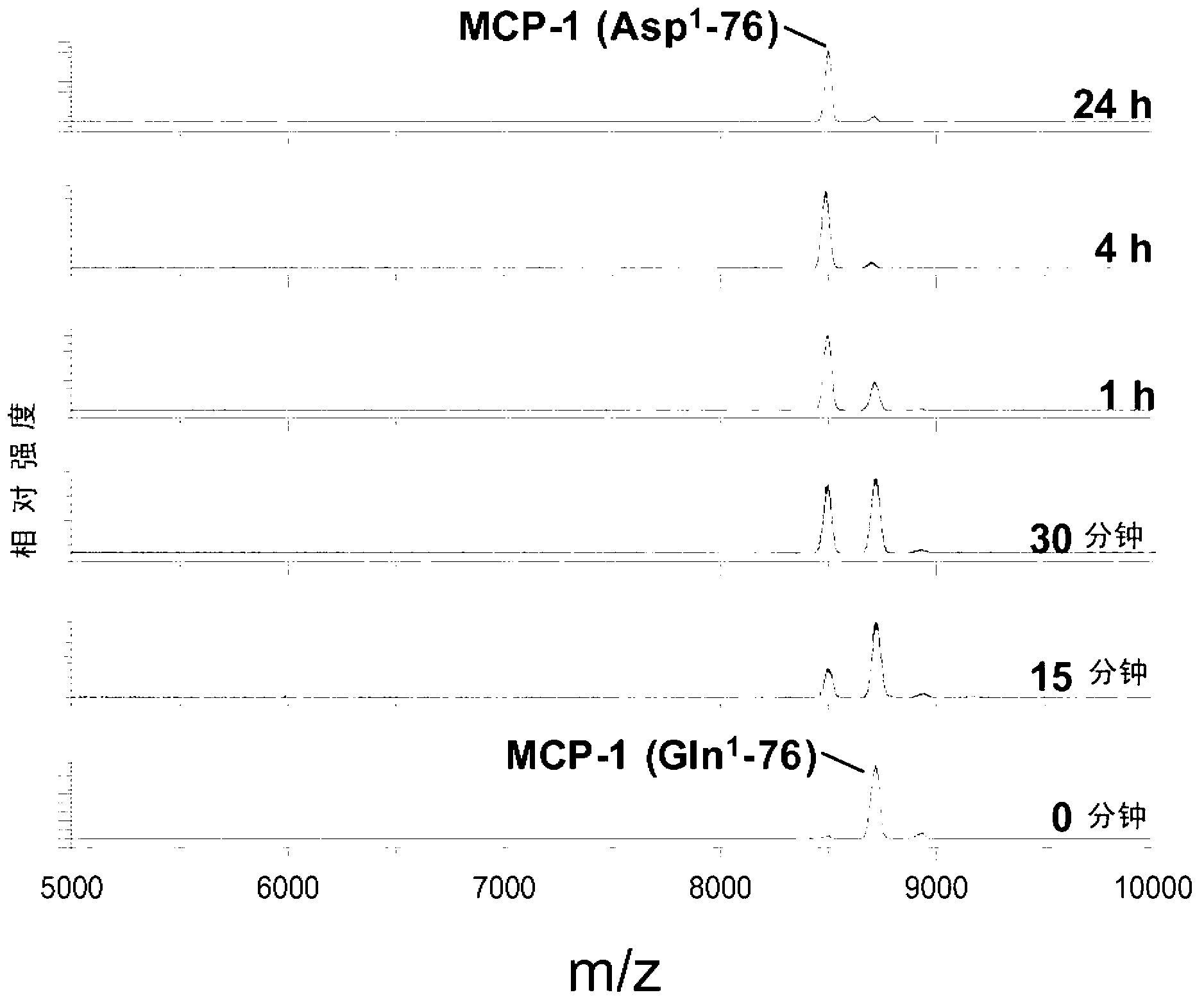

Methods of diagnosing inflammatory diseases by determining pyroglutamate-modified mcp-1 and screening methods for inhibitors of glutaminyl cyclase

InactiveCN102947705AIndustrial applicabilityDisease diagnosisBiological testingGlutethimideScreening method

The invention relates to a method to monitor treatment of an inflammatory disease or an inflammatory associated disease with the use of the ratio of N-terminal pyroglutamate modified MCP-1 (MCP-1 N1pE) : total concentration of MCP-1 within a biological sample as a biomarker and further concerns a novel method to determine the proportion of N-terminal pyroglutamate modified MCP-1 in relation to the total concentration of MCP-1 in biological samples. The invention also provides a diagnostic kit and a method for screening a glutaminyl cyclase (QC) inhibitor or measuring the effectiveness of a glutaminyl cyclase (QC) inhibitor.

Owner:VIVORYON THERAPEUTICS NV

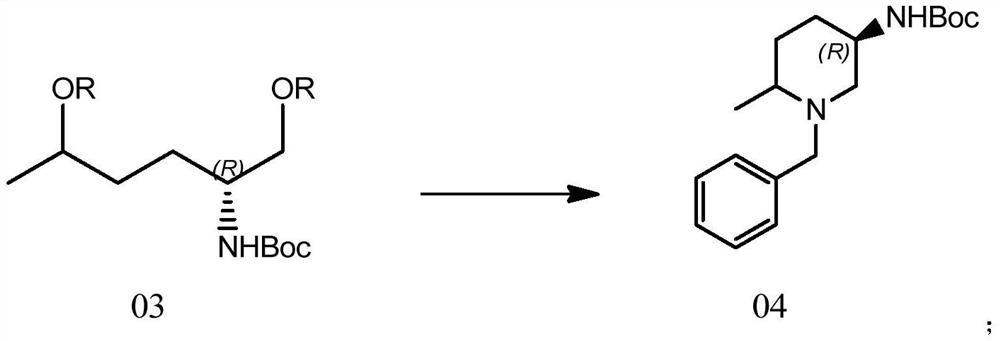

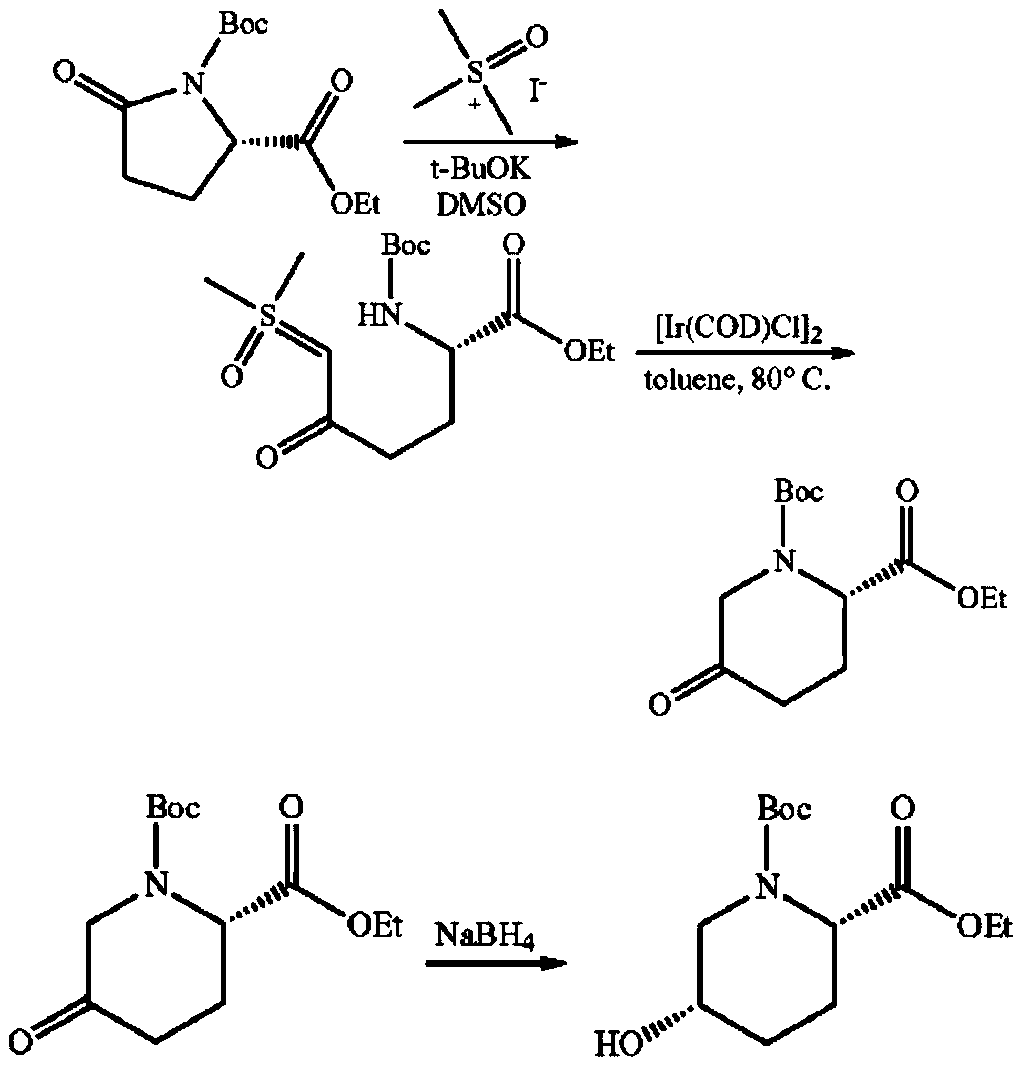

Preparation method of PF-06651600 intermediate

PendingCN112759535ACarbamic acid derivatives preparationOrganic compound preparationAnnulationCombinatorial chemistry

The invention relates to a preparation method of a PF-06651600 intermediate, and belongs to the field of medicinal chemistry. According to the method, D-Boc-ethyl pyroglutamate is used as a raw material, and a target compound 04 is obtained through Grignard ring opening, metal chiral reduction, hydroxyl sulfonylation and cyclization. According to the method, chiral column resolution or resolving agent resolution is avoided, reaction is mild, reagents are easy to obtain, the product purity is high, the yield is high, the operation is safe, column chromatography purification is avoided, and industrial production is facilitated.

