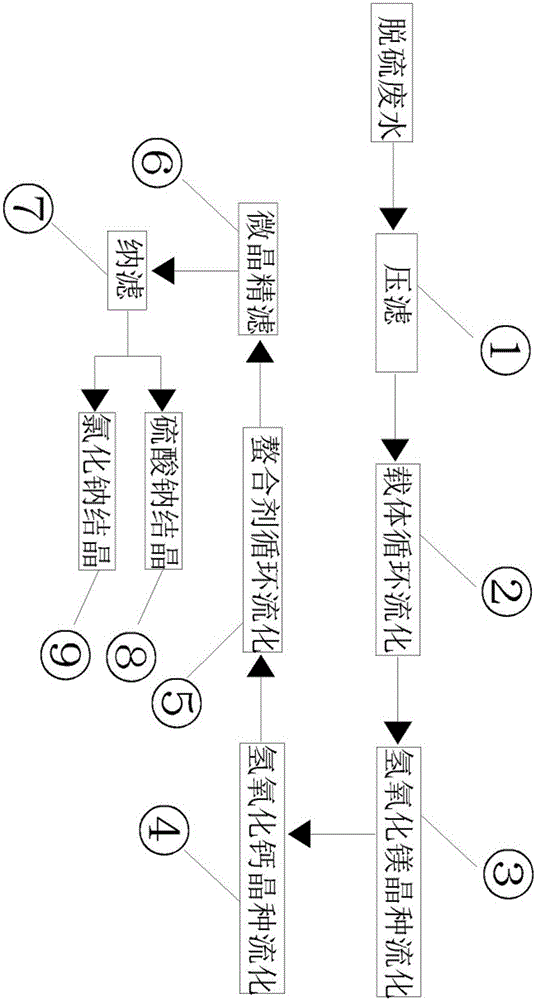

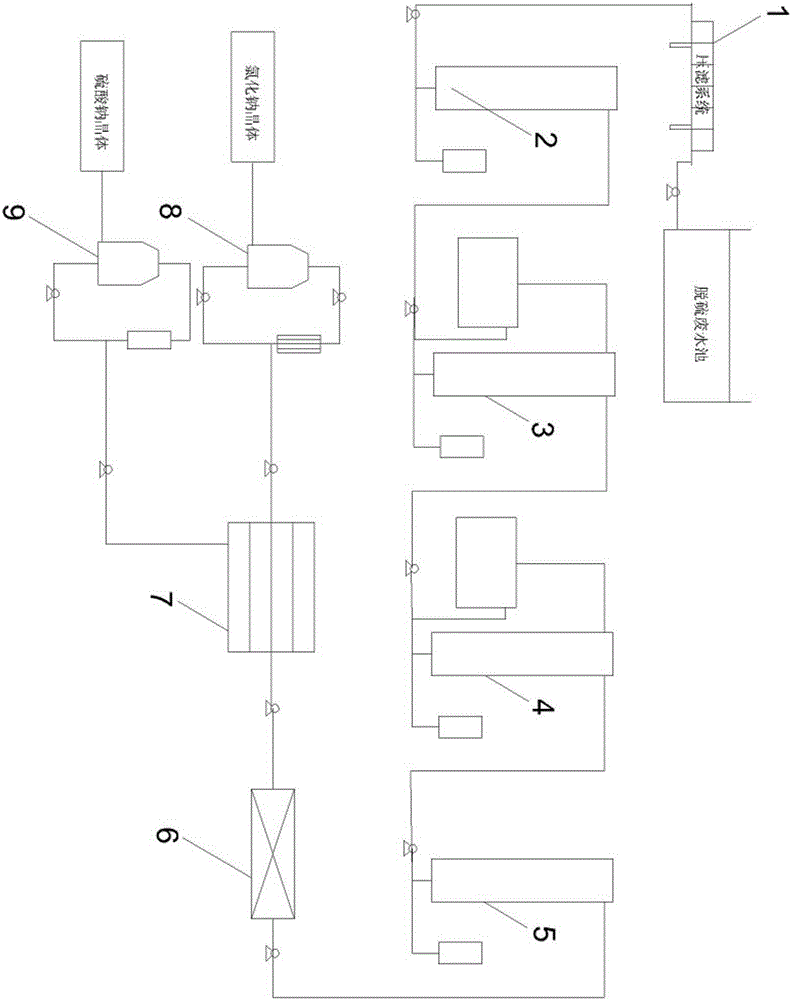

Multistage fluidized bed crystallization based desulfuration wastewater treatment method and system

A desulfurization wastewater and treatment system technology, applied in the direction of water/sewage multi-stage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of waste of resources, slow system feedback, difficult operability, etc., and achieve automatic control The effect of increasing the degree, improving the separation effect and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The desulfurization wastewater was carried out in several multi-stage fluidized bed operating conditions to obtain the following results:

[0057] 1. The pressure of the sludge pump in the filter press system 1 is 0.8MPa, the pressure of the squeeze pump is 1.0MPa, and the water content of the suspended matter sludge is reduced to below 30%; the filtrate passes through the carrier circulating fluidized bed, and passes through the heavy metal adsorbent and the porous channel The adsorption and collision of the carrier can reduce the desorption of heavy metals, and increase the effective contact time through circulating fluidization. The average removal rate of heavy metals in various desulfurization wastewater can reach more than 98%, and the minimum removal rate can reach 96%. Set the crystal seed The seed crystal dosing ratio of the fluidized bed is 1:5000, that is, 1 kg of seed crystals with a particle size of <2mm is added per ton of water to be treated, and the fluid...

Embodiment 2

[0062] The desulfurization wastewater was operated in several multi-stage fluidized bed setting conditions, and the following results were obtained:

[0063]1. The pressure of the sludge pump in the filter press system 1 is 0.4MPa, the pressure of the squeeze pump is 0.8MPa, and the water content of the suspended matter sludge is reduced to 45%; the filtrate passes through the carrier circulating fluidized bed, and passes through the heavy metal adsorbent and the porous carrier The adsorption and collision effects of heavy metals can reduce the desorption of heavy metals, and increase the effective contact time through circulating fluidization. The average removal rate of heavy metals in various desulfurization wastewater can reach more than 96%, and the minimum removal rate can reach 92%. Set the seed flow The seed crystal dosing ratio of the fluidized bed is 1:1000, that is, 3 kg of seed crystals with a particle size of <2mm are added per ton of water to be treated, and the f...

Embodiment 3

[0068] The desulfurization wastewater was operated in several multi-stage fluidized bed setting conditions, and the following results were obtained:

[0069] 1. The pressure of the sludge pump in the filter press system 1 is 0.7MPa, the pressure of the squeeze pump is 0.95MPa, and the water content of the suspended matter sludge is reduced to 35%; the filtrate passes through the carrier circulating fluidized bed, and passes through the heavy metal adsorbent and the porous carrier The adsorption and collision effects of heavy metals can reduce the desorption of heavy metals, and the effective contact time can be increased through circulating fluidization. The average removal rate of heavy metals in various desulfurization wastewater can reach more than 98%, and the minimum removal rate can reach 95%. Set the seed flow The seed crystal dosing ratio of the fluidized bed is 1:3000, that is, 3 kg of seed crystals with a particle size of <2 mm are added per ton of water to be treated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com