Honeycomb manganese denitration catalyst and preparation method thereof

A denitrification catalyst and honeycomb technology, which is applied in the field of honeycomb manganese-based denitration catalyst and its preparation, can solve problems such as cracking and large temperature difference between inner and outer surfaces, and achieve high denitrification activity, increased loading area, and excellent pore structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

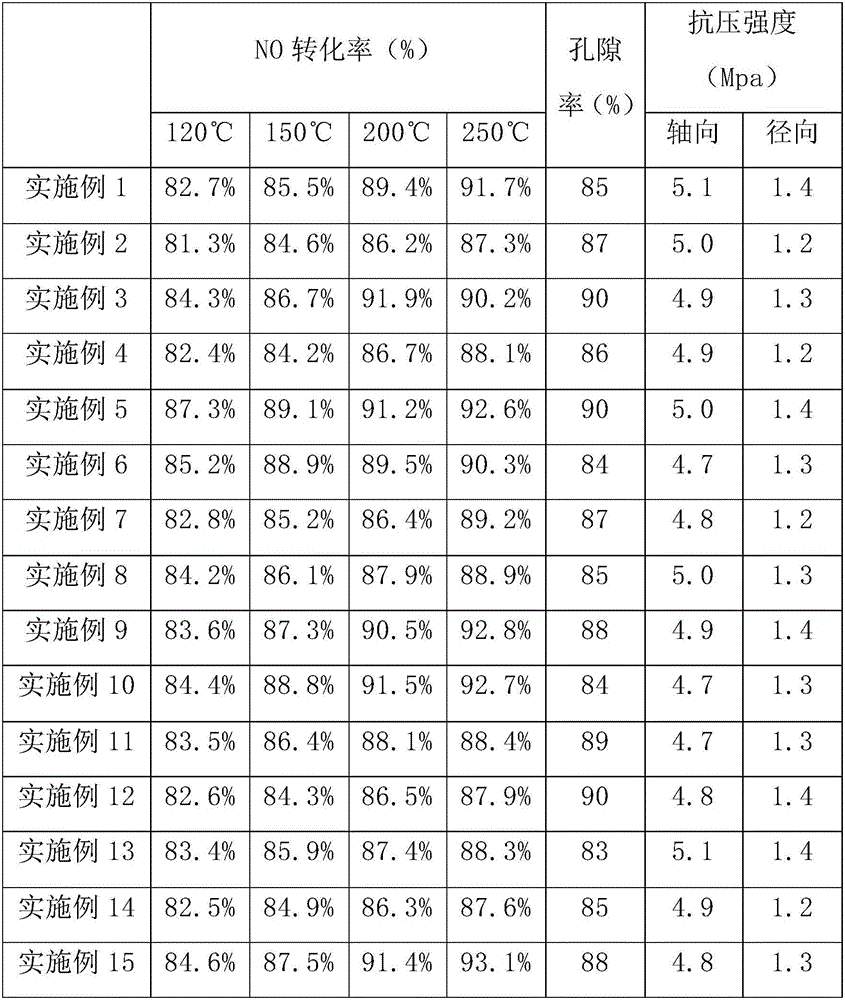

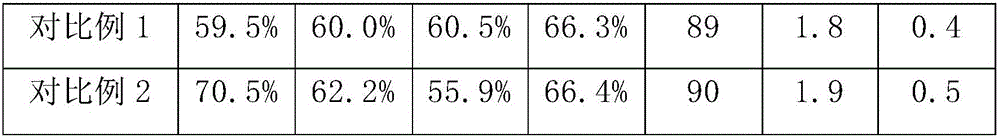

Examples

preparation example Construction

[0025] A kind of preparation method of honeycomb manganese series denitration catalyst that one embodiment of the present invention proposes, it comprises the following steps:

[0026] 1) dissolving manganese salt and complexing agent in water, adding titanium dioxide, stirring, ultrasonic impregnation, drying, and grinding to obtain Mn-Ti oxide solid particles; wherein, the concentration of the complexing agent is 3-5mol / L, the molar ratio of manganese salt to complexing agent is 65-187:1; wherein, the frequency of ultrasound is 10-30KHz, and the time of ultrasonic impregnation is 1-2 hours, and the manganese salt and titanium dioxide can be fully contacted by ultrasonic impregnation ;The drying temperature is 105-250°C, and the drying time is 20-30h. By drying, the manganese salt is decomposed in advance to form manganese oxides and release gas, which can reduce the heat loss of the honeycomb body during the drying and calcination process. The amount of volatile matter is n...

Embodiment 1

[0040] Dissolve 9.76kg of 50wt% manganese nitrate and 100ml of oxalic acid solution with a concentration of 3mol / L in 5000mL of deionized water, add 10kg of titanium dioxide powder, stir for 0.5h, ultrasonically impregnate at 25KHz for 2h, and dry in an oven at 205°C for 24h , grinding to obtain a particle size of 300-400 purpose Mn-Ti oxide solid particles; 988gCo(NO 3 ) 3 ·6H 2 O and 930gCe(NO 3 ) 3 ·6H 2 O was dissolved in 3000ml of water to obtain a mixed metal solution; 10kg of Mn-Ti oxide solid particles were added to the mixed metal solution and stirred, and then 500g of activated carbon, 100g of carboxymethyl cellulose and 100g of polyethylene oxide, 300g of glycerin, and 500g were added Glass fiber to obtain a mixed mud mass; place the mixed mud mass in a mud mill for vacuum mixing 3 times, seal and stale the mixed mud for 2 days, send it into an extruder, and extrude it into a honeycomb body blank; The honeycomb body blank was dried in an oven at 60°C for 6 hour...

Embodiment 2

[0042] Dissolve 13.02kg of 50wt% manganese nitrate and 100ml of 4mol / L oxalic acid solution in 3500mL of deionized water, add 10kg of titanium dioxide powder, stir for 0.5h, ultrasonically impregnate at 20KHz for 1h, and dry in an oven at 185°C for 20h , grinding to obtain a particle size of 300-400 mesh Mn-Ti oxide solid particles; 993gFeSO 4 ·7H 2 O and 680gCe(C 2 h 3 o 2 ) 3 Dissolve in 3000ml of water to obtain a mixed metal solution; add 10kg of Mn-Ti oxide solid particles into the mixed metal solution and stir, then add 400g of starch, 100g of carboxymethyl cellulose and 100g of polyethylene oxide, 200g of soybean oil, and 400g of glass fibers to obtain a mixed mud mass; place the mixed mud mass in a mud mill for vacuum mixing 2 times, seal and stale the mixed mud material for 3 days, send it into an extruder, and extrude it into a honeycomb body blank; The honeycomb body blank was dried in an oven at 50°C for 7 hours, then the temperature was raised to 100°C for 13...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Axial compressive strength | aaaaa | aaaaa |

| Radial compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com