Owner:SUNSHINE LAKE PHARM CO LTD

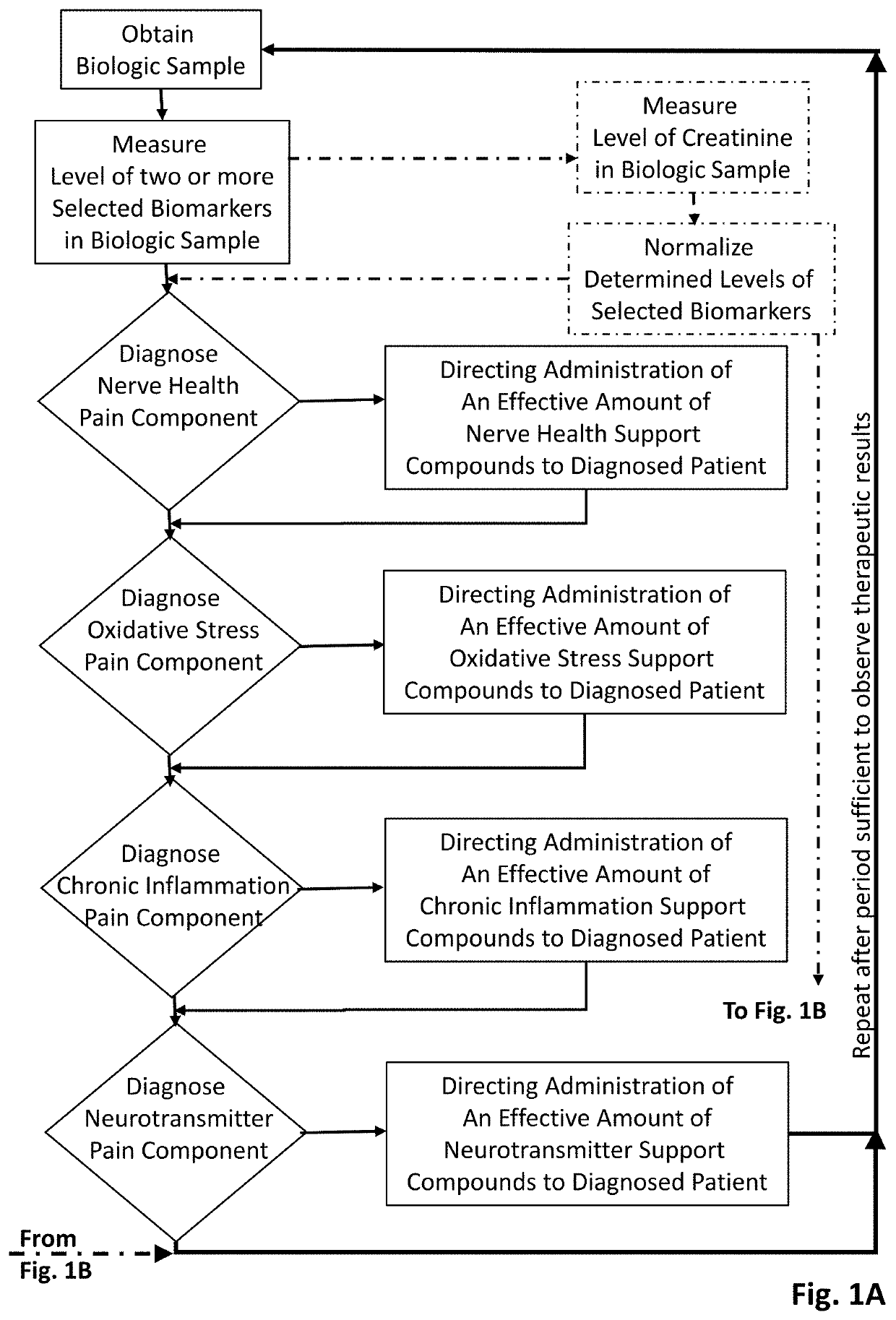

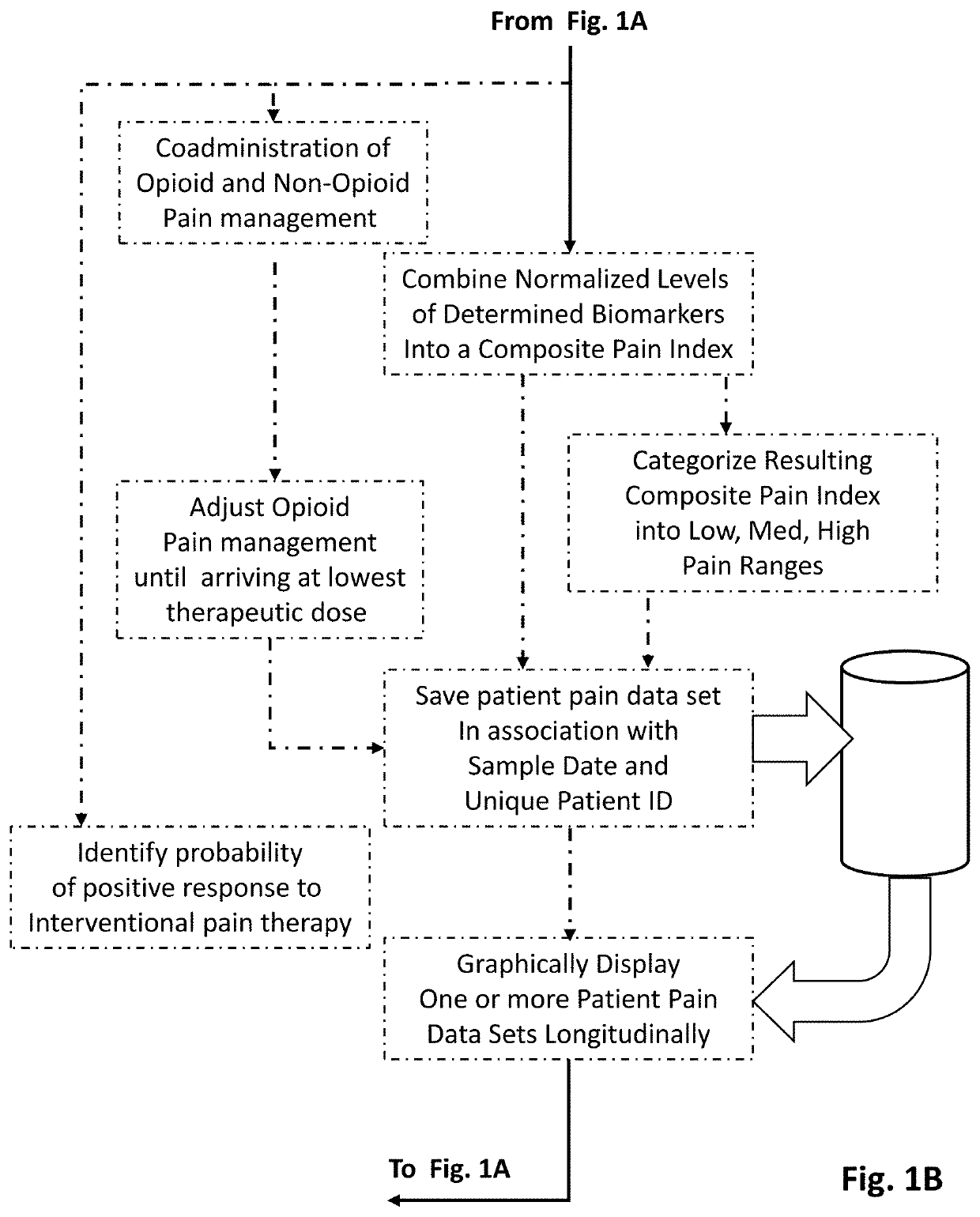

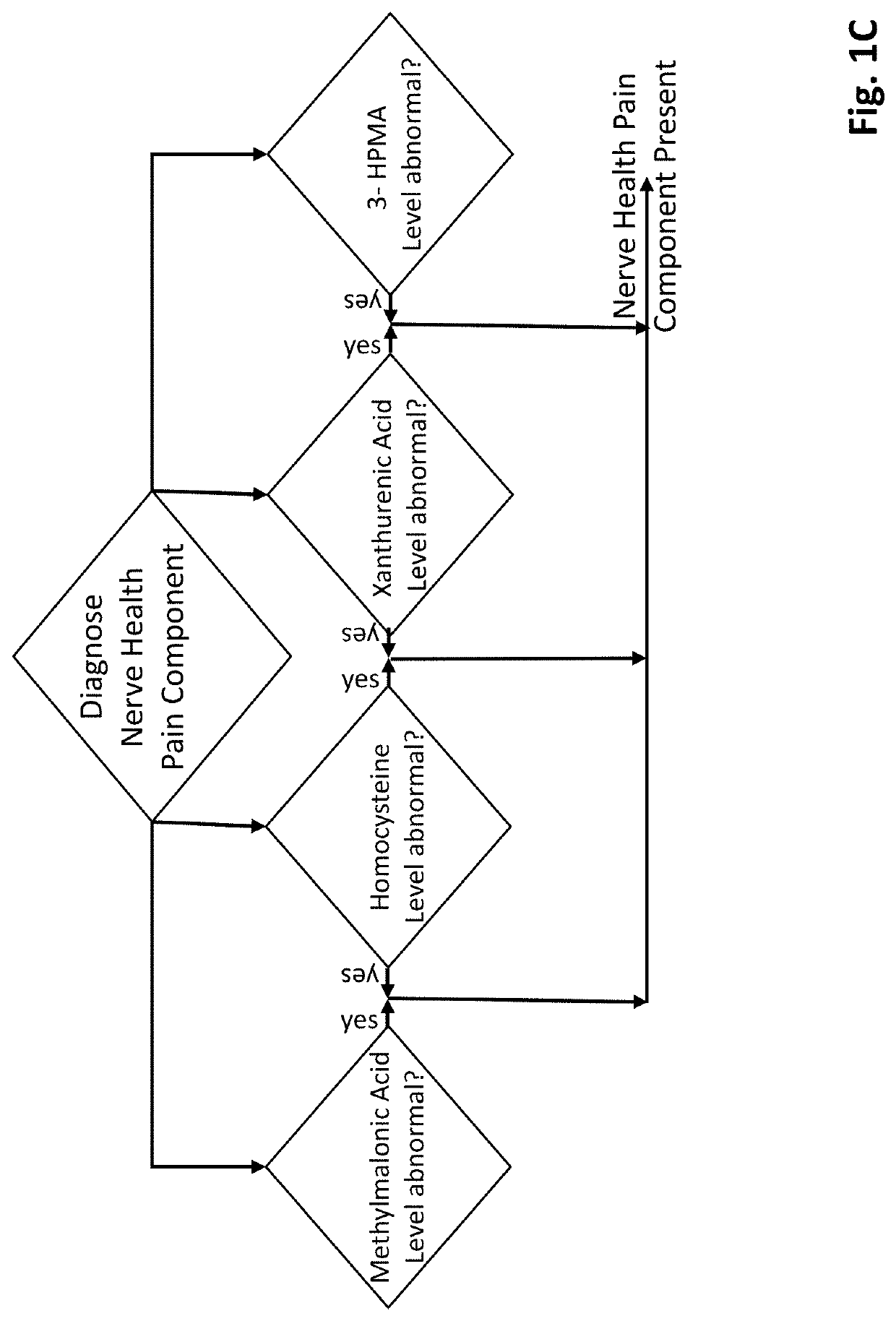

Methods of diagnosing and treating particular causal components of chronic pain in a patient

PendingUS20200363433A1Reduce chronic painEasy to manageOmicsDisease diagnosisOpioidergicEthylmalonic acid

The present disclosure teaches systems and methods of diagnosing and treating the distinct biologic components that contribute to chronic pain symptoms experienced by patients. A biologic sample is obtained from a patient. Levels of two or more biomarkers (e.g., methylmalonic acid, homocysteine, xanthurenic acid, 3-hydroxypropyl mercapturic acid (3-HPMA), pyroglutamate, hydroxymethylglutarate (HMG), quinolinic acid, kynurenine acid, 5-hydroxyindoleacetate (5-HIAA), vanilmandelate (VMA), and ethylmalonic acid) in the biologic sample are experimentally determined. Based on the existence of abnormal results in one or more biomarkers the patient is diagnosed as having the nerve health, oxidative stress, chronic inflammation pain, and / or neurotransmitter pain components to their chronic pain. Based on the resulting diagnoses administration of certain support compounds is directed. The patient may retest after a sufficient period of time to observe any longitudinal differences in the test results and adjust treatment accordingly. Further, the biomarker data gathered from pain-neutral and chronic pain patients (particularly those using opioid therapies) will be used to characterize biochemistries going forward.

