Lithium ferric manganese phosphate-tungsten disulfide nanometer lithium cell positive material and preparation method thereof

A technology of lithium iron manganese phosphate and tungsten disulfide, which is applied in battery electrodes, batteries, nanotechnology and other directions, can solve the problems of poor cycle stability, low temperature stability, and high temperature stability of layered manganese oxide lithium structure, and achieves charging and discharging. Stable circulation structure, excellent high and low temperature resistance, buffer volume expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

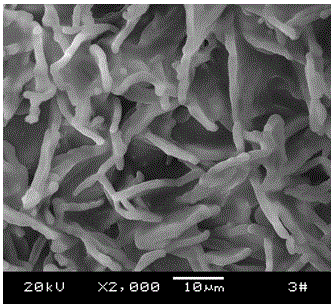

Image

Examples

Embodiment 1

[0034] (1) The molar ratio of lithium hydroxide, ferric chloride and phosphoric acid Li:Fe:P= 1:0.99:1.08 is mixed and dissolved in water, and the molar ratio of the amount of water to the lithium atom in the lithium compound used is 30:1, Stir and disperse at a high speed of 1400rpm in a high-speed mixer for 5min to form a lithium iron phosphate precursor;

[0035] (2) Mix manganese dioxide, manganese tetroxide and lithium carbonate in a molar ratio of manganese dioxide: manganese tetroxide: lithium carbonate = 1:0.4:0.92, and stir at a high speed of 1400rpm in a high-speed mixer Disperse for 3min to obtain manganese oxide lithium precursor;

[0036] (3) At room temperature, first mix sodium tungstate, hydroxylamine hydrochloride and thiourea in a molar ratio of sodium tungstate:hydroxylamine hydrochloride:thiourea=1:1.5:3, add a certain amount of surfactant trimethyl ten Hexaalkylammonium bromide, reacted at a constant temperature of 100 °C for 10 hours, and slowly grown to o...

Embodiment 2

[0042] (1) Mix and dissolve lithium acetate, ferric chloride and ammonium phosphate in a molar ratio Li:Fe:P= 1:1:1 in water, and the molar ratio of the amount of water to the lithium atom in the lithium compound used is 100:1 , in a high-speed mixer at a speed of 2000rpm for high-speed stirring and dispersing for 5min to form a lithium iron phosphate precursor;

[0043] (2) Mix manganese dioxide, manganese tetroxide and lithium carbonate in a molar ratio of manganese dioxide: manganese tetroxide: lithium carbonate = 1:0.5:1, and stir at a high speed of 5000rpm in a high-speed mixer Disperse for 5min to obtain manganese oxide lithium precursor;

[0044] (3) At room temperature, first mix sodium tungstate, hydroxylamine hydrochloride and thiourea in a molar ratio of sodium tungstate: hydroxylamine hydrochloride: thiourea = 1:2:3, add a certain amount of surfactant dodecyl Sodium sulfonate, react at 150 ℃ constant temperature for 8 hours to obtain tungsten disulfide nanosheets;...

Embodiment 3

[0050] (1) Mix and dissolve lithium nitrate, ferric sulfate, and ammonium dihydrogen phosphate in a molar ratio Li:Fe:P= 1:1.03:1.08 in water, and the molar ratio of the amount of water to the lithium atom in the lithium compound used is 300: 1. Stir and disperse at a high speed of 1400rpm in a high-speed mixer for 3min to form a lithium iron phosphate precursor;

[0051] (2) Mix manganese dioxide, manganese tetroxide, and lithium carbonate in a molar ratio of manganese dioxide: manganese tetroxide: lithium carbonate = 1:0.8:0.92, and stir at a high speed of 5000rpm in a high-speed mixer Disperse for 4min to obtain manganese oxide lithium precursor;

[0052] (3) At room temperature, firstly mix sodium tungstate, hydroxylamine hydrochloride and thiourea in a molar ratio of sodium tungstate: hydroxylamine hydrochloride: thiourea = 1: 1.5: 3.5), and add a certain amount of surfactant polyethylene glycol Alcohol 400, reacted at a constant temperature of 200 °C for 8 hours to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com