Process for preparing high-purity xylooligosaccharide

A xylo-oligosaccharide, high-purity technology, applied in biochemical equipment and methods, microorganisms, fermentation and other directions, can solve problems such as reducing product yield, and achieve the effects of reducing energy consumption, good moisture absorption resistance and light color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

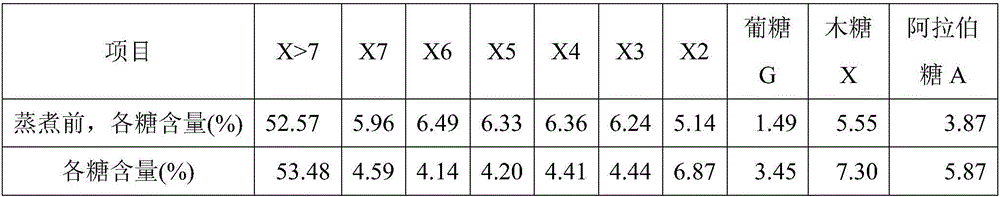

Embodiment 1

[0057] Crush the corncobs to about 20 meshes, adjust the slurry according to the solid-to-liquid ratio of 1:10, and pass through NH 3 Soak to pH 9.0 at 50°C for 24 hours, drain the pipe filter, and use the filtrate to soak the next batch of materials. After adding phosphoric acid to adjust the pH to 3.5, feed the materials directly into the horizontal tube continuous steamer, cook at 0.55MPa for 90 minutes, and release the pressure. into the enzymatic tank. After spraying, when the temperature drops to 60-65°C, add xylanase and dextranase complex, the enzyme activity ratio is 20-5:1, the amount of xylanase added is 5IU / g, and the enzyme is hydrolyzed at 40-60°C After 4 hours, lower the temperature to 37° C., inoculate Pichia stipitis CICC1960 and ferment for 36 hours. When the glucose concentration is less than 0.5%, raise the temperature to 80-100° C. to kill the enzyme. According to the conventional method including activated carbon decolorization and ion exchange resin rem...

Embodiment 2

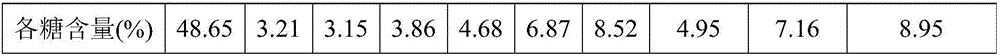

[0071] After the corn cob is crushed, mix it with a sodium hydroxide solution with a mass concentration of 0.05% in a mass ratio of 1:7 to pH 10, heat up to 60 degrees Celsius and keep it warm for 30 minutes, filter out the liquid; wash it with water until the pH value is neutral; mix with process water Mix according to the mass ratio of 1:3, add corncob dry weight percentage of 0.7% acetic acid, steam explosion treatment, treatment pressure 1.5MPa, time 120s; xylose content in the steam explosion liquid is 5.85%, when the temperature is reduced to 60~ Add xylanase and dextranase complex at 65°C, the enzyme activity ratio is 20-5:1, the amount of xylanase added is 8IU / g, and the temperature is lowered to 37 after enzymolysis at 40-60°C for 4 hours. °C, inoculate Torulopsis albicans (CICC31239) or Candida parapsilosis CICC31239 and ferment for 72 hours, and when the glucose concentration is ≤0.5%, heat up to 80-100 °C to inactivate the enzyme. Add 0.8g xylanase composition to c...

Embodiment 3

[0084] Crush the corncobs to about 20 meshes, adjust the slurry according to the solid-to-liquid ratio of 1:10, and pass through NH 3 Soak to pH 9.0 at 50°C for 24 hours, drain the pipe filter, and use the filtrate to soak the next batch of materials. After adding phosphoric acid to adjust the pH to 3.5, feed the materials directly into the horizontal tube continuous steamer, cook at 0.55MPa for 90 minutes, and release the pressure. into the enzymatic tank. After spraying, when the temperature drops to 60-65°C, add xylanase and dextranase complex, the enzyme activity ratio is 20-5:1, the amount of xylanase added is 5IU / g, and the enzyme is hydrolyzed at 40-60°C After 4 hours, lower the temperature to 37°C, inoculate Pichia stipitis CICC1960 and Candida parapsilosis CICC1257, the inoculum amount is 1% (v / v), and inoculate 1% (v / v) Torulopsis CICC31239 after 16 hours of fermentation After 20 hours of fermentation, when the glucose concentration is less than 0.5%, the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com