Treatment agent for petrochemical wastewater and preparation method of treatment agent

A technology for treating chemicals and petrochemical sewage, applied in water/sewage treatment, water/sludge/sewage treatment, sterilization/microdynamic water/sewage treatment, etc. Corrosion of equipment and pipelines, etc., to achieve the effect of long sterilization time, good sterilization effect and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

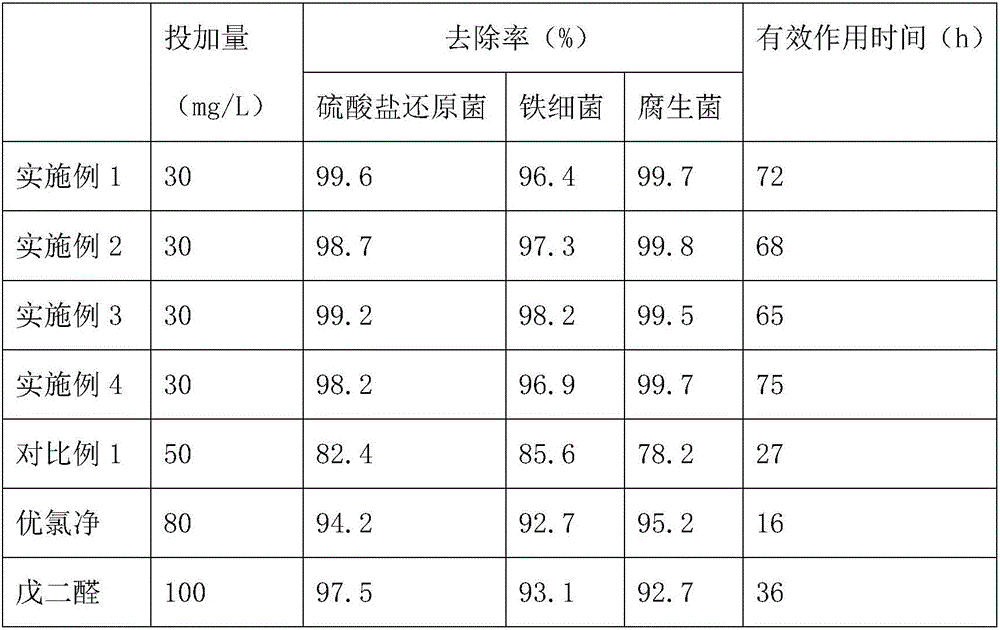

Examples

Embodiment 1

[0017] A petrochemical sewage treatment agent and a preparation method thereof, comprising the following raw materials in parts by weight: 2 parts of methylisothiazolinone, 4 parts of sucrose, 6 parts of melamine, 10 parts of bentonite, 3 parts of mirabilite, and 2 parts of aluminum sulfate , 2 parts of sodium silicate, 10 parts of lithopone, 5 parts of Sanhuang powder, 1.5 parts of Coptis chinensis, 3 parts of terrazzo vine and 0.5 part of Zhulingcao, sucrose is dissolved in 30% ethanol solution with chitosan , soaked at room temperature for 3 hours, filtered and washed with deionized water, then added to a sodium hydroxide solution with a mass fraction of 26%, stirred evenly, and stored in a freezer for 5 hours, then filtered and washed with deionized water at 50 obtained by drying at °C.

[0018] The specific steps of the preparation method for the petrochemical sewage treatment agent and its preparation method are as follows:

[0019] Step 1, decocting the vine and Juling...

Embodiment 2

[0024] A petrochemical sewage treatment agent and a preparation method thereof, comprising the following raw materials in parts by weight: 5 parts of methylisothiazolinone, 6 parts of sucrose, 8 parts of melamine, 12 parts of bentonite, 5 parts of mirabilite, and 4 parts of aluminum sulfate , 3 parts of sodium silicate, 13 parts of lithopone, 7 parts of sanhuang powder, 2.5 parts of Coptis chinensis, 5 parts of terrazzo vine and 1.5 parts of Zhulingcao, sucrose is dissolved in 38% ethanol solution with chitosan , soaked at room temperature for 4 hours, filtered and washed with deionized water, then added to a sodium hydroxide solution with a mass fraction of 32%, stirred evenly, and frozen for 6 hours, then filtered and washed with deionized water at 57 obtained by drying at °C.

[0025] The specific steps of the preparation method for the petrochemical sewage treatment agent and its preparation method are as follows:

[0026] Step 1, decocting the terrazzo and Julingcao at 1...

Embodiment 3

[0031] A petrochemical sewage treatment agent and a preparation method thereof, comprising the following raw materials in parts by weight: 8 parts of methylisothiazolinone, 7 parts of sucrose, 10 parts of melamine, 15 parts of bentonite, 7 parts of mirabilite, and 5.5 parts of aluminum sulfate , 4 parts of sodium silicate, 16 parts of lithopone, 10 parts of Sanhuang powder, 3 parts of Coptis chinensis, 7 parts of terrazzo vine and 2 parts of Zhulingcao, the sucrose is dissolved in 38% ethanol solution with chitosan , soaked at room temperature for 4 hours, filtered and washed with deionized water, then added to a sodium hydroxide solution with a mass fraction of 32%, stirred evenly, and frozen for 7 hours, then filtered and washed with deionized water at 58 obtained by drying at °C.

[0032] The specific steps of the preparation method for the petrochemical sewage treatment agent and its preparation method are as follows:

[0033] Step 1, decocting the terrazzo and Julingcao ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com