Chemical synthesis method of Pimobendan

A technology for chemical synthesis and pimobendan, applied in the direction of organic chemistry and the like, can solve the problems of unsuitable large-scale preparation of pimobendan, long reaction route, potential safety hazards, etc., and achieves low cost, short reaction period, corrosiveness and the like. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

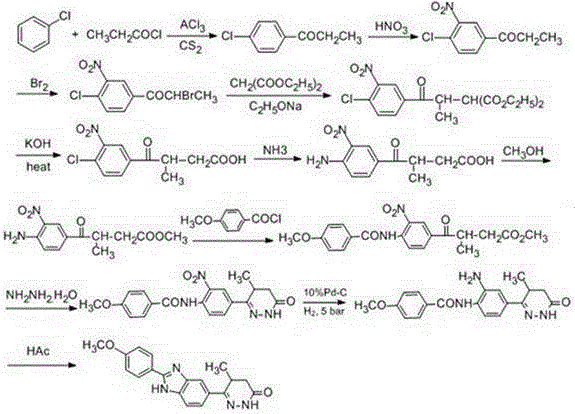

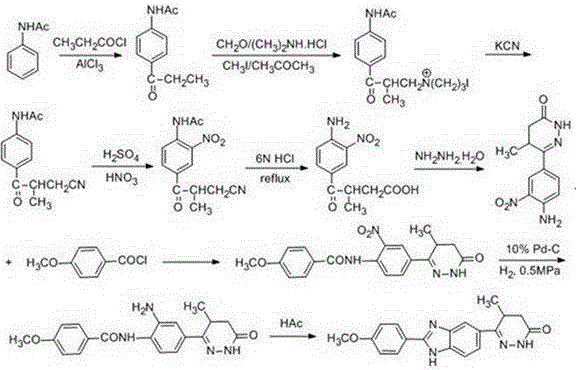

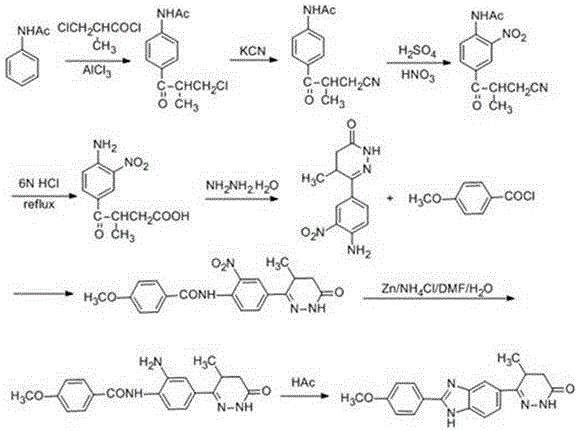

Method used

Image

Examples

Embodiment 1

[0035]

[0036]Step ①: Dissolve acetanilide (0.2 mol, 27g) in a mixed solvent of 45mL carbon disulfide and 45mL dichloromethane, stir at room temperature to obtain a colorless transparent solution, and add anhydrous aluminum trichloride (0.4 mol, 52.4g ) and potassium iodide (0.01moL, 1.65g), heated to reflux for 1h, cooled to room temperature, added 2-methyl-3-methoxycarbonylpropionyl chloride (0.21moL, 34.4g), reacted at 70°C for 8h, concentrated under reduced pressure and recovered Solvent, the residue was poured into 800mL ice water containing 13ml of concentrated hydrochloric acid, left at room temperature for 2h, a light yellow precipitate was precipitated, filtered, and the precipitate was collected to obtain the crude product of 3-acetamidobenzoyl butyric acid methyl ester, which was weighed with 95% ethanol Crystallization gave 43.1 g of methyl 3-p-acetamidobenzoyl butyrate, yield 82%, melting point 212-213°C; 1HNMR (500MHz, DMSO-d6) δ1.23 (d, J=6.8Hz, 3H, CH3 ), 2...

Embodiment 2

[0048] Step ①: Dissolve acetanilide (0.2 mol, 27g) in a mixed solvent of 45ml carbon disulfide and 45ml N,N-dimethylformamide, stir at room temperature to obtain a colorless transparent solution, and add anhydrous trichloro Aluminum chloride (0.4 mol, 52.4g) and potassium iodide (0.015 mol, 2.48g), heated to reflux for 1h, cooled to room temperature, added 2-methyl-3-methoxycarbonyl propionyl chloride (0.21 mol, 34.4g), at 70 React at ℃ for 8 hours, concentrate under reduced pressure to recover the solvent, pour the residue into 800mL ice water containing 13ml of concentrated hydrochloric acid, leave it at room temperature for 2h, a light yellow precipitate precipitates, filter, collect the precipitate to obtain 3-acetamidobenzoyl butyric acid methyl ester The crude product was recrystallized from 95% ethanol to obtain 46.3 g of methyl 3-p-acetamidobenzoyl butyrate, with a yield of 88% and a melting point of 212-213°C.

[0049] Step ②: Mix the 3-p-acetamidobenzoyl butyric acid...

Embodiment 3

[0055] Step ①: Dissolve acetanilide (0.2 mol, 27g) in a mixed solvent of 45ml carbon disulfide and 45ml N,N-dimethylformamide, stir at room temperature to obtain a colorless transparent solution, and add anhydrous trichloro Aluminum chloride (0.4 mol, 52.4g) and potassium iodide (0.02 mol, 3.3g), heated to reflux for 1h, cooled to room temperature, added 2-methyl-3-methoxycarbonyl propionyl chloride (0.21 mol, 34.4g), at 70 React at ℃ for 8 hours, concentrate under reduced pressure to recover the solvent, pour the residue into 800mL ice water containing 13ml of concentrated hydrochloric acid, leave it at room temperature for 2h, a light yellow precipitate precipitates, filter, collect the precipitate to obtain 3-acetamidobenzoyl butyric acid methyl ester The crude product was recrystallized from 95% ethanol to obtain 46.3 g of methyl 3-p-acetamidobenzoyl butyrate, with a yield of 88% and a melting point of 212-213°C.

[0056] Step ②: Mix the 3-p-acetamidobenzoyl butyric acid m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com