Extraction method of phycobiliprotein of nostoc sphaeroides kutzing

A technology of phycobiliprotein and extraction method of Gexianmi, which is applied in the direction of chemical instruments and methods, decapeptides, peptides, etc., can solve the problem of not considering the edible value of phycobiliprotein, manpower, material resources and energy consumption, and can not guarantee the final To improve the safety of finished products and achieve the effects of increasing phycobiliprotein content, easy storage and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 adopts the method of the present invention to carry out laboratory small test crudely extract phycobiliprotein

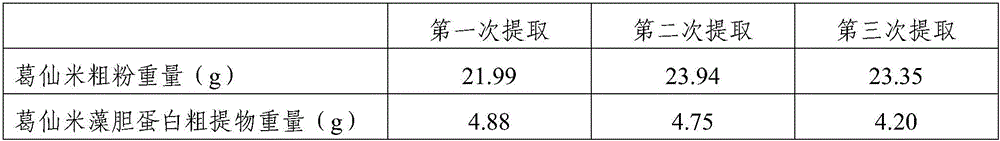

[0026] Grind the dry matter (moisture content 11%) through the sun or dry water to 60 mesh with a universal pulverizer, and take 21.99g, 23.94g, and 23.35g of the pueraria coarse powder and place them in a beaker Add 1100 g of purified water, let it stand at room temperature for 6 hours, centrifuge at 8000 r / min for 15 min, filter to obtain a crude extract, and freeze-dry the crude extract to obtain a crude extract of phycobiliproteins from Pueraria japonica. The results are shown in Table 1 below:

[0027] Table 1

[0028]

[0029]

[0030] It can be seen from the above table 1 that the yield of the crude extract obtained from the three extractions is relatively high, all of which are more than 20%, and the average value is 22.5%. It is verified that the method of the present invention has good reproducibility through three repeated expe...

Embodiment 2

[0031] Embodiment 2 adopts the method of the present invention to carry out laboratory small test crude extraction phycobiliprotein

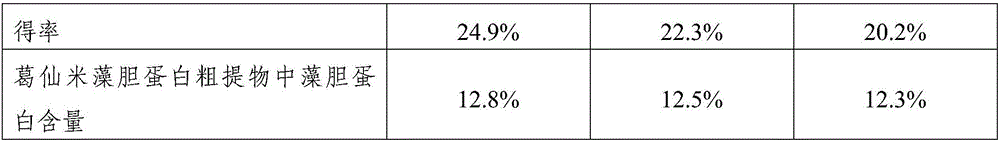

[0032] Grind the dry matter (moisture content 11%) through the sun or dry water to 80 mesh with a universal pulverizer, and take 25.12g, 25.30g, and 25.60g of the pueraria coarse powder and place them in a beaker Add 1260g of purified water, let it stand at room temperature for 6 hours, centrifuge at 8000r / min for 15min, filter to obtain a crude extract, freeze-dry the crude extract to obtain a crude extract of phycobiliprotein from Pueraria japonica. The results are shown in Table 2 below:

[0033] Table 2

[0034]

[0035] It can be seen from the above table 2 that the yield of the crude extract obtained from the three extractions is relatively high, all of which are more than 10%, and the average value is 11.1%. It is verified that the method of the present invention has good reproducibility through three repeated experiments.

Embodiment 3

[0036] Embodiment 3 adopts the method of the present invention to carry out the crude extraction phycobiliprotein of laboratory small test

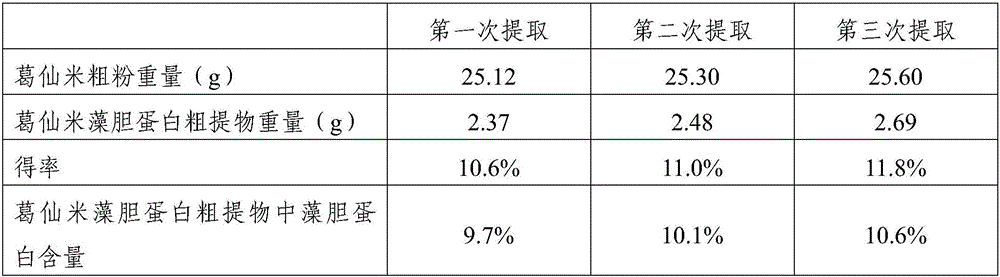

[0037] Grind the dry matter (moisture content 11%) through the sun or dry water to 20 mesh with a universal pulverizer, and take 24.87g, 25.45g, and 25.00g of the pueraria coarse powder and place them in a beaker Add 1260g of purified water, let it stand at room temperature for 6 hours, centrifuge at 8000r / min for 15min, filter to obtain a crude extract, freeze-dry the crude extract to obtain a crude extract of phycobiliprotein from Pueraria japonica. The results are shown in Table 3 below:

[0038] table 3

[0039]

[0040]

[0041] It can be seen from the above table 3 that the yield of the crude extract obtained by three extractions is relatively high, all of which are more than 10%, and the average value is 13.2%. It is verified that the method of the present invention has good reproducibility through three repeated experiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com