Owner:ETHOS RES & DEV LLC

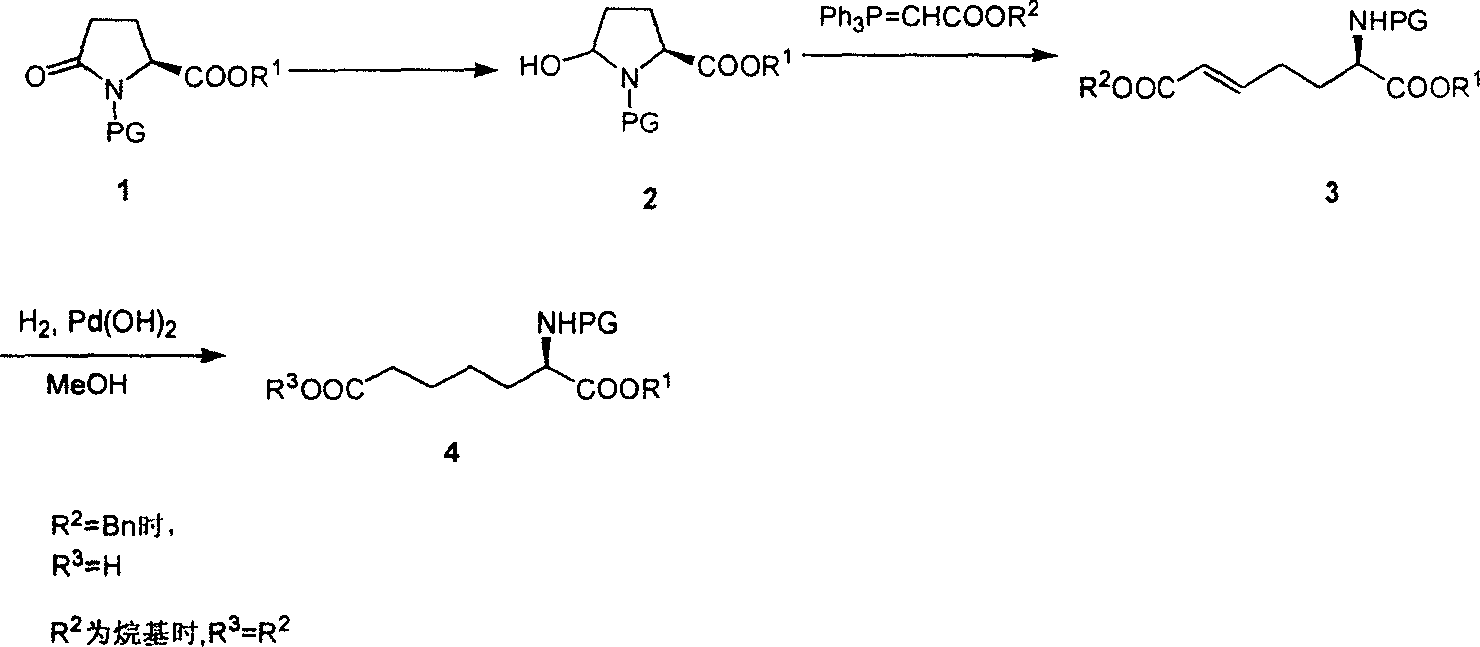

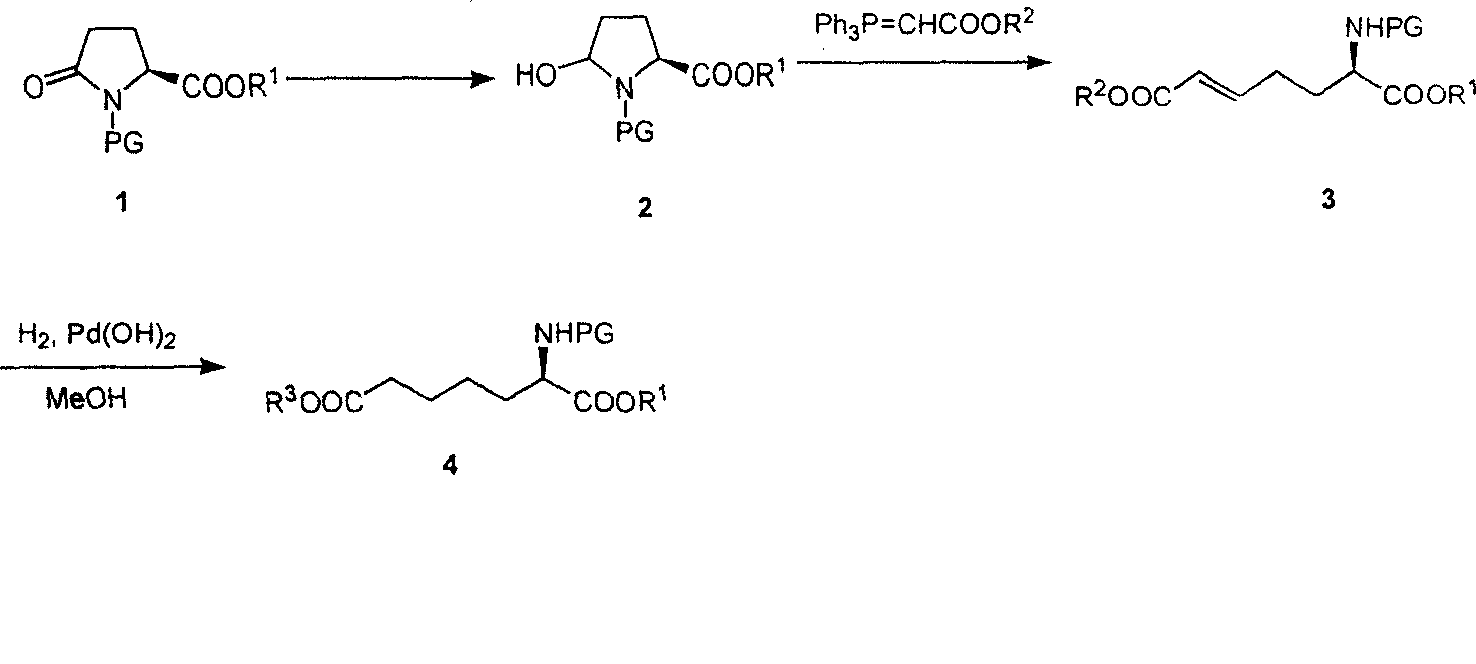

Method for practical synthesizing optically active alpha amino pimelic acid ester or monoester

ActiveCN101092372AHigh optical puritySimple processOrganic compound preparationAmino-carboxyl compound preparationWittig reactionL-Pyroglutamic Acid

This invention relates to a method for synthesizing optically active alpha-aminopimelic acid ester or monoester. The method comprises: reducing ethyl L-N-Boc-pyroglutamate to obtain hemiacetal, performing Wittig reaction to obtain corresponding olefin, and hydrogenating to obtain L-2-aminopimelic acid ester or L-2-aminopimelic acid monoester. The method has such advantages as simple synthesis rotine, reasonable process, high enantio selectivity, high optical purity of the product, and abundant raw material, and can be used for mass production of L-2-aminopimelic acid ester or L-2-aminopimelic acid monoester. The method solves the problems of long synthesis rotine, expensive reagents, low enantio selectivity, and unable mass production faced by the present synthesis process.

Owner:CHANGZHOU HEQUAN PHARMA CO LTD

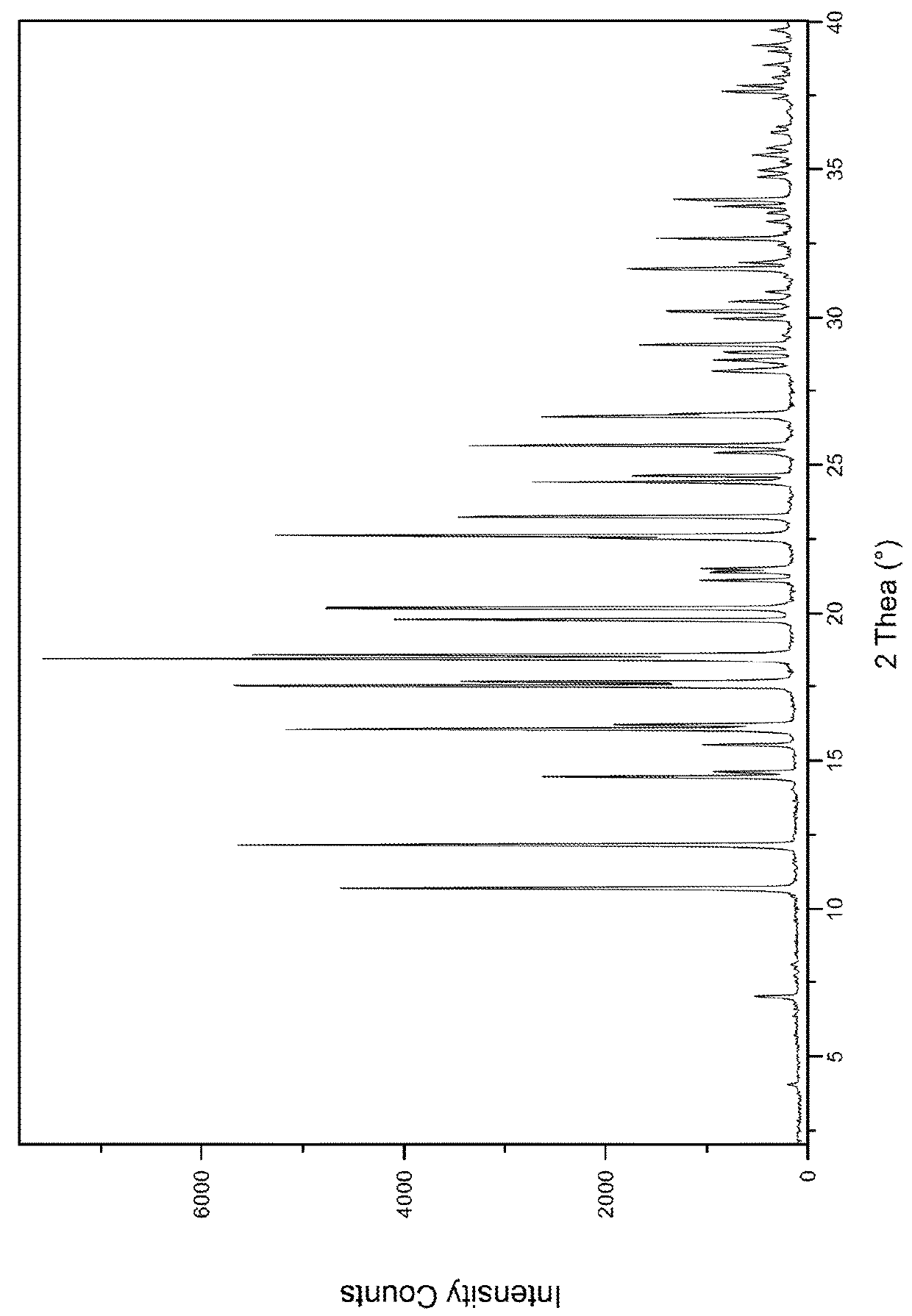

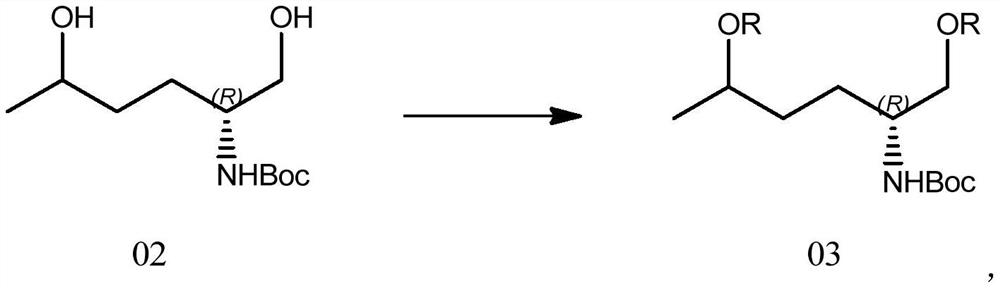

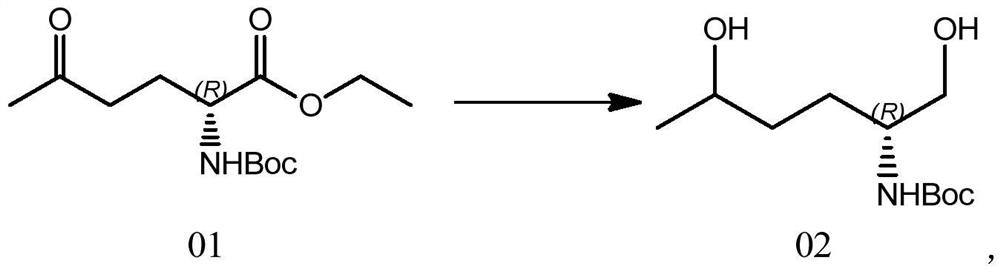

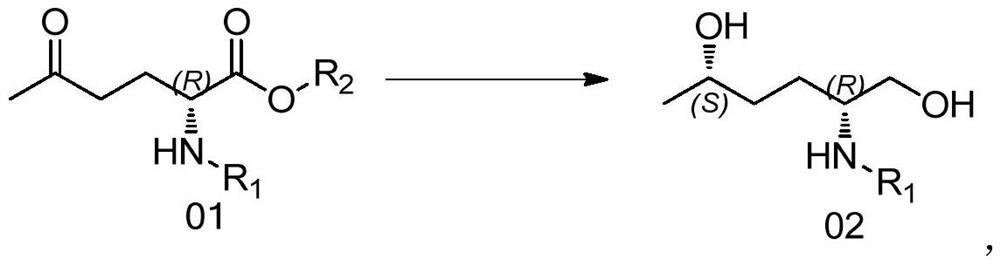

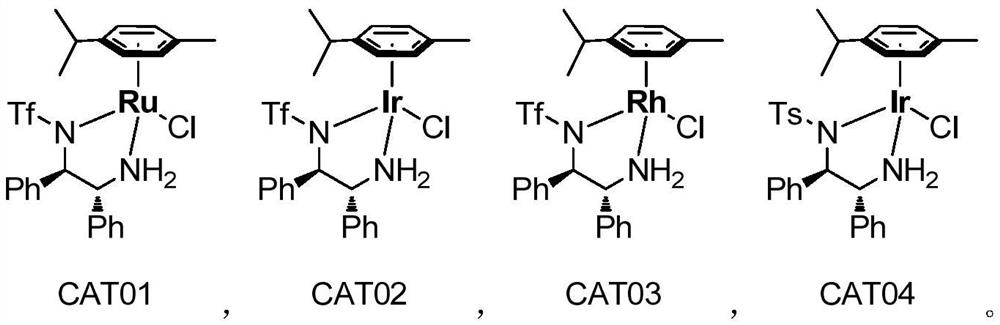

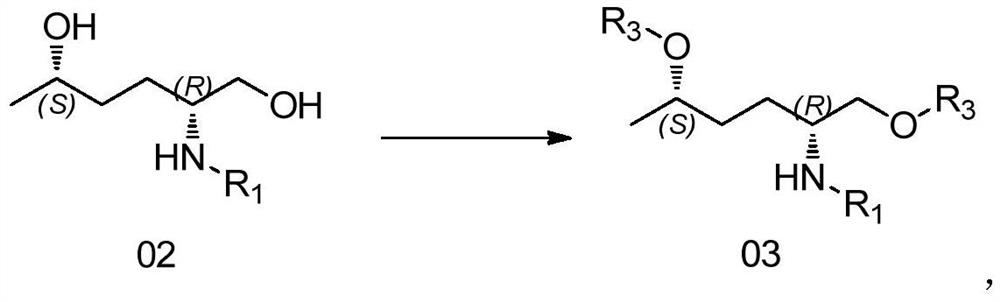

Method for synthesizing tert-butyl N-[(3R, 6R)-6-methylpiperidine-3-yl] carbamate by chemical enzyme method

PendingCN112877379AFew reaction stepsMild reaction conditionsOrganic chemistryFermentationEnzyme methodPyroglutamic acid

The invention relates to a method for synthesizing tert-butyl N-[(3R, 6R)-6-methylpiperidine-3-yl] carbamate by a chemical enzyme method, which comprises the following steps: S1, taking Boc-D-ethyl pyroglutamate as a substrate, and reacting with methyl magnesium halide at the temperature of -10- 0 DEG C to obtain an enzyme catalysis substrate; S2, adding an enzyme catalysis substrate into a potassium phosphate buffer solution containing an amino donor, then adding pyridoxal phosphate and transaminase, and carrying out spontaneous in-situ cyclization reaction to obtain lactam with double chiral centers; S3, lactam being subjected to a reduction reaction, and obtaining N-[(3R, 6R)-6-methylpiperidine-3-yl] tert-butyl carbamate. According to the method, Boc-D-ethyl pyroglutamate is taken as a raw material, so that the reaction steps are reduced, the reaction conditions are milder, an expensive metal catalyst and a high-pressure condition are not needed, the reaction process is safer, meanwhile, a complicated racemate resolution process is avoided, and the production cost is reduced.

