Strontium titanate-titanium dioxide composite nanotube array film and preparation method and application thereof

A nanotube array and titanium dioxide technology, which is applied in the field of semiconductor nanocomposite material preparation, can solve the problems of easy recombination of excited charges and large band gap, and achieve simple adjustment of reaction temperature and time, high selectivity, and mild synthesis process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

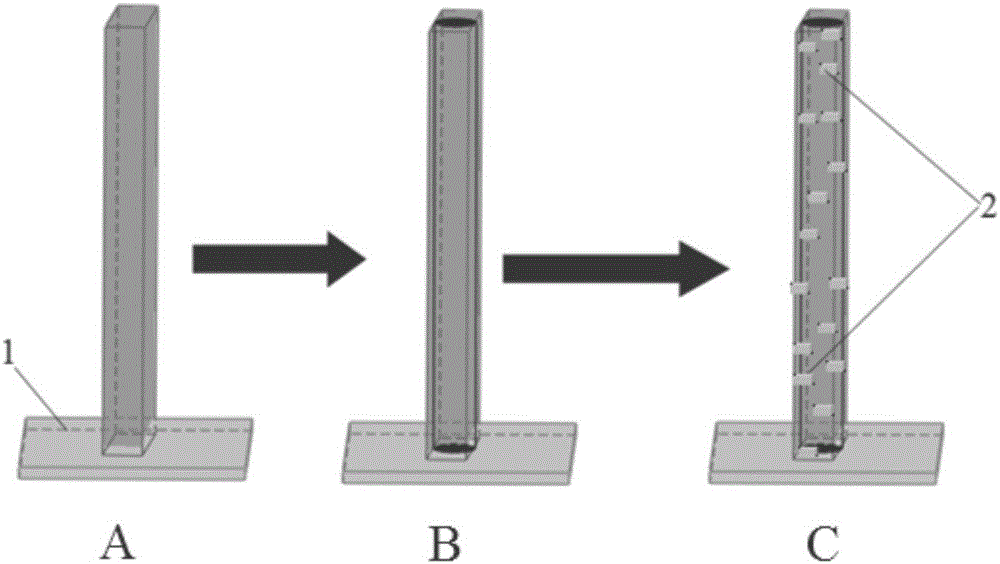

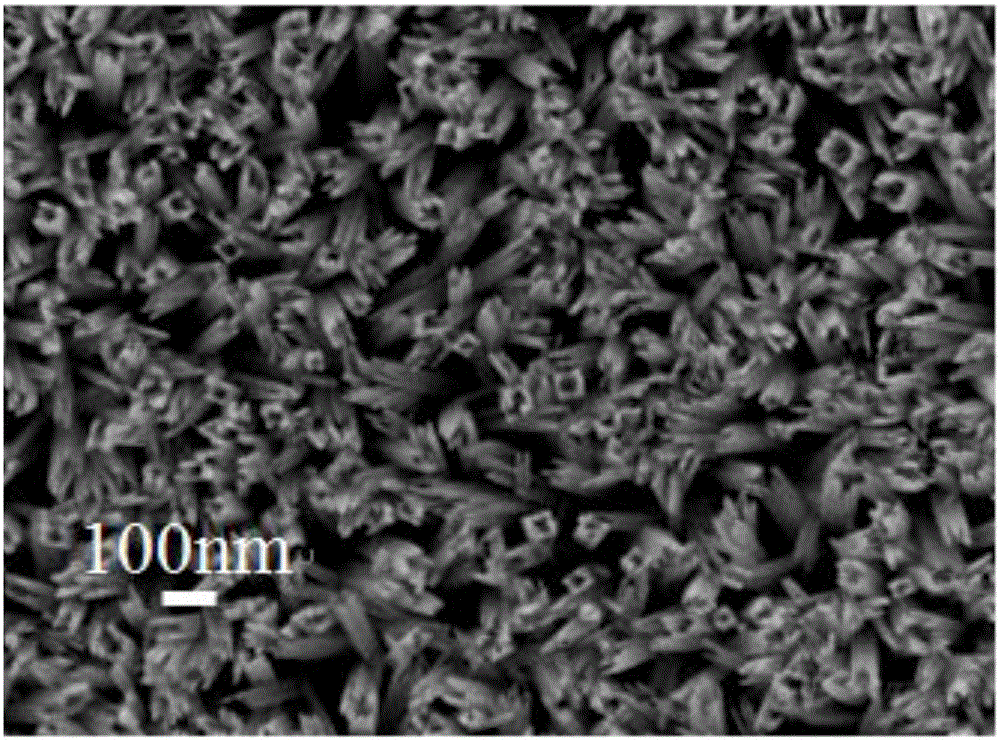

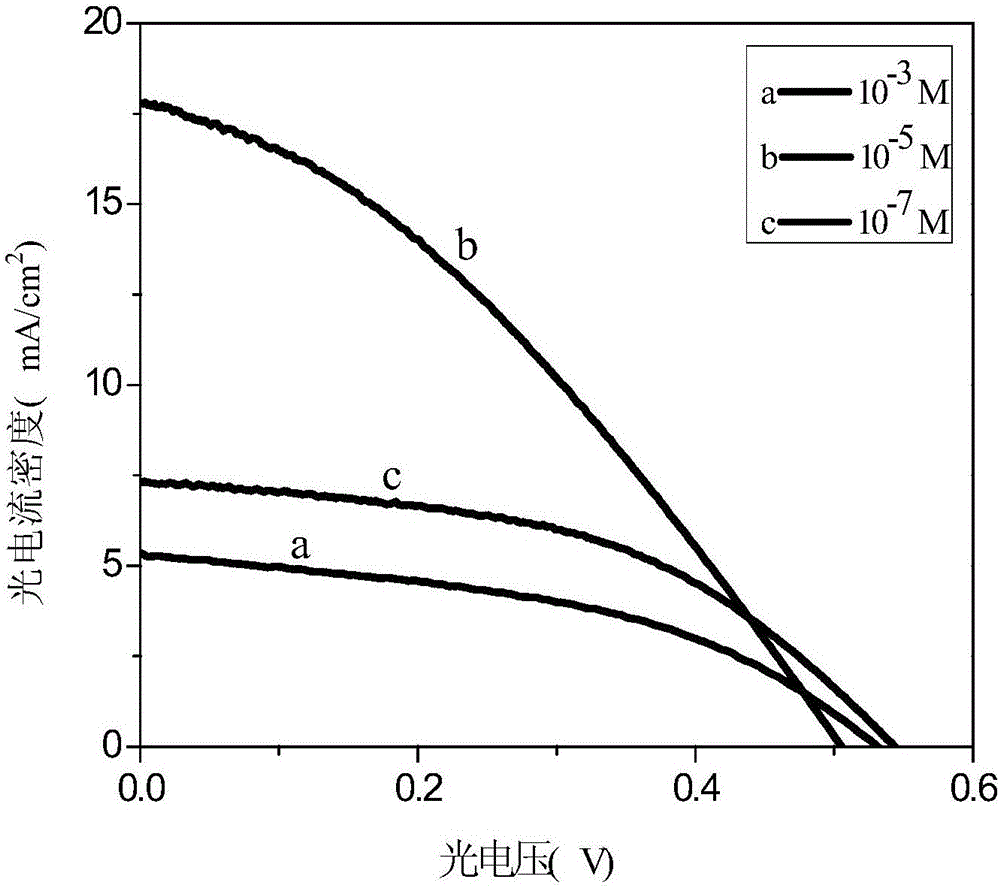

[0025] Using n-butyl titanate as the titanium source precursor, concentrated hydrochloric acid as the etchant, and strontium hydroxide solution as the strontium source, the strontium titanate-titanium dioxide composite nanotube array film was prepared by hydrothermal method. The operation steps are as follows:

[0026] (1), prepare hydrochloric acid with a concentration of 36.5% and deionized water according to the volume ratio of 1:6, 1:4, 1:2, 1:1, 2:1, 4:1, 6:1 respectively 30mL of the mixed solution was stirred with a magnetic stirrer for 5min, and then 0.6mL of n-butyl titanate was added thereto, and after stirring for 15min, a transparent and clear solution was obtained, which was used as a reaction solution for use;

[0027] (2) Take a piece of FTO (fluorine-doped tin oxide) conductive glass, tilt it into the autoclave with the conductive side facing down, pour the reaction solution into the autoclave, put it in an oven for 4 hours at 150°C for hydrothermal reaction, and...

Embodiment 2

