Preparation method and application of sludge carbonization and modification magnetic nanometer material capable of activating persulfate to realize printing and dyeing wastewater treatment

A technology for activating persulfate and magnetic nanometers, applied in pyrolysis treatment of sludge, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problem of small specific surface area, difficulty in ensuring the characteristics of nanoparticles, and reduced catalytic efficiency, etc. problems, to achieve the effect of a wide range of sources, high stability and catalytic activity, and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

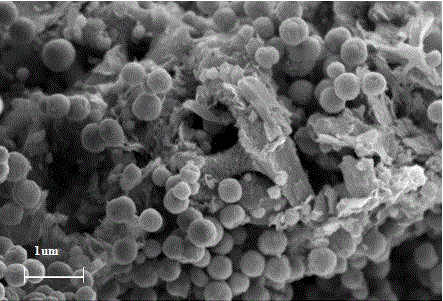

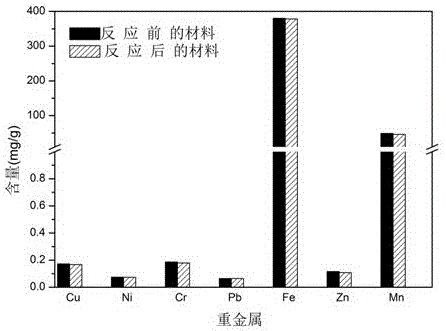

[0026] The preparation method of the sludge carbonization modified magnetic nano-material of the present embodiment comprises the following steps: (1) sludge pyrolysis treatment: put the remaining sludge taken from the sewage plant into a blast drying box, Dry at constant temperature for 48 hours, crush and pass through a 100-mesh sieve to obtain dry sludge. Get 10g of dry sludge and put it into 40mL of HNO with a mass fraction of 20%. 3 After stirring at room temperature for 24 hours, the activated sludge was centrifuged at a speed of 5000rpm and placed in a blast drying oven to dry at 105°C for 12 hours; the dried sludge was placed in a tubular resistance furnace , blow nitrogen at a flow rate of 100mL / min for 10min to remove the air in the tube. The pyrolysis step is to first raise the temperature to 700°C at a rate of 10°C / min, then cool down to 200°C at a rate of 10°C / min after staying for 60 minutes, and finally cool down to room temperature naturally. The cooled black...

Embodiment 2

[0030] This embodiment is a preparation method of sludge carbonization modified magnetic nanomaterials with different sludge activated carbon contents, including the following steps:

[0031] (1) sludge pyrolysis treatment is the same as step (1) in embodiment 1;

[0032] (2) Preparation of sludge carbonization modified magnetic nanomaterials: the raw material consumption of porous sludge activated carbon carbon powder described in step (1) is 0.4g, and all the other steps are the same as step (2) in Example 1;

[0033] (3) porous sludge activated carbon carbon powder raw material consumption described in step (1) is 0.8g, and other conditions are the same as (2);

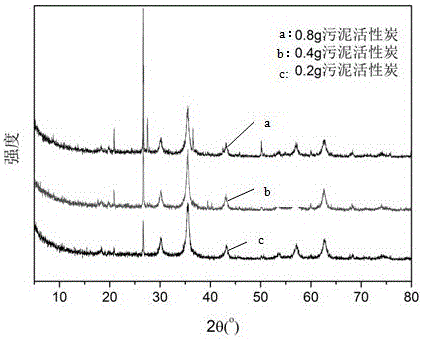

[0034] The X-ray crystal diffraction patterns (XRD) of the sludge carbonization modified magnetic nanomaterials obtained with different sludge activated carbon contents are as follows: figure 2 As shown, it can be seen from the figure that the crystal structure of the sample is good, the crystallinity is high, and ...

Embodiment 3

[0036] The application of sludge carbonization modified magnetic nanomaterials to activate persulfate to treat printing and dyeing wastewater in this embodiment includes the following steps:

[0037] (1) The preparation method of sludge carbonization modified magnetic nanomaterial is the same as step (1) and step (2) in the implementation case 1;

[0038] (2) Prepare 20 mg / L Orange G solution for later use, and use a 250 mL Erlenmeyer flask as the reactor. Add 100mL, 20mg / L orange G solution to the reactor, and add 0.02g of sludge carbonation modified magnetic nanomaterials to the reactor at the same time, and add 0.05g of Na 2 S 2 o 8 Place the Erlenmeyer flask in a shaker at 160pm, react at normal temperature (25°C), take samples every 5min, filter with a 0.22μm filter head and analyze at 478nm with a spectrophotometer;

[0039] (3) Do not add sludge carbonization modified magnetic nanomaterials in the reactor, other conditions are the same as (2);

[0040] (4) No solid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com