Owner:SOUTH CHINA UNIV OF TECH

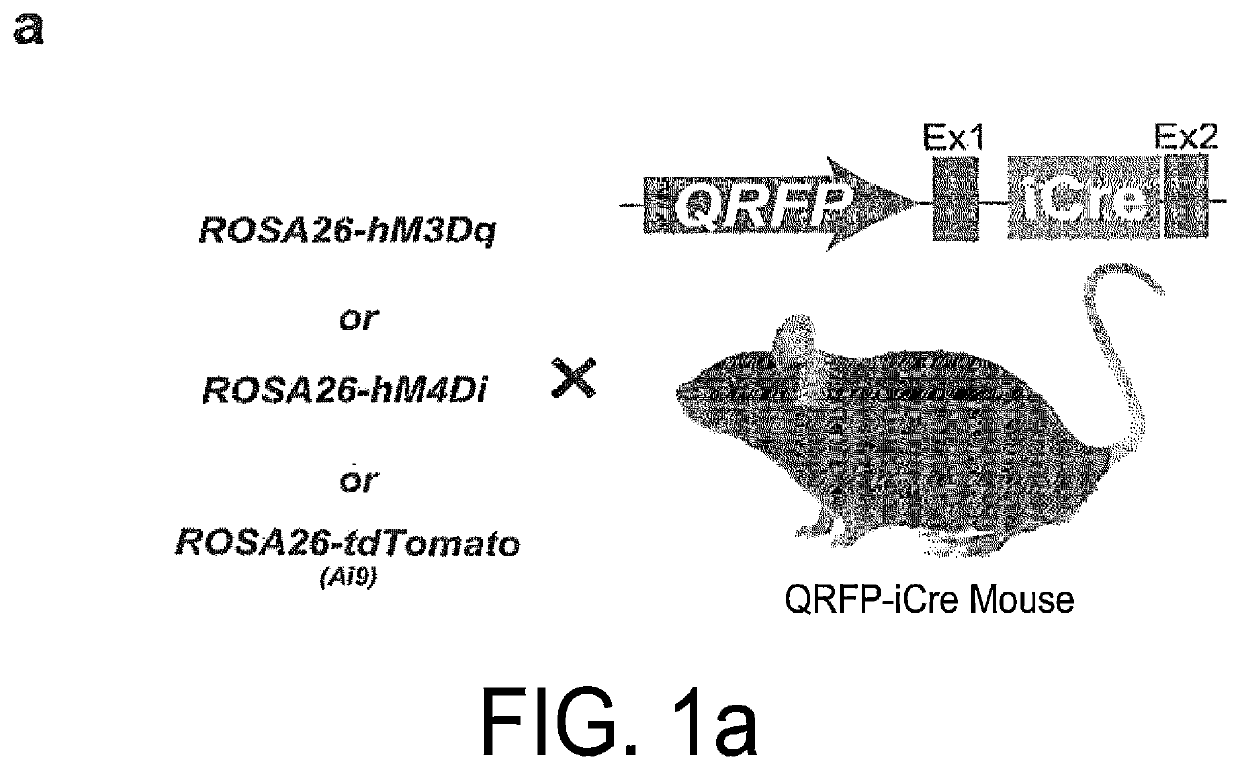

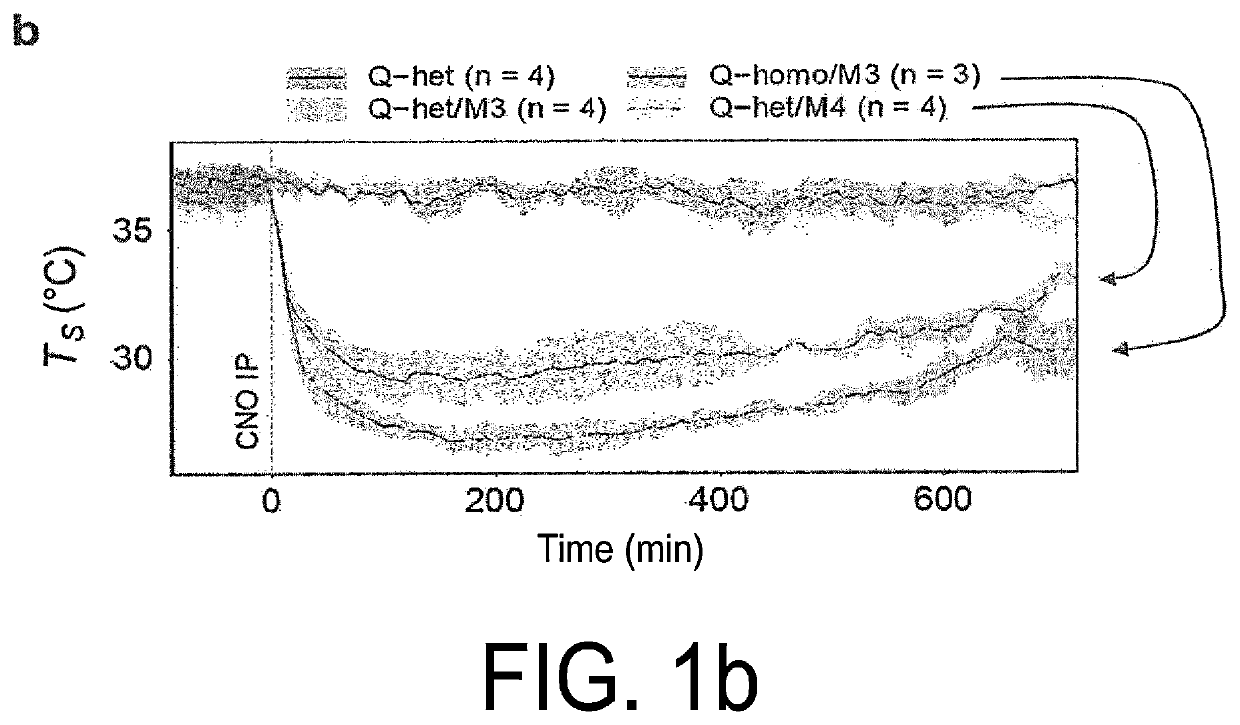

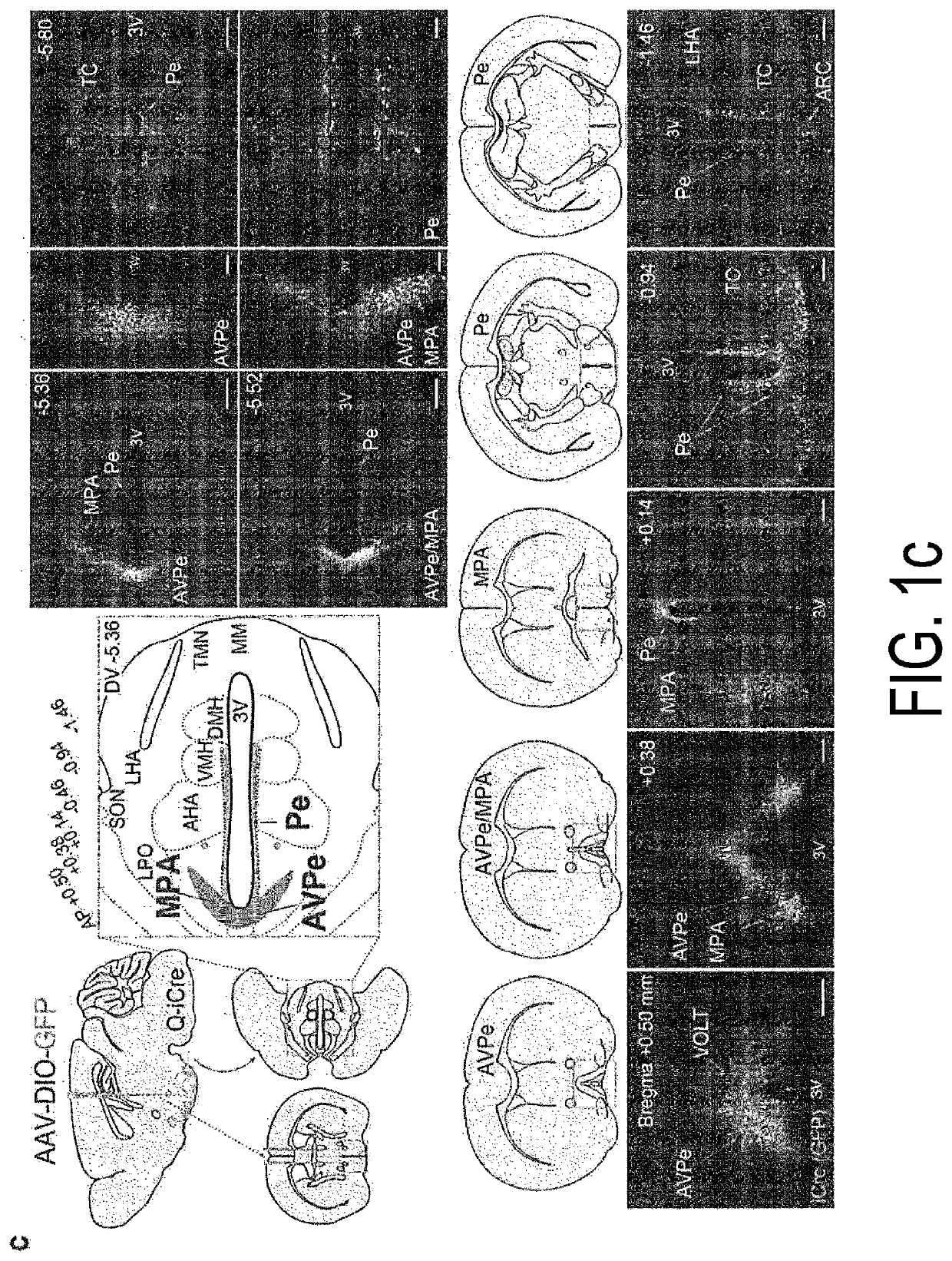

Method for inducing hibernation-like state and device same

A method for inducing a hibernation-like state and a device for the same is described. The method is a chemical and physical method for reducing, in a subject, a theoretical set-point temperature of a body temperature and / or a feedback gain of heat production, or for inducing a hibernation-like state in the subject, the method including applying an excitatory stimulus to pyroglutamylated RFamide peptide (QRFP)-producing neurons. A device used to implement the method is also described.

