Bonding-assisting biological mineralization material and applications thereof in biomimetic mineralization

A biomineralization and bonding technology, applied in the field of biomimetic biomaterial engineering, can solve the problems of short action time and poor mineralization effect, and achieve the effects of convenient storage, good bonding strength, and simple and effective application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1.1 Synthesis of nACP particles (PAA-ACP) stabilized with non-collagen analog polyacrylic acid (PAA)

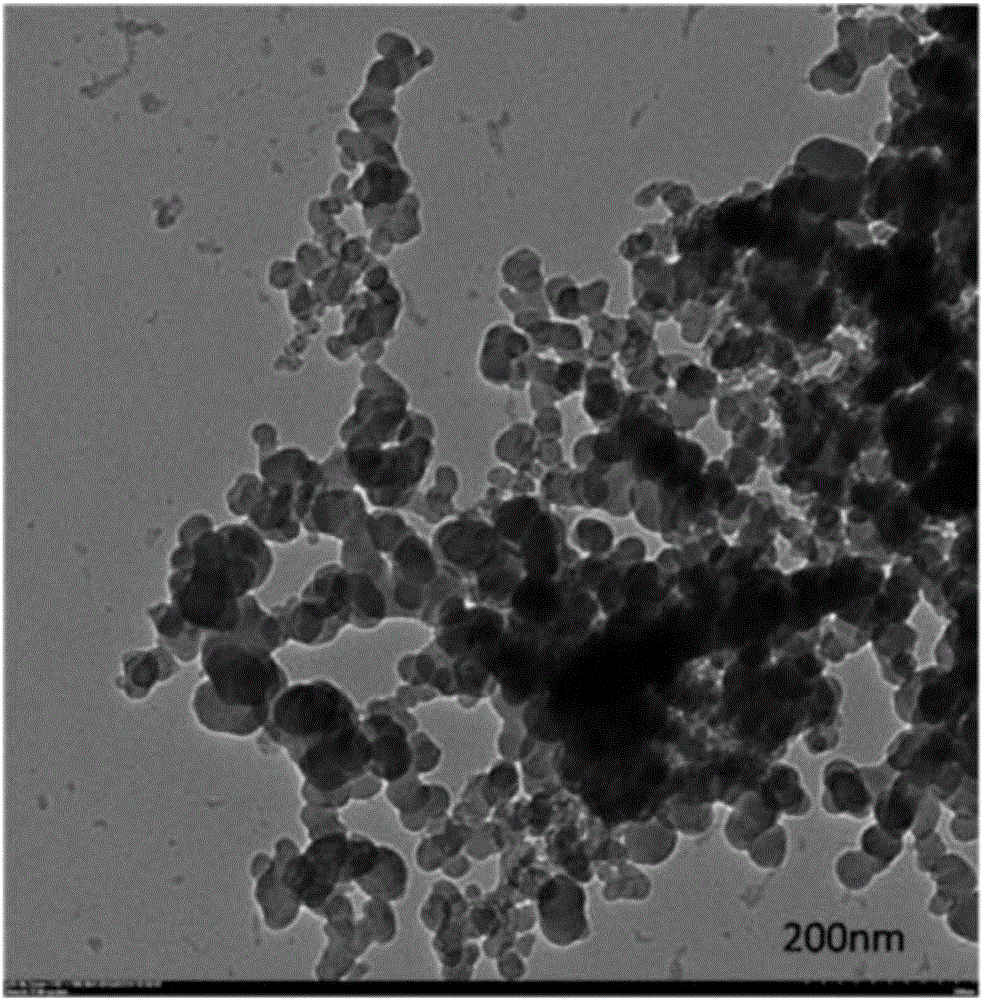

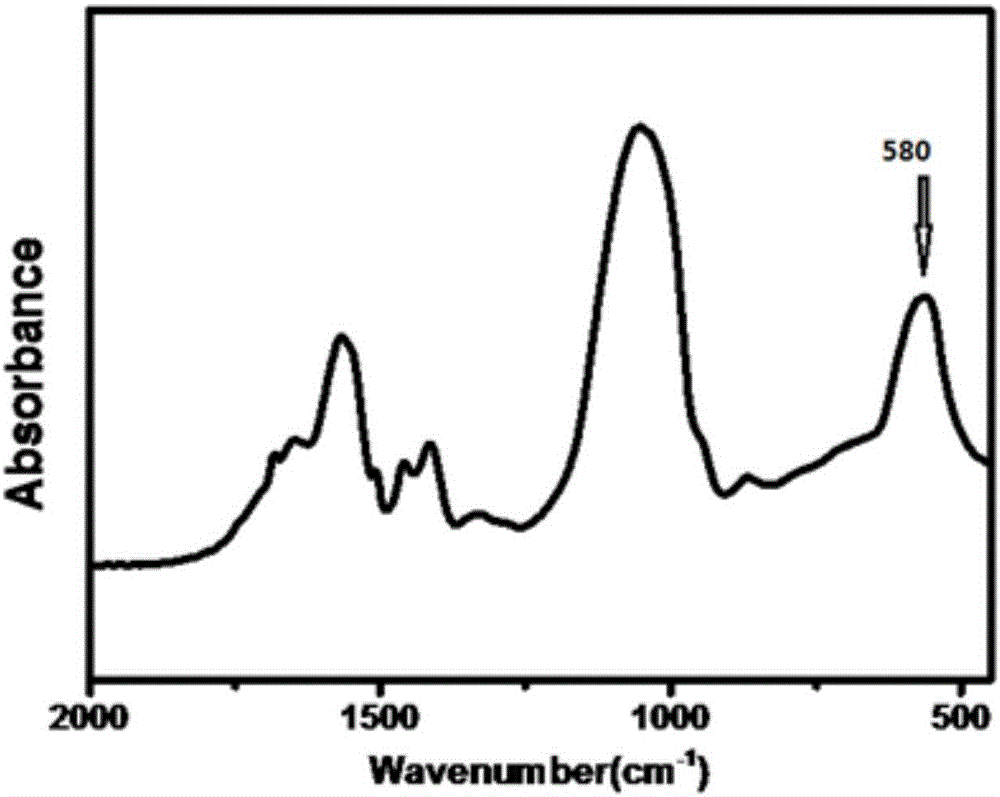

[0034] Using the solution precipitation method, drop an equal volume of calcium chloride solution into the mixed solution of sodium dihydrogen phosphate and PAA. During the titration process, the pH value of the solution is controlled at 9.5±0.5, and the titration time is controlled at 0.5-1h. The final molar concentration ratio of calcium and phosphorus is 10:6, and the final concentration of PAA is 500ug / ml. Centrifuge and place in a vacuum oven overnight. The next day, the synthesized nACP particles were stored in polyethylene plastic bottles sealed at room temperature. Transmission electron microscope (TEM) observation observes the regularity of ACP particle morphology that PAA is stable, and size is about 20-100nm (attachment figure 1 ). The ACP synthesized by Fourier transform infrared analysis (FTIR) is at 580cm -1 There is a peak at the place, no cleavage o...

Embodiment 2

[0040] 2.1 Synthesis of nACP particles (PAsp-ACP) stabilized with non-collagen analog polyaspartic acid (PAsp)

