Hierarchical-structure MnOx/TiO2 nanofiber catalyst for acetone oxidation and preparation method of hierarchical-structure MnOx/TiO2 nanofiber catalyst

A nanofiber, hierarchical structure technology, applied in the field of hierarchical structure MnOx/TiO2 nanofiber catalyst and its preparation, can solve problems such as limited application, and achieve the effects of abundant oxygen vacancies, good catalytic performance, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Weigh 2g of PVP and dissolve it in 32ml of absolute ethanol, add 2ml of acetic acid and 8ml of tetrabutyl titanate in sequence, and stir overnight with magnetic force to obtain a yellow transparent sol.

[0033] Step 2, using a 22G dispensing needle, electrospinning under the conditions of injection pump injection speed 1ml / h, voltage 15kV, receiving distance 12cm, drum rotation speed 50r / min, to obtain primary nanofibers.

[0034] In step 3, the nascent nanofibers are put into a muffle furnace, heated to 500° C. at a heating rate of 2.5° C. / min and kept for 3 hours to obtain a titania nanofiber carrier.

[0035] Step 4, configuring the precursor solution required for the hydrothermal reaction. Take by weighing 0.0147g manganese acetate tetrahydrate and 0.1682g hexamethylenetetramine and be dissolved in 40ml deionized water, obtain clear solution, add 0.5g PEG (polyethylene glycol), 0.3645g CTAB (16 Alkyltrimethylammonium bromide), and continued to stir for 1h ...

Embodiment 2

[0038] The preparation method is similar to that of Example 1, except that in step 4, 0.0588 g of manganese acetate tetrahydrate is weighed, and the concentration of manganese acetate in the precursor solution after dissolving in water is 6 mmol / L.

Embodiment 3

[0040] The preparation method is similar to that of Example 1, except that in step 4, 0.1471 g of manganese acetate tetrahydrate is weighed, and the concentration of manganese acetate in the precursor solution after being dissolved in water is 15 mmol / L.

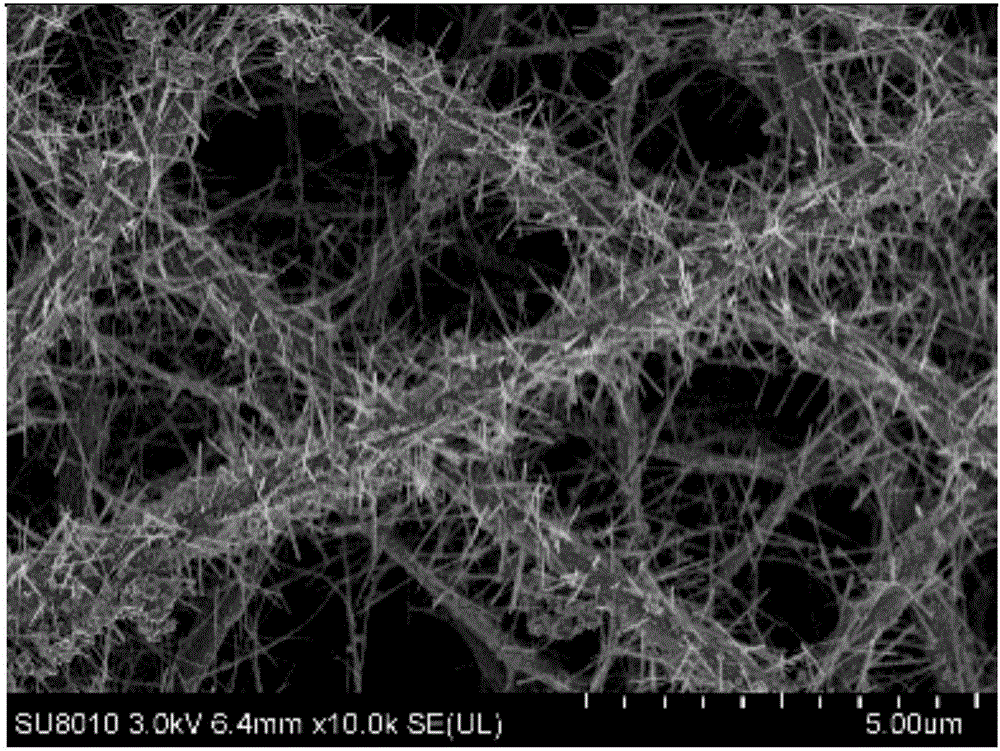

[0041] The MnO with hierarchical structure prepared in this embodiment x / TiO 2 SEM images of nanofibers are shown in figure 1 ,From figure 1 It can be seen that the primary TiO obtained by electrospinning 2 The diameter of nanofibers is 300-500nm, and they are interwoven with each other to form a network structure; after hydrothermal reaction, secondary MnO with a length of about 100nm is vertically grown on its surface x nanoneedles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com