Owner:UNIV OF TSUKUBA +1

Polypeptides for the treatment of diseases

ActiveUS20200247850A1Therapy is simplePeptide/protein ingredientsPeptide preparation methodsDiseaseAcyl group

A polypeptide having the general amino acid sequence written in the single letter codeZ1IX2RWX5X6KX8PX10X11SZ3,whereinX2=V, M or L, in particular L,X5=S or T,X6=K or R, in particular R,X8=V, M, L or F, in particular M,X10=Q or C, in particular C,X11=V, M or F, in particular V;Z1=O, Z2, or pyro glutamate, wherein Z2= is a modification of the N-terminal nitrogen atom of the peptide chain which modification forms together with the amino group of the N-terminal amino acid of the peptide a moiety having the structure —NR2R3 wherein R2 and / or R3 are independently from each other H or a substituted or unsubstituted acyl, alkyl, aryl, aralkyl, cyclo alkyl and heterocyclo alkyl group;Z3=O, or Z4, whereinZ4= is a modification of the C-terminal carboxyl group of the peptide chain, which modification forms together with the carboxyl group of the C-terminal amino acid of the peptide a moiety having the structure —C(O)—O—R1 or —C(O)—NR2R3, wherein R1 is a substituted or unsubstituted alkyl, aryl, aralkyl, cyclo alkyl and heterocyclo alkyl group; and R2 and R3 are defined as above.

Owner:NEOPEP PHARMA GMBH & CO KG

Synthetic method of avibactam intermediate (2s, 5s)-n-protecting group-5-hydroxyl-2-carboxylic acid piperidine

Owner:山东安信制药有限公司

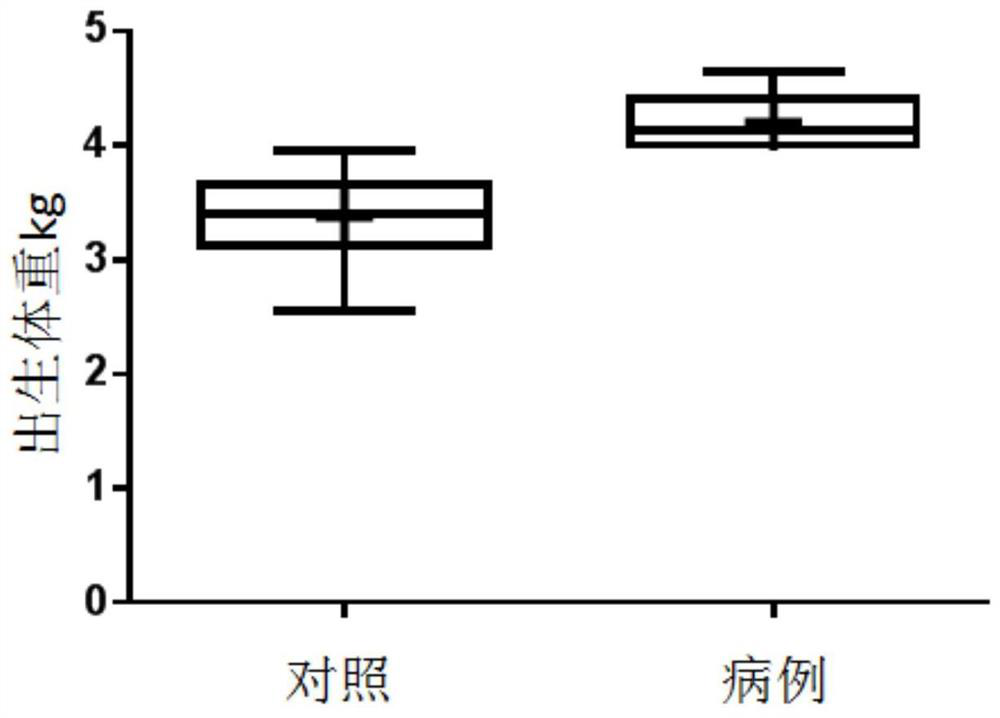

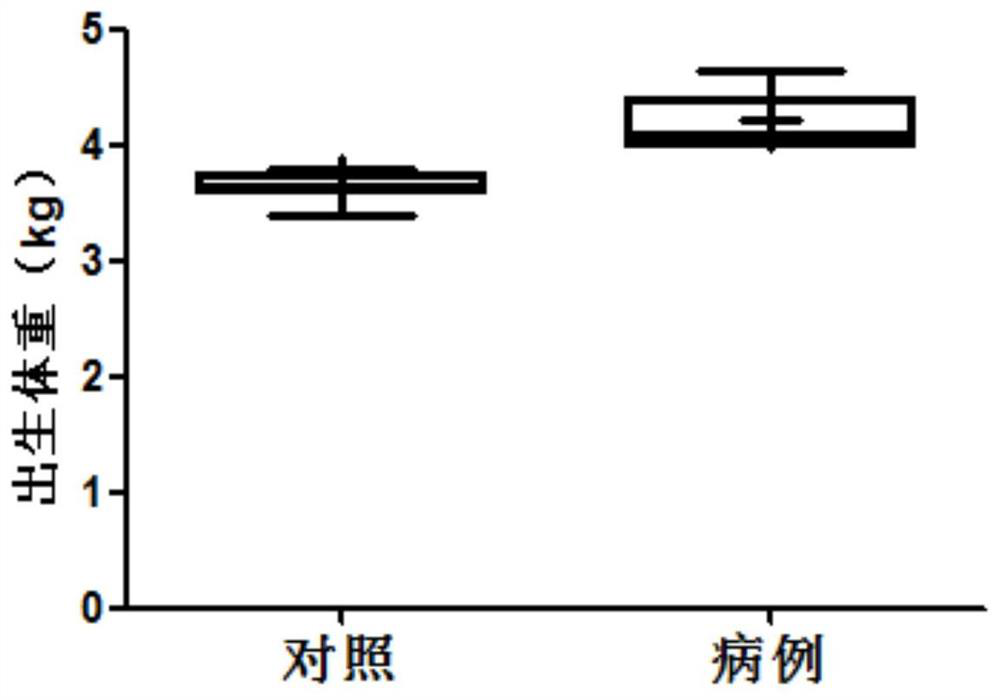

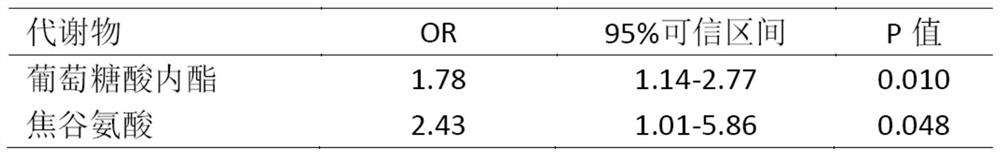

Gluconolactone and pyroglutamic acid as auxiliary diagnostic markers for macrosomia and their application

ActiveCN108872423BEasy diagnosisEasy to monitorComponent separationMass spectrometric analysisDiagnosis earlyAids diagnostics

The invention belongs to the field of analytical chemistry and clinical medicine, and discloses gluconolactone and pyroglutamic acid as auxiliary diagnostic markers for macrosomia and their application. The markers are small molecule gluconolactone and pyroglutamic acid in serum metabolism during pregnancy . The marker is detected by UPLC‑Q exact MS method, which has good sensitivity and specificity, can be used for early diagnosis or monitoring of macrosomia, and has good clinical application and promotion value.

Owner:NANJING MEDICAL UNIV

Polypeptides for the treatment of diseases

ActiveUS11124540B2Therapy is simplePeptide/protein ingredientsPeptide preparation methodsDiseaseAryl