[0041] Using the solution precipitation method, mix the mixture of sodium dihydrogen phosphate and PAsp with an equal volume of calcium chloride solution for 10-30 minutes, the final concentration ratio of calcium and phosphorus is 10:6, and the final concentration of Pasp is 240ug / ml. Centrifuge and place in a vacuum oven overnight. The next day, the synthesized solid nACP particles were stored in polyethylene plastic bottles sealed at room temperature. Observation and observation of ACP morphological rules with a transmission electron microscope (TEM), the size is about 20-80nm (attached Figure 6 ). The synthesized ACP detected by XRD is an amorphous phase (attached Figure 7 ).

[0042] 2.2 Preparation of recombinant type I collagen model, simulating dentin type I collagen: same as in Example 1

[0043] 2.3 Mineralization of monolayer recombinant type I col...

Embodiment 3

[0046] 3.1 Synthesis of nACP particles (PAA-ACP) stabilized with non-collagen analog polyacrylic acid (PAA) was the same as in Example 1, and the final concentration of PAA was 300ug / ml.

[0047] 3.2 Preparation of recombinant type I collagen model to simulate dentin type I collagen

[0048] Same as Example 1

[0049] 3.3 Mineralization of monolayer recombinant type I collagen

[0050] According to 5wt% of the dosage of the adhesive, the above-mentioned synthetic solid PAA-ACP particles are mixed with a commercial adhesive such as Clearfil S3 Bond adhesive, stirred evenly, and brushed on the TEM nickel mesh loaded with type I recombinant collagen , stand still for 30-60s, and light cure for 40s. Suspend the nickel mesh in the artificial saliva. After 21 days, TEM and SAED observed that the mineralization of the collagen appeared in the fiber, and the TEM picture was the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com