Aqueous phase preparation method of red light silver sulfide quantum dots

A water-phase preparation and silver sulfide technology, which is applied in the interdisciplinary research field of materials science and photonics, can solve the problem of weak light absorption and scattering, difficulty in obtaining imaging results with high signal-to-noise ratio, biological toxicity and environmental pollution limiting the application of cadmium-based quantum dots and other issues, to achieve good biocompatibility and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

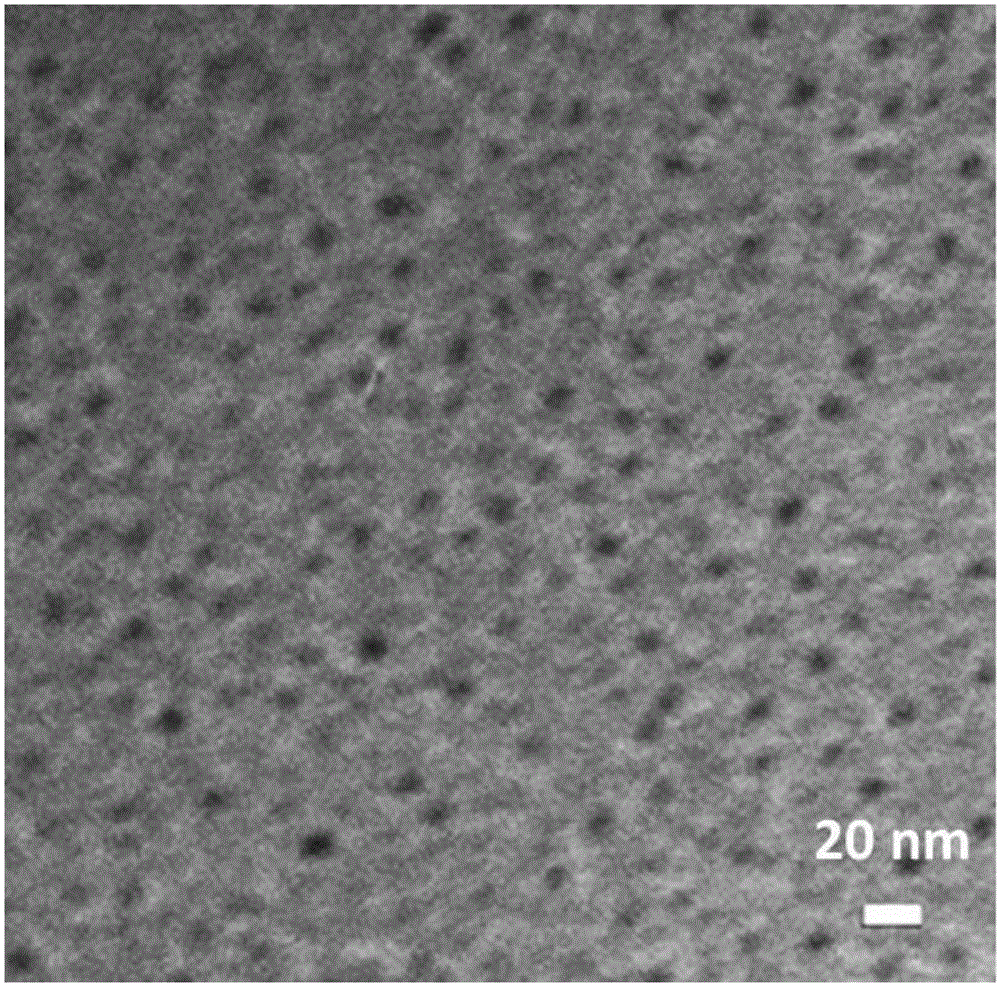

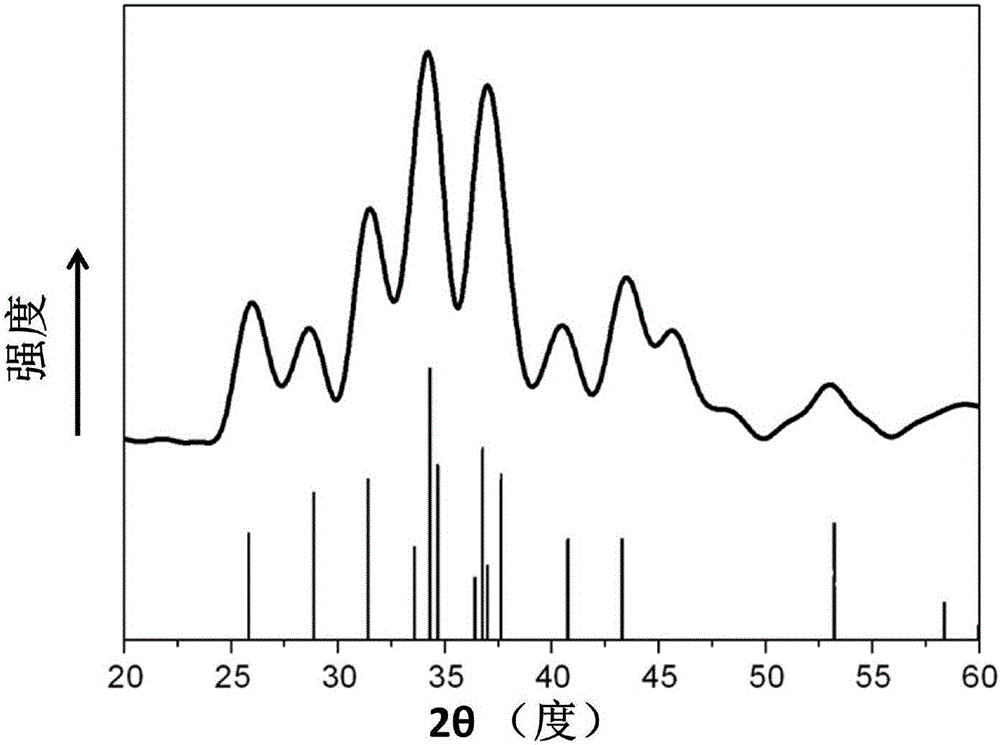

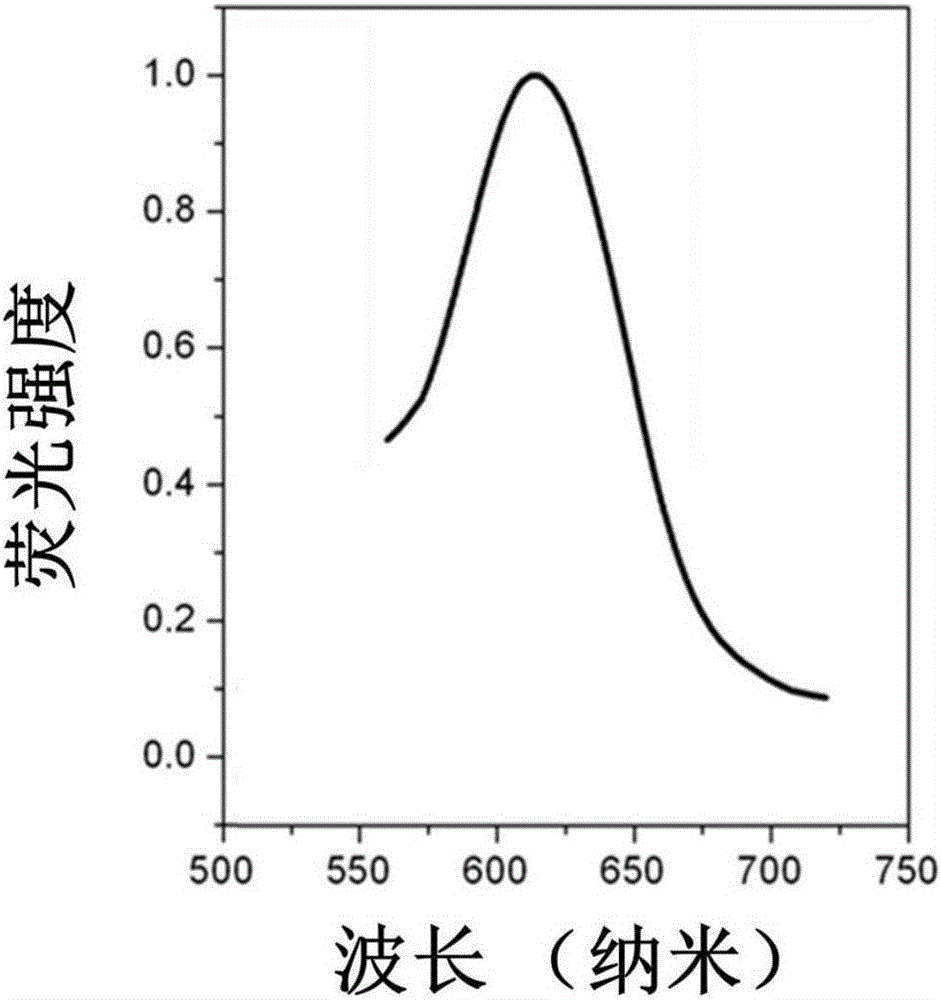

[0023] The preparation mass concentration is 10 milliliters of deoxyribonucleic acid aqueous solution of 1wt%, and in the gained solution, dripping the sodium hydroxide aqueous solution that mass fraction is 25wt% to mixed solution pH is 12 and stirs for 30 minutes; Add 10 milliliters of molar concentration 0.1mmol / L silver nitrate aqueous solution; after stirring the mixed solution for 5 minutes, add 5 milliliters of sodium sulfide aqueous solution with a molar concentration of 0.1mmol / L, continue stirring the solution to allow it to react for 30 