Owner:NEOPEP PHARMA GMBH & CO KG

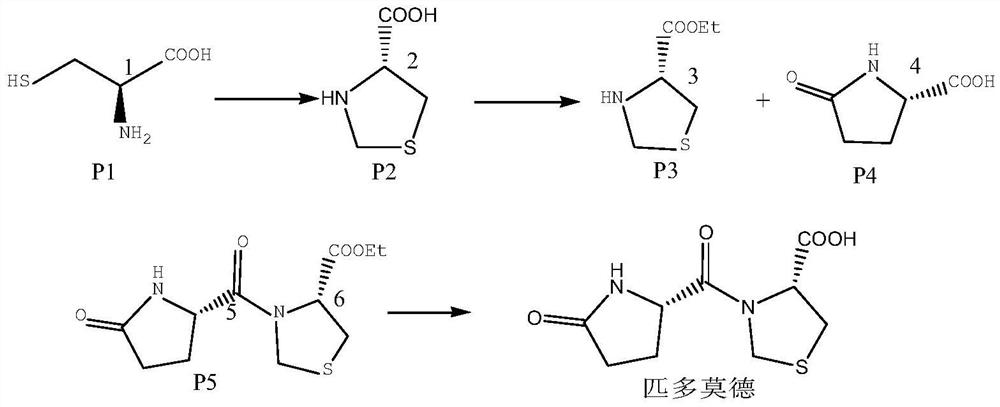

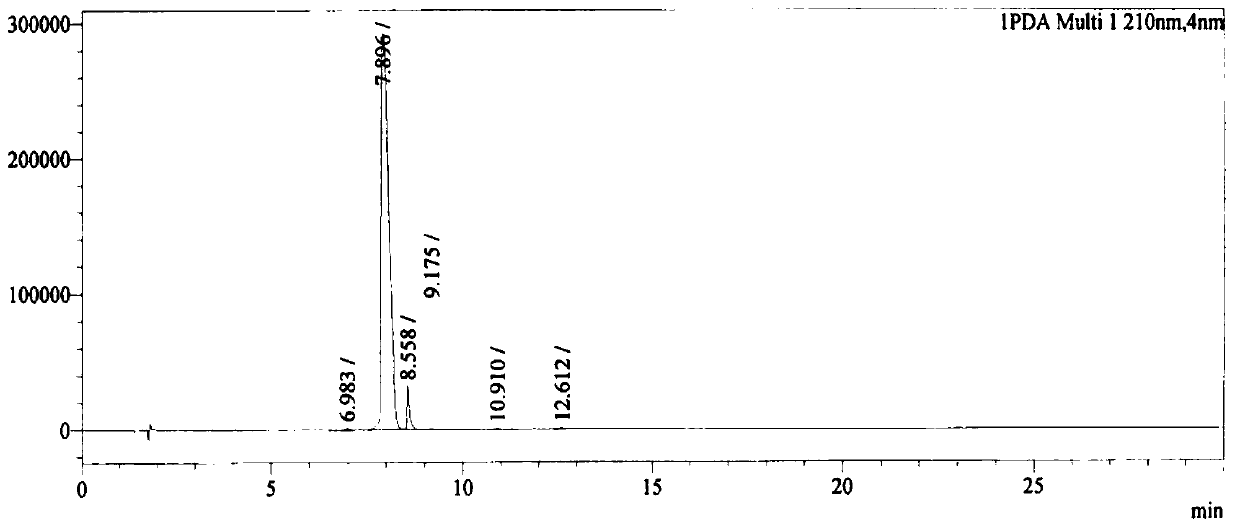

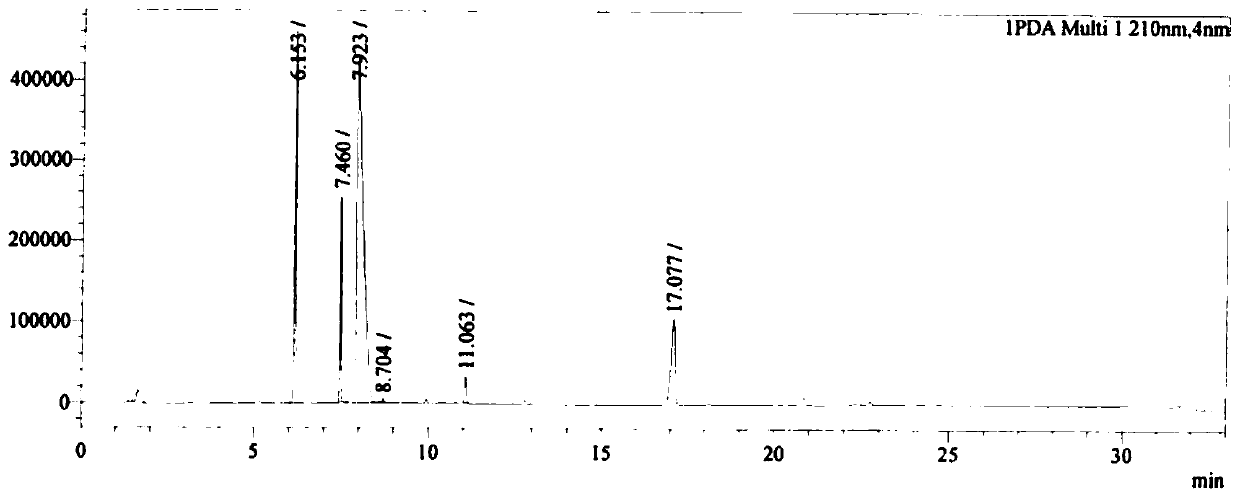

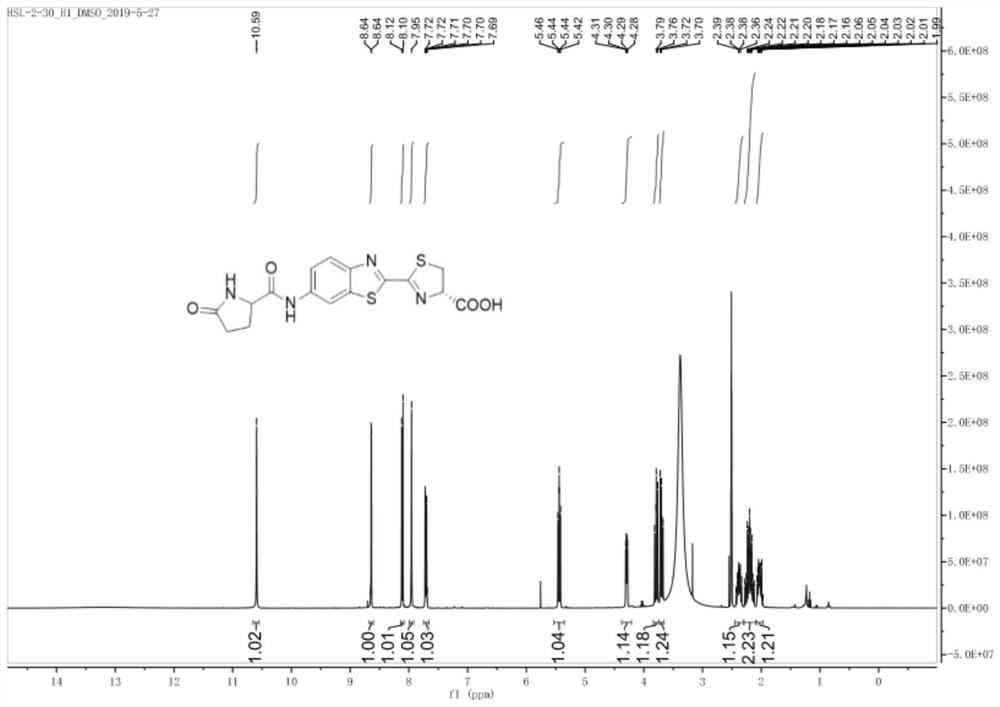

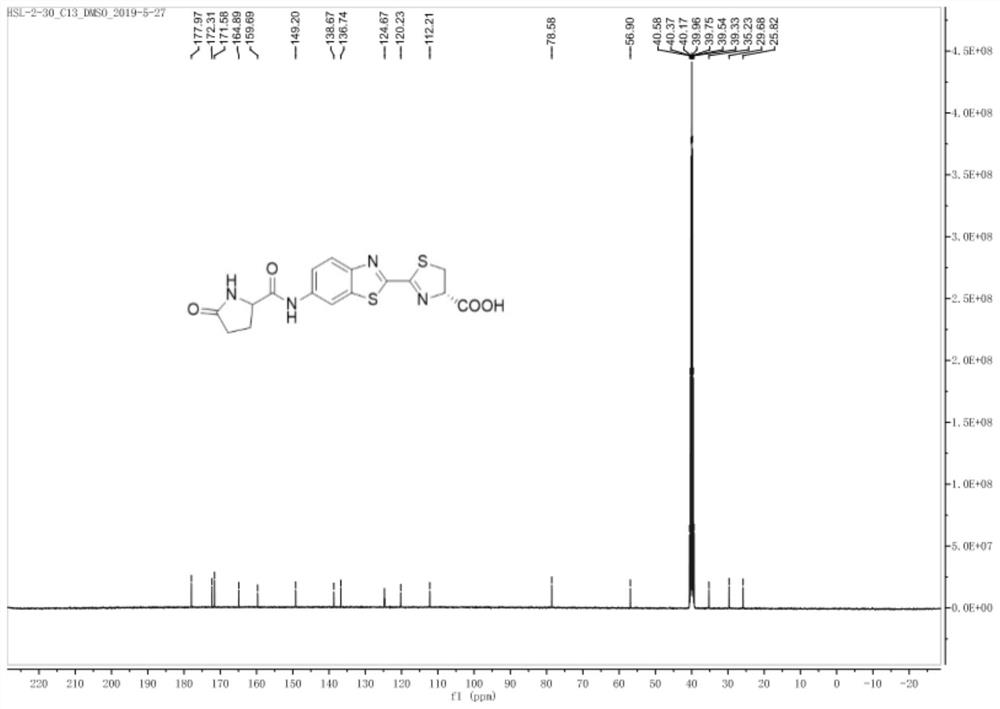

Synthesis and purification process of high chiral purity pidotimod

ActiveCN108530516BEfficient cultivationBreeding time is slowPeptide preparation methodsThio-Combinatorial chemistry

Owner:BEIJING JINCHENG TAIER PHARMA CO LTD

A kind of synthetic method of avibactam intermediate

ActiveCN108822014BLow priceReduce processing costsOrganic chemistryBulk chemical productionChemical synthesisMethyl palmoxirate

The invention discloses a synthesis method of an Avibactam intermediate, and belongs to the technical field of the medicine chemical synthesis. The synthesis method comprises the following steps: reacting pyroglutamate containing an amino protecting group with trimethylsulfoxonium iodide in a reaction solvent under the effect of the carbonate to obtain the Avibactam intermediate. The problems thata strong alkali process method in the prior art is large in potential safety hazard, relatively difficult in process control and high in impurity content are avoided, and the synthesis method disclosed by the invention is mild in reaction condition, simple in operation, high in process operability security, high in yield, high in product purity and suitable for the industrial production.

Owner:ZHUHAI UNITED LAB

Antibodies to pyroglutamate amyloid-β and uses thereof

ActiveUS11236155B2Nervous disorderImmunoglobulins against animals/humansDiseaseAntiendomysial antibodies

The invention provides antibodies or antigen binding fragments thereof that bind to 3pE Aβ and methods of making and using the antibodies or antigen binding fragments thereof, including use for formulations, administration and kits. The antibody and antigen binding fragments thereof and methods disclosed are useful for diagnosis, prognosis and treatment of Alzheimer's disease or other β-amyloid-related diseases.

