Preparation method and application of high temperature resistant solid polymer electrolyte

A solid polymer and electrolyte technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of not completely solving the safety problems of liquid electrolyte, avoiding the use of electrolyte, and low ionic conductivity, etc. The effect of large-scale production, improvement of chain segment motion ability and conductivity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of polymer electrolyte precursor solution: 1,4-butanediol diacrylate, LiN(CF 3 SO 2 ) 2, 1,4-butanediol diglycidyl ether, and benzoyl peroxide are mixed according to a mass ratio of 5:1:5:0.02 and then stirred and mixed evenly at room temperature.

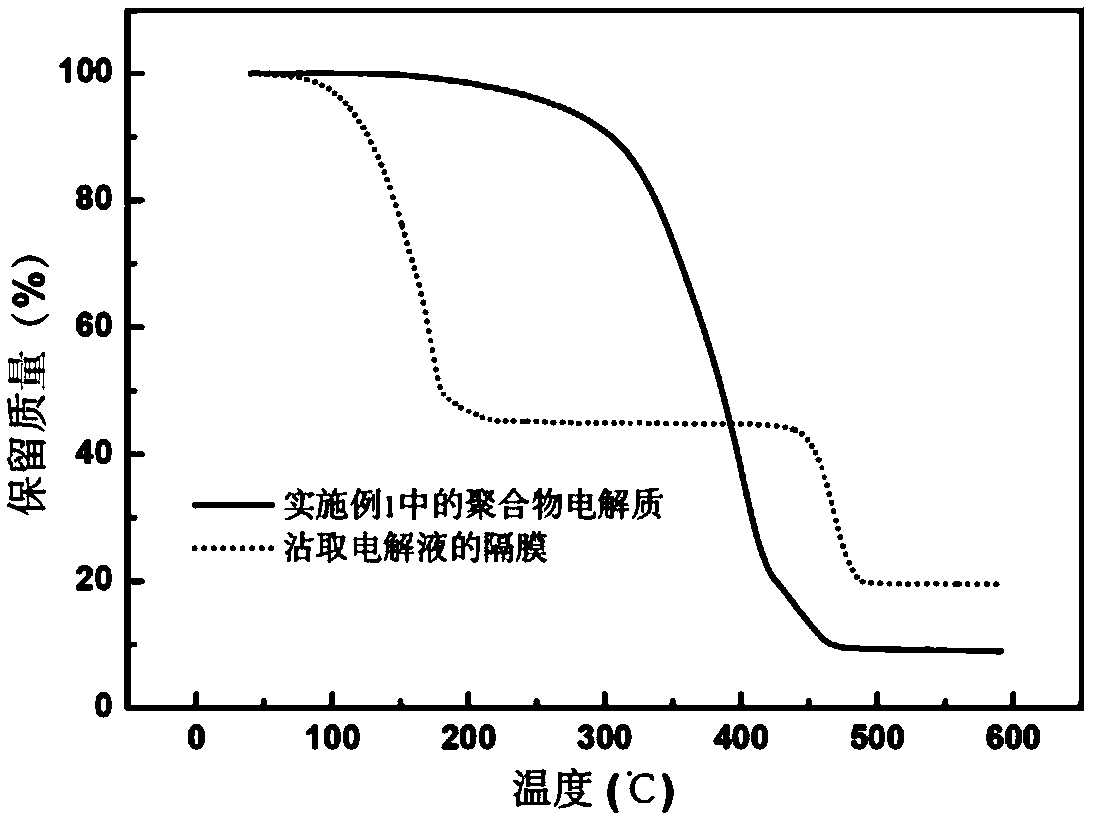

[0029] (2) Preparation of solid polymer electrolyte: the precursor solution obtained in step 1 was evenly coated on the polytetrafluoroethylene substrate at a ratio of 50 microliters per square centimeter, and thermally polymerized in an oven at 200° C. for 3 hours.