minutes; centrifuge the mixed solution to obtain silver sulfide Solid precipitation; the obtained precipitation was placed in air and dried at room temperature to obtain silver sulfide quantum dot solid powder. The obtained silver sulfide quantum dots were characterized by composition, morphology and spectrum. Specific characterization means include transmission electron microscope, X-ray diffraction, and fluorescence spectrometer. T...

Embodiment 2

[0025] The preparation mass concentration is 10 milliliters of deoxyribonucleic acid aqueous solution of 3wt%, and in the gained solution, dripping the sodium hydroxide aqueous solution of 50wt% to the mixed solution pH is 14 and stirs for 60 minutes; Add 10 milliliters of molar concentration 1mmol / L silver nitrate aqueous solution; after stirring the mixed solution for 10 minutes, add 20 milliliters of sodium sulfide aqueous solution with a molar concentration of 1mmol / L, and continue to stir the solution to allow it to react for 60 minutes; centrifuge the mixed solution to obtain a silver sulfide solid precipitate The resulting precipitate is placed in the air and dried at room temperature to obtain a solid powder of silver sulfide quantum dots. The obtained silver sulfide quantum dots were characterized by composition, morphology and spectrum. Specific characterization means include transmission electron microscope, X-ray diffraction, and fluorescence spectrometer. Range 50...

Embodiment 3

[0027] The preparation mass concentration is 10 milliliters of deoxyribonucleic acid aqueous solution of 2wt%, and in the gained solution, dripping the sodium hydroxide aqueous solution of 40wt% to the pH of mixed solution is 13 and stirs for 45 minutes; Add 10 milliliters of molar concentration 0.5mmol / L silver nitrate aqueous solution; after stirring the mixed solution for 8 minutes, add 10 ml of sodium sulfide aqueous solution with a molar concentration of 0.5mmol / L, and continue stirring the solution to allow it to react for 45 minutes; centrifuge the mixed solution to obtain silver sulfide Solid precipitation; the obtained precipitation was placed in air and dried at room temperature to obtain silver sulfide quantum dot solid powder. The obtained silver sulfide quantum dots were characterized by composition, morphology and spectrum. Specific characterization means include transmission electron microscope, X-ray diffraction, and fluorescence spectrometer. The wavelength ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com