Owner:JANSSEN PHARMA NV

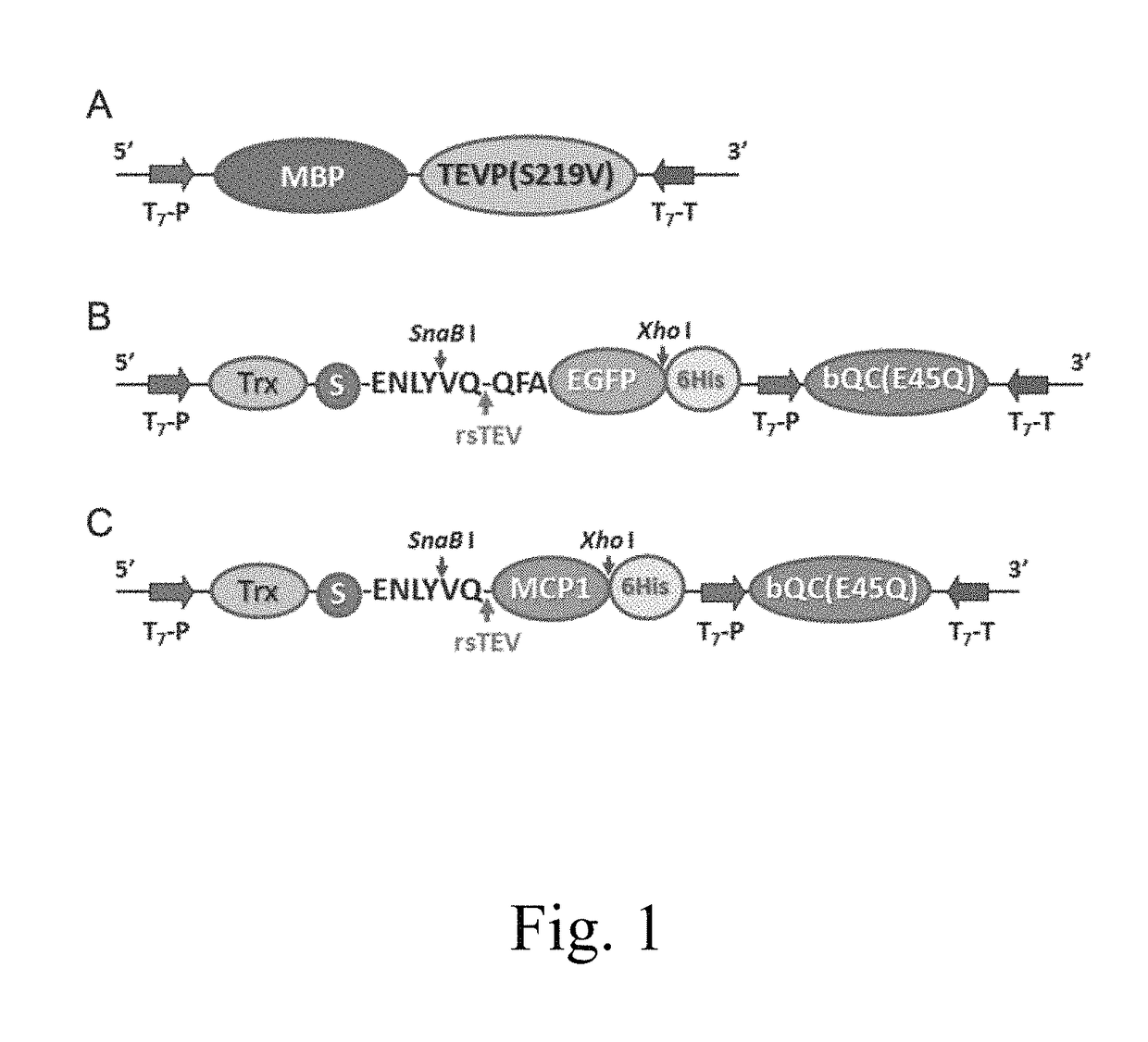

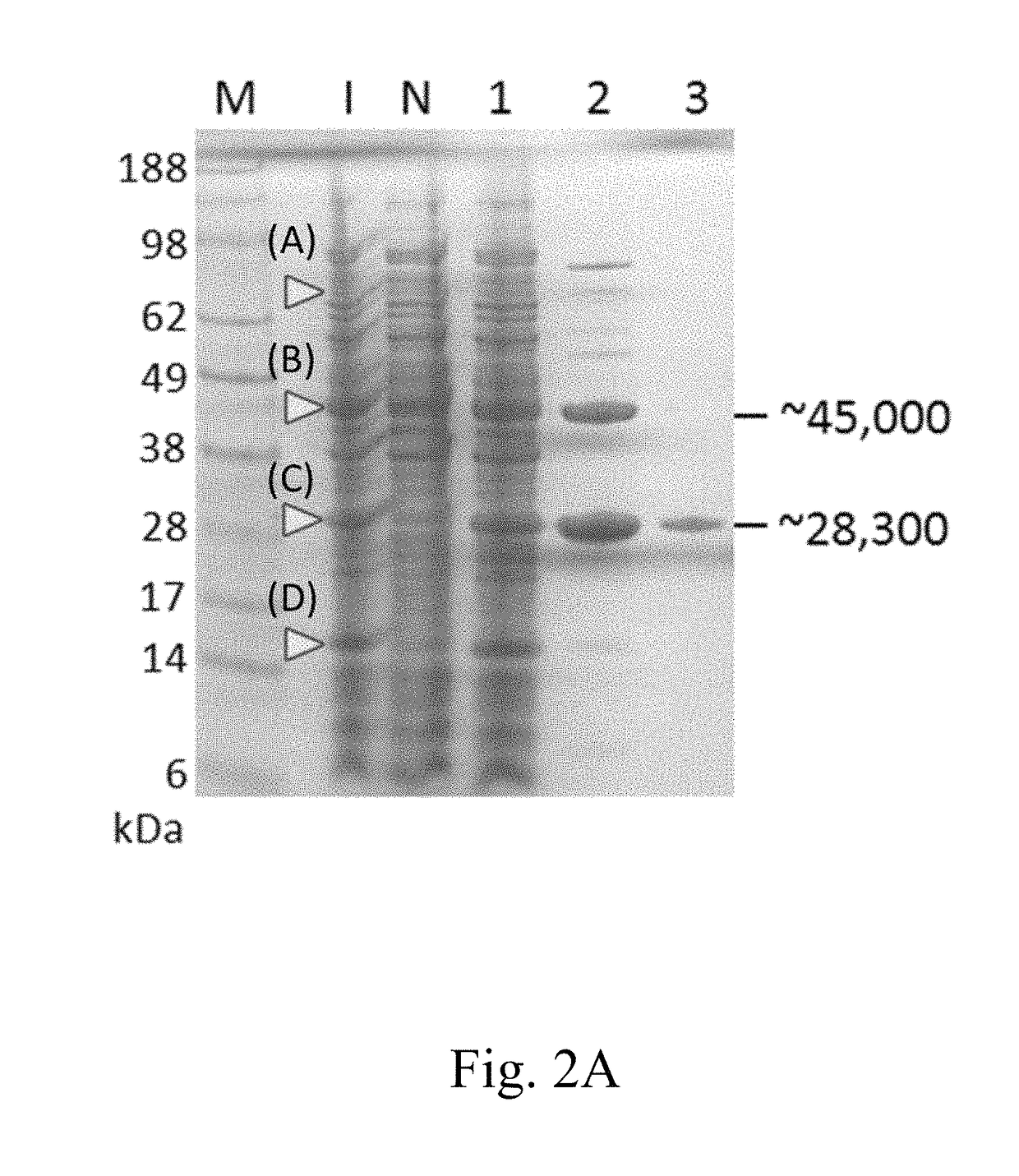

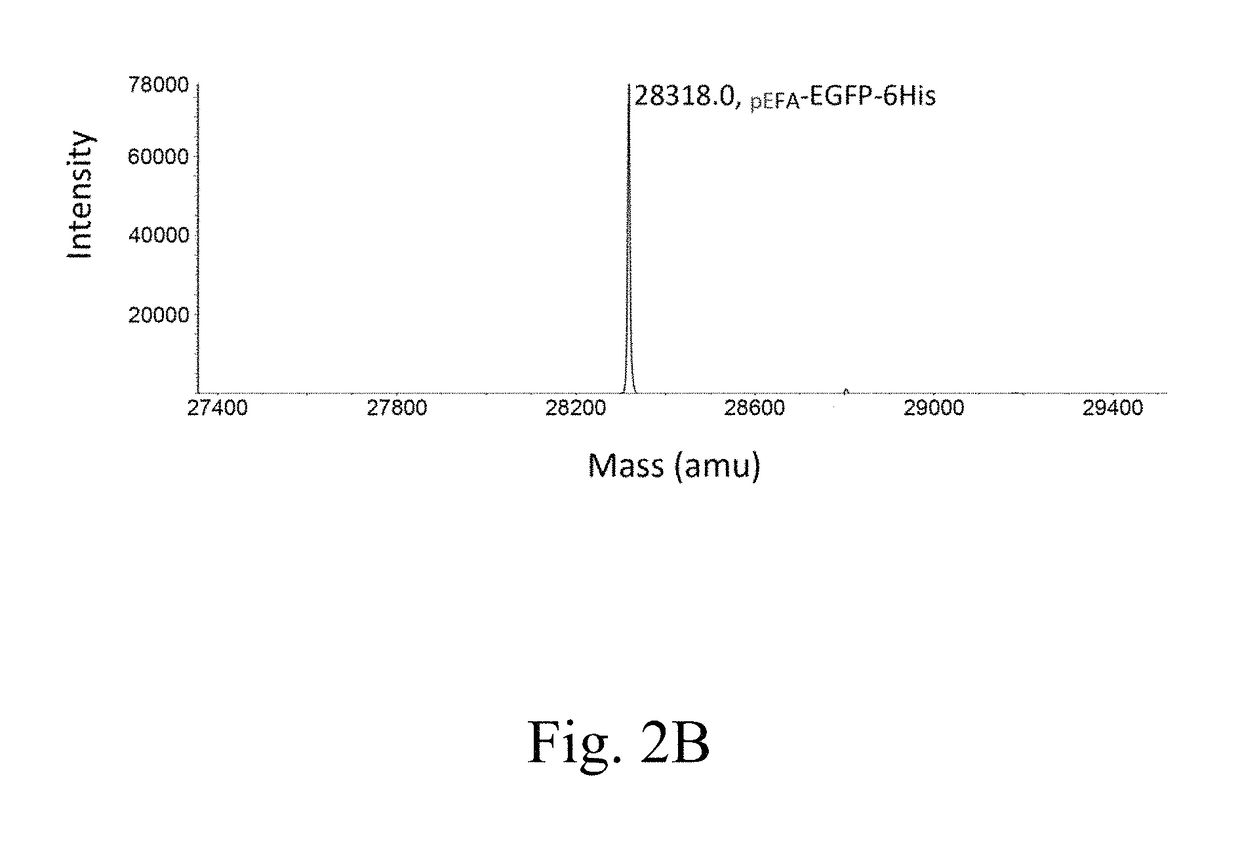

Expression system for producing protein having a N-terminal pyroglutamate residue

ActiveUS9856483B2AcyltransferasesCytokines/lymphokines/interferonsFusion Protein ExpressionNicotiana tabacum

Disclosed herein is an expression system and uses thereof. The expression system comprises two vectors that express two fusion proteins and a glutaminyl cyclase (QC) with E45Q mutation, so as to autonomously produce a target protein having a N-terminal pyroglutamate (pGlu) residue in a host cell. The first fusion protein is composed of a maltose binding protein (MBP) and a tobacco etch virus protease (TEVP); and the second fusion protein includes in sequence, a thioredoxin, a S-tag, a linker having a TEVP recognition site therein, a target protein, and a (His)-6-tag. The second fusion protein is cleaved by the TEVP that is expressed by the first fusion protein, and then catalyzed by QC with E45Q mutation so as to autonomously produce the target protein having a N-terminal pGlu residue in the host cell.

Owner:ACAD SINIC

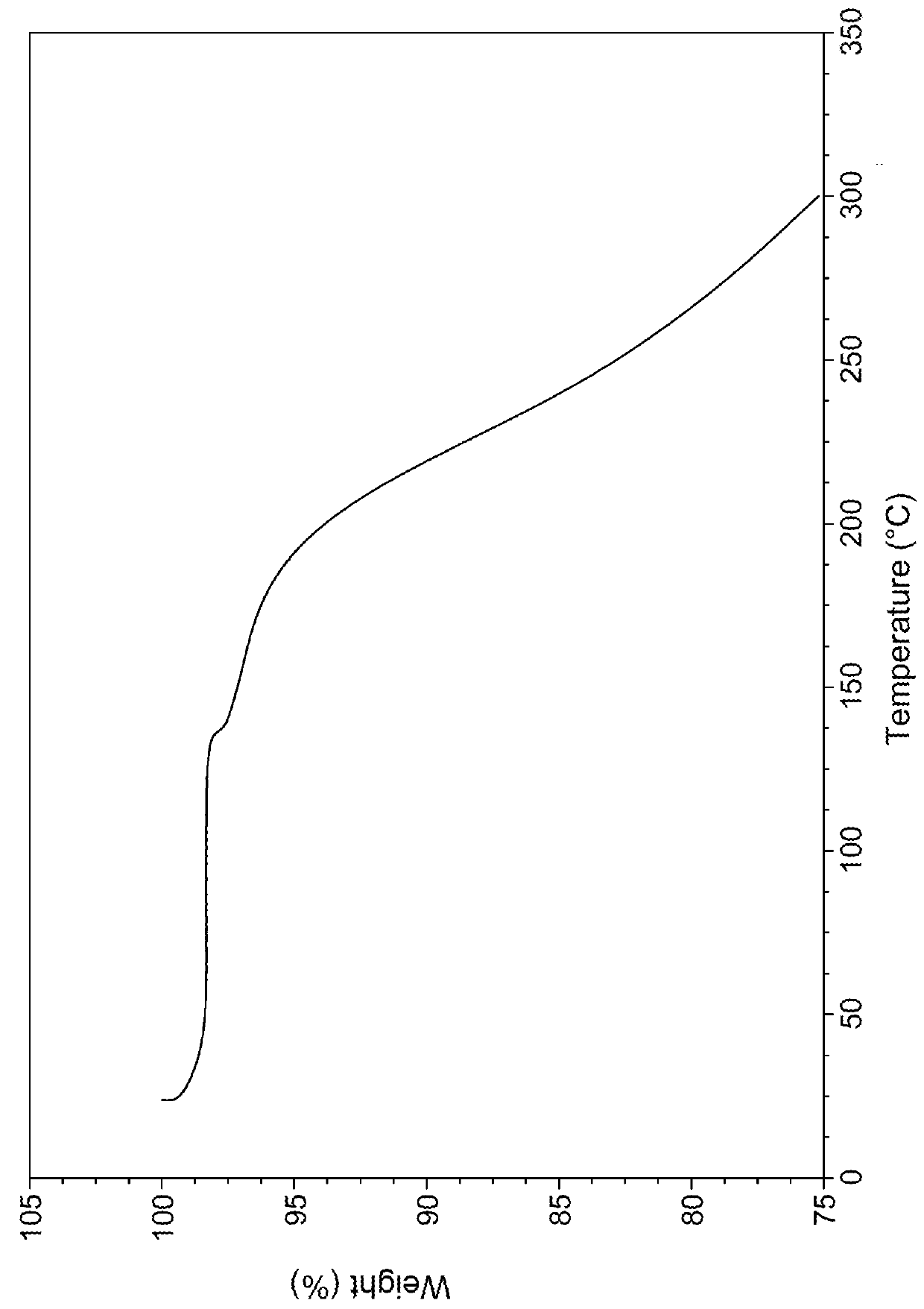

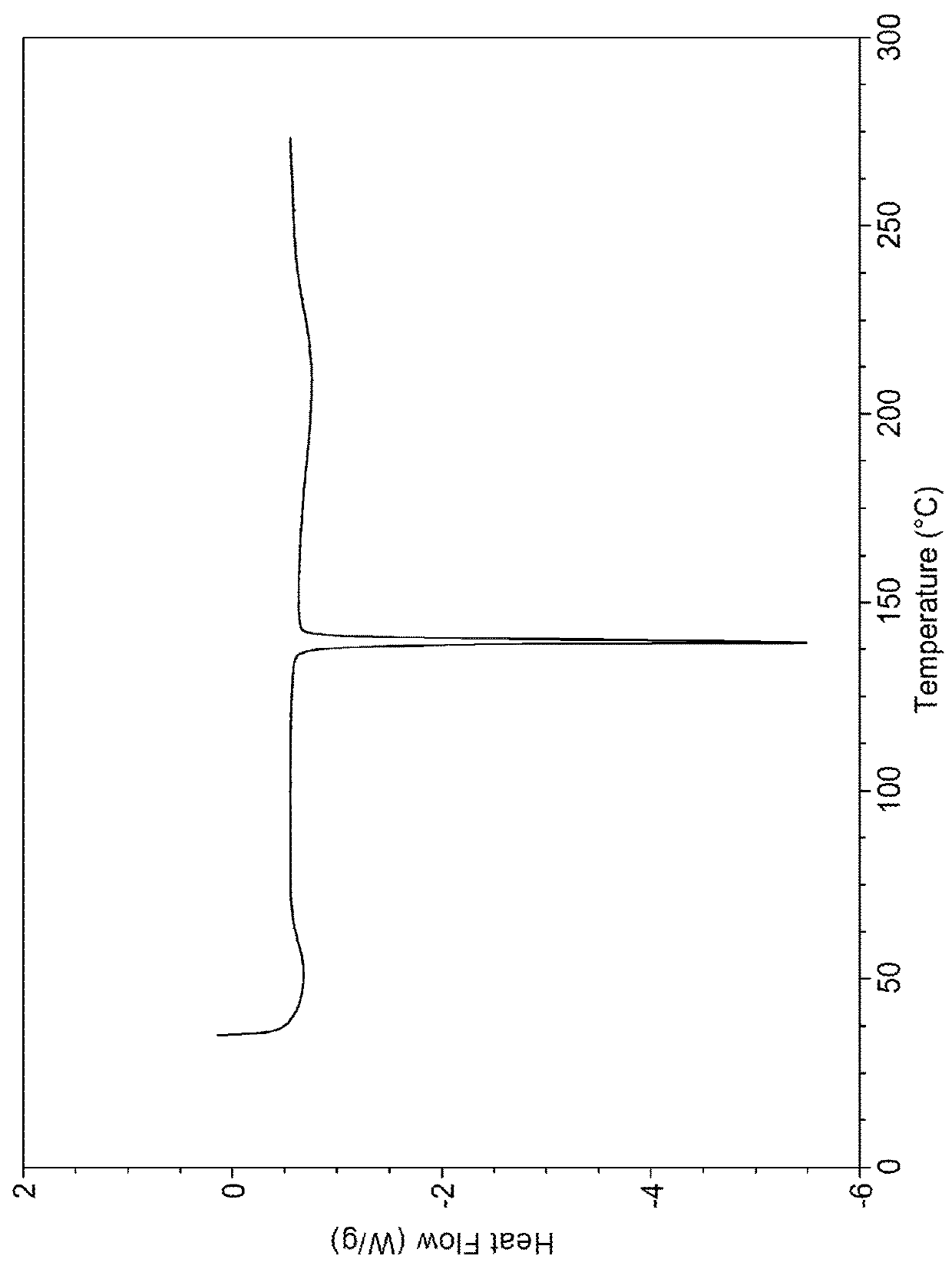

Vortioxetine Pyroglutamate

ActiveUS20190210987A1Organic active ingredientsNervous disorderCombinatorial chemistryPharmaceutical Substances

The present invention provides vortioxetine pyroglutamate salt and pharmaceutical compositions comprising said salt

Owner:H LUNDBECK AS

Antibodies to Pyroglutamate Amyloid-B and Uses Thereof

ActiveUS20200165328A1Nervous disorderMicrobiological testing/measurementDiseaseAntigen Binding Fragment

The invention provides an antibody or antigen binding fragments thereof that binds to 3pE Aβ and methods of making and using the antibody or antigen binding fragment thereof, including use for formulations, administration and kits. The antibody and antigen binding fragments thereof and methods disclosed are useful for diagnosis, prognosis and treatment of Alzheimer's disease or other β-amyloid-related diseases.