[0037](1), after stirring 15mL 36.5% concentrated hydrochloric acid and 15mL deionized water with a magnetic stirrer for 5min, add 0.1mL, 0.2mL, 0.4mL, 0.6mL, 0.8mL, 1.0mL of n-butyl titanate respectively, After stirring for 15 minutes, a transparent and clear solution was obtained, which was used as a reaction solution;

[0038] Steps (2)~(6) are the same as in Example 1;

[0039] (7) After the reaction, cool down to room temperature with the furnace, take out the porcelain boat, and obtain strontium titanate-titanium dioxide composite nanotube array films prepared with different amounts of n-butyl titanate in the reaction substrate during the first hydrothermal reaction , and keep away from light.

Embodiment 3

[0041] (1) After stirring 15mL of 36.5% concentrated hydrochloric acid and 15mL of deionized water with a magnetic stirrer for 5 minutes, add 0.6mL of n-butyl titanate to it, and after stirring for 15 minutes, a transparent and clear solution was obtained, which was used as a reaction solution for use;

[0042] (2) Take a piece of FTO conductive glass, put it into the autoclave obliquely, with the conductive side down, transfer all the reaction solution into the autoclave, put it into the oven at 80°C, 120°C, 150°C, 180°C , hydrothermal reaction at 210°C and 240°C for 4 hours. After the reaction is completed, take out the autoclave, cool it down to room temperature naturally, take out the FTO conductive glass, rinse it with deionized water, and dry it for use;

[0043] Steps (3)~(6) are the same as in Example 1;

[0044] (7) After the reaction, cool down to room temperature with the furnace, take out the porcelain boat, and obtain strontium titanate-titanium dioxide composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com