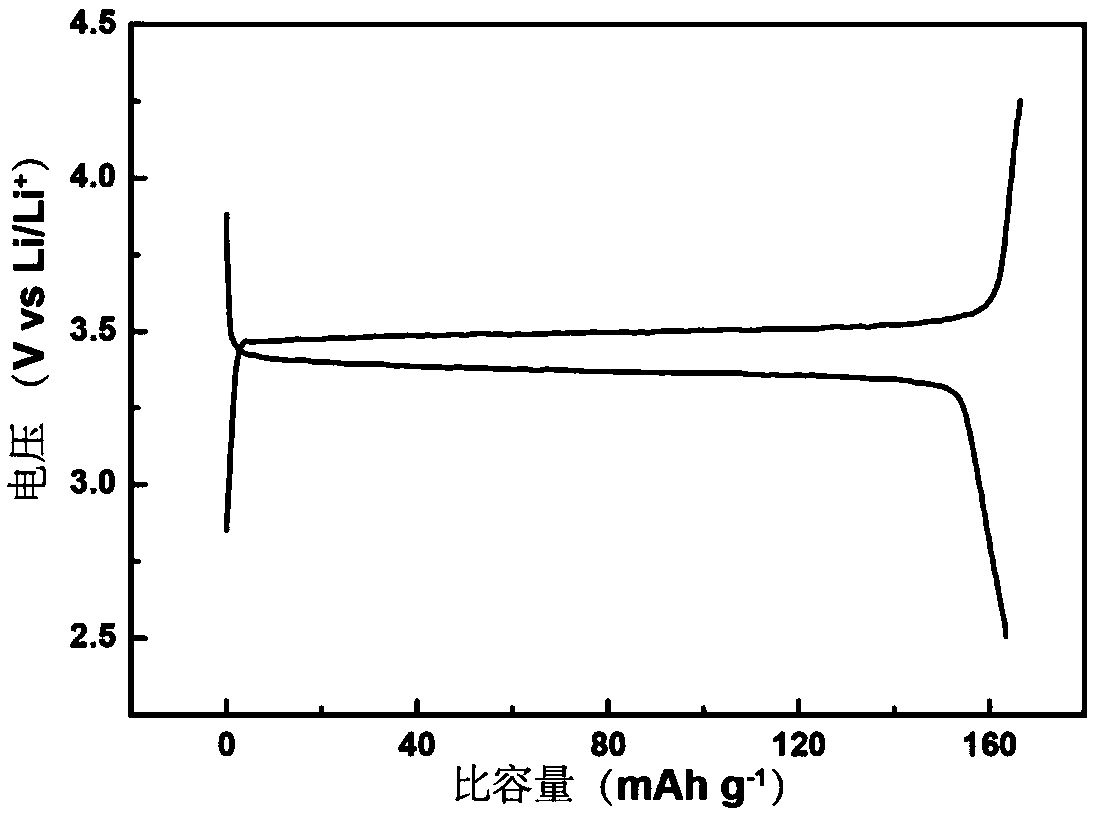

[0030] (3) Preparation of lithium iron phosphate cathode material: mix lithium iron phosphate, the polymer precursor obtained in step 1, conductive carbon black, and polyvinylidene chloride according to the mass ratio of 7:1:1:1, and then add N-methyl Pyrrolidone is made into a uniform slurry, which is evenly coated on an aluminum foil current collector, dried in a vacuum, and sliced to obtain a working positive electrode. (4) Assembly of m...

Embodiment 2

[0035] Except that thermal initiator benzoyl peroxide is changed into photoinitiator 1-hydroxycyclohexyl phenyl ketone in embodiment 1 (1), and thermal polymerization is changed into photopolymerization, at a distance of 2 kilowatts of ultraviolet lamps 10 The centimeter position was polymerized for 30 minutes. Other conditions are exactly the same, and the test performance is listed in Table 1.

Embodiment 3

[0037] Except changing thermal initiator in embodiment 1 (1) into microwave initiator azobisisobutyronitrile, thermal polymerization is changed into microwave polymerization, at 10GHz, 1000w power polymerization 20min. , other conditions are exactly the same, the test performance is listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com