Owner:JANSSEN PHARMA NV

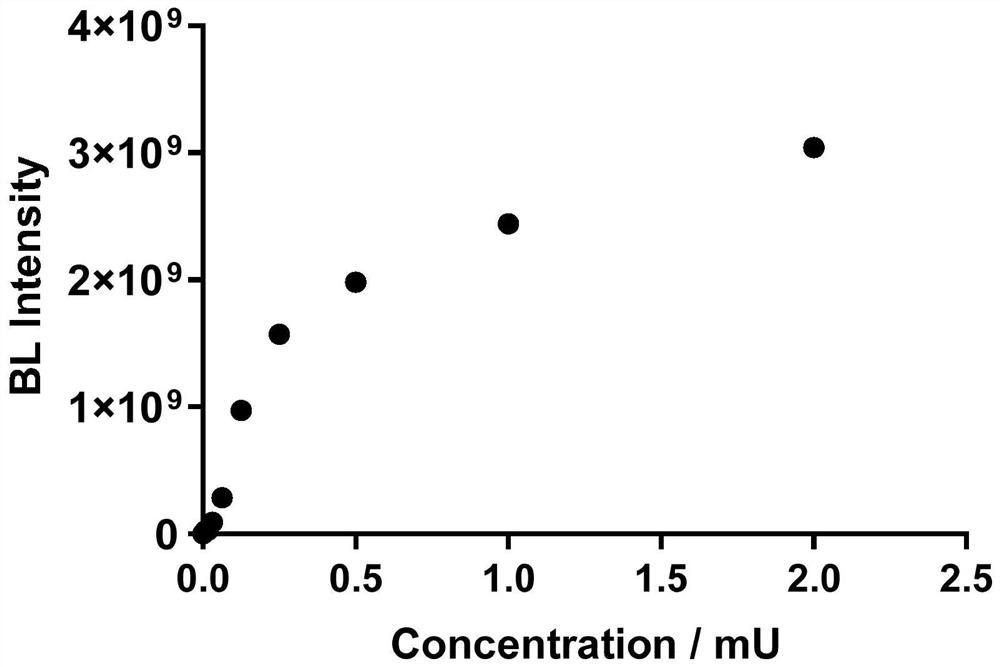

A preparation method and application of a bioluminescent probe for detecting pyroglutamate aminopeptidase

ActiveCN110563718BIncreased sensitivityGood choiceOrganic chemistryChemiluminescene/bioluminescenceChemical compoundGlutamine

The invention discloses a compound represented by formula I. The invention also discloses the use of the compound represented by formula I in preparing bioluminescent probes, especially bioluminescent probes for detecting pyroglutamate aminopeptidase. The probe provided by the invention shows good sensitivity, selectivity and biocompatibility to the target product. The probe provided by the invention can not only detect pyroglutamate aminopeptidase with good linearity and semi-quantitatively in an in vitro environment, but also has the ability to visually detect endogenous pyroglutamate aminopeptidase at the living level. The preparation method of the probe of the present invention is simple, high in yield, low in cost, high in efficiency, strong in specificity, fast and sensitive in substrate detection, and can realize qualitative and semi-quantitative detection and analysis of pyroglutamate aminopeptide at the same time Enzymes are easy to popularize and apply.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

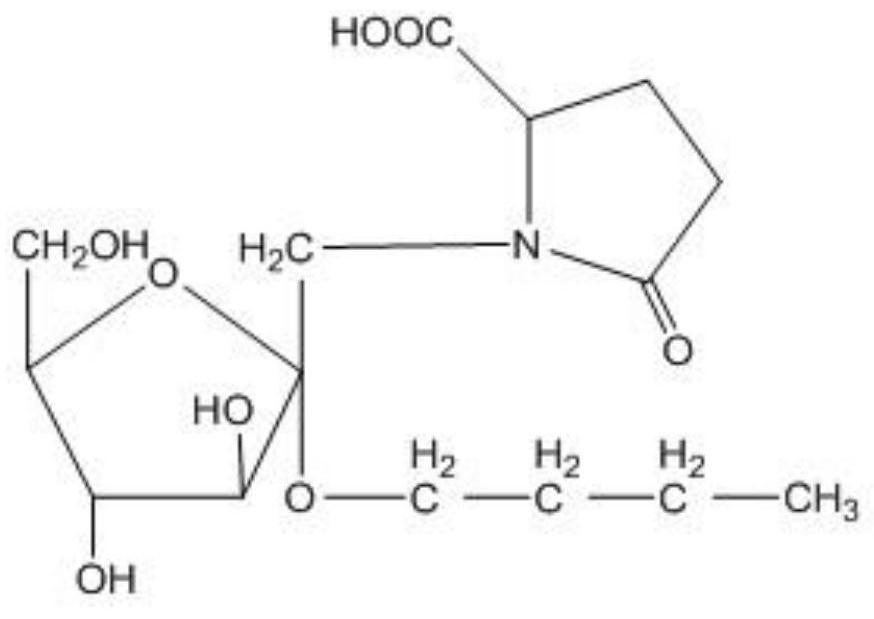

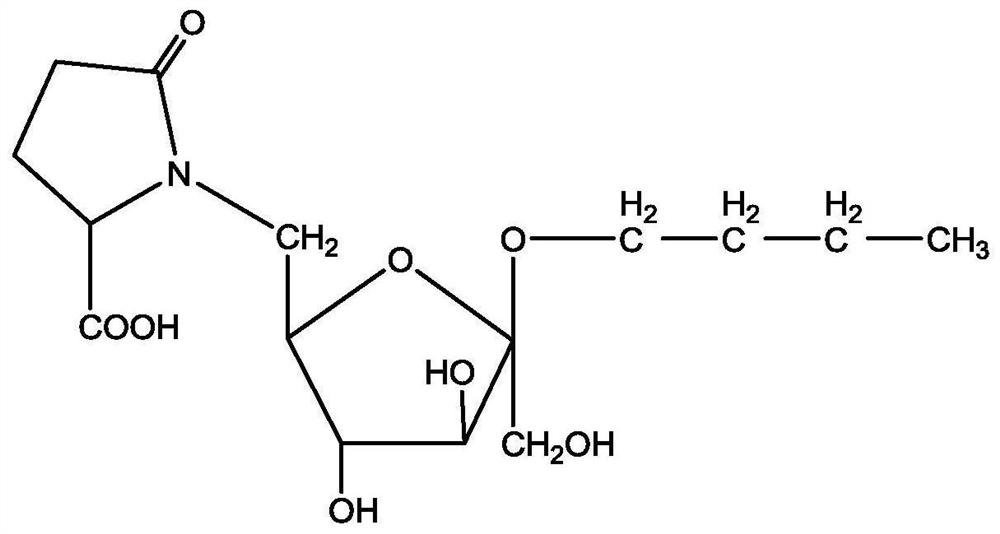

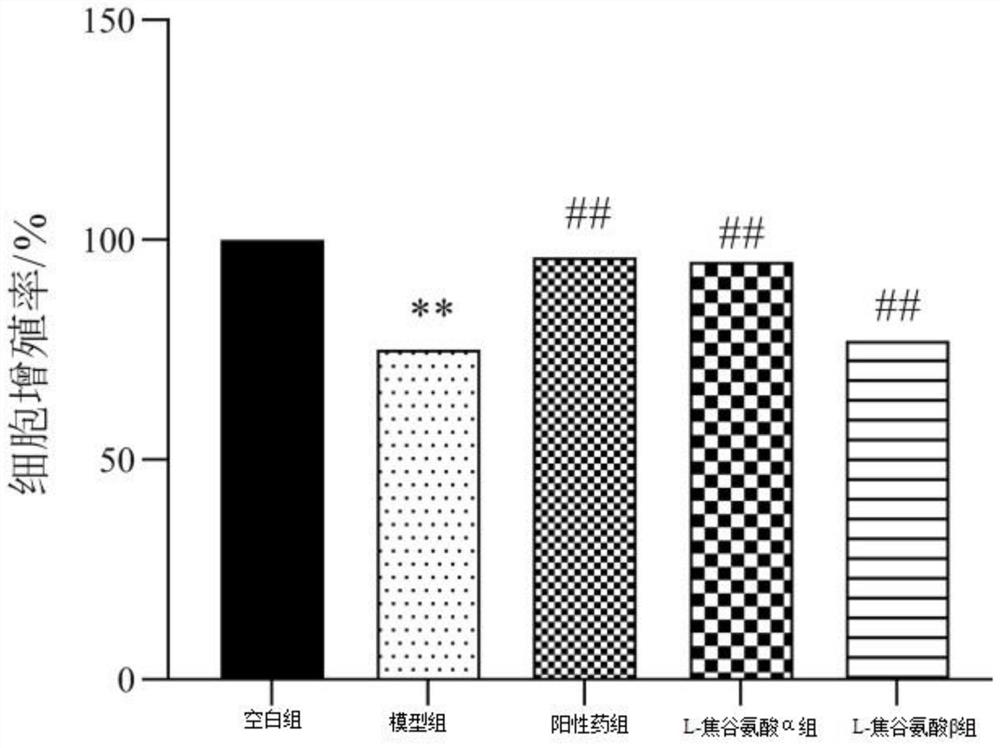

Novel application of n-butanol-2-O-(L-pyroglutamate-N-6-)-alpha-D-fructofuranoside

ActiveCN111686122AExcellent anti-AD effectProduce protective effectOrganic active ingredientsNervous disorderDiseasePerceived cognitive abilities

The present invention discloses novel application of n-butanol-2-O-(L-pyroglutamate-N-6-)-alpha-D-fructofuranoside, including application in Alzheimer's disease (AD), application in neuronal cell proliferation, application in improvement of learning and memory and cognitive ability and application in inhibiting the activity of AchE, increasing the content of ChAT and Ach. L-pyroglutamate alpha inthe present invention can bind to a muscarinic receptor M3 due to the spatial configuration of the L-pyroglutamate alpha, after the L-pyroglutamate alpha binds to the muscarinic receptor M3, the Ach in the brain of an AD patient is retained, so that the content of Ach is increased, while L-pyroglutamate beta cannot bind to the muscarinic receptor M3, which also shows that L-pyroglutamate alpha hasexcellent AD resisting function. The present invention provides an effective basis for L-pyroglutamate alpha in resisting AD through molecular biology, thereby providing new ideas for the developmentof anti-AD drugs.

Owner:HEILONGJIANG UNIV OF CHINESE MEDICINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for synthesizing tert-butyl N-[(3R, 6R)-6-methylpiperidine-3-yl] carbamate by chemical enzyme method Method for synthesizing tert-butyl N-[(3R, 6R)-6-methylpiperidine-3-yl] carbamate by chemical enzyme method](https://images-eureka.patsnap.com/patent_img/4cb0bc21-c9c5-4f8a-b45b-db2c75864f44/HDA0002903853230000011.png)

![Method for synthesizing tert-butyl N-[(3R, 6R)-6-methylpiperidine-3-yl] carbamate by chemical enzyme method Method for synthesizing tert-butyl N-[(3R, 6R)-6-methylpiperidine-3-yl] carbamate by chemical enzyme method](https://images-eureka.patsnap.com/patent_img/4cb0bc21-c9c5-4f8a-b45b-db2c75864f44/HDA0002903853230000012.png)

![Method for synthesizing tert-butyl N-[(3R, 6R)-6-methylpiperidine-3-yl] carbamate by chemical enzyme method Method for synthesizing tert-butyl N-[(3R, 6R)-6-methylpiperidine-3-yl] carbamate by chemical enzyme method](https://images-eureka.patsnap.com/patent_img/4cb0bc21-c9c5-4f8a-b45b-db2c75864f44/BDA0002903853220000011.png)