A kind of molybdenum/titanium/silver metal layered composite material for space and preparation method thereof

A composite material and metal layer technology, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of uncontrollable electroplating quality, weak coating, poor compactness, etc., and achieve good vacuum atomic oxygen resistance, Good weldability and high compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

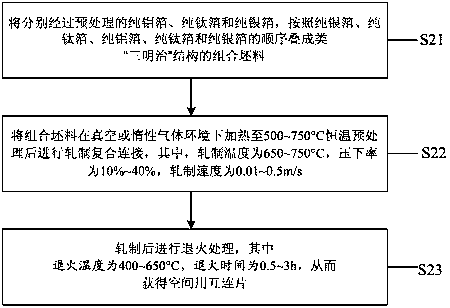

[0033] figure 2 It is a schematic flowchart of the steps of the preparation method of the molybdenum / titanium / silver metal layered composite material for space use provided by the embodiment of the present invention. refer to figure 2 , a method for preparing a molybdenum / titanium / silver metal layered composite material for space, comprising:

[0034] S21. Pretreated pure molybdenum foil, pure titanium foil and pure silver foil respectively, according to the pure silver foil, the pure titanium foil, the pure molybdenum foil, the pure titanium foil and the pure silver foil The sequence is stacked into a combined blank with a "sandwich" structure;

[0035] S22. Carry out rolling composite connection of the combined blanks in a vacuum or inert gas environment, wherein the rolling temperature is 650-750°C, the reduction rate is 10%-40%, and the rolling speed is 0.01-0.5m / s;

[0036] S23. After rolling the combined billet, further annealing treatment under an inert gas atmos...

Embodiment 1

[0041] In the molybdenum / titanium / silver metal layered composite material for space, the middle layer is a pure molybdenum foil with a thickness of 50 μm and a purity of 99.99%. The thickness of the welding layer of each layer is 20 μm, and the purity is 99.99% pure silver foil. The five layers are combined by rolling composite connection, and the Ag / Ti / Mo / Ti / Ag interface is combined by chemical metallurgy. The molybdenum / titanium / Silver metal layered composite material uses parallel resistance welding space gallium arsenide solar cells, the tensile strength of the solder joints is 6~8N, and the interface does not appear to fall off.

[0042] The operation of preparing molybdenum / titanium / silver metal layered composite materials for space is as follows: two pieces of silver foil with a thickness of 20 μm and two pieces of titanium foil with a thickness of 8 μm are respectively washed with isopropanol and semiconductor cleaning solution, namely 1# electronic cleaning solution. ...

Embodiment 2

[0044] In the molybdenum / titanium / silver metal layered composite material for space, the middle layer is a pure molybdenum foil with a thickness of 30 μm and a purity of 99.99%. The thickness of the welding layer of each layer is 20 μm, and the purity is 99.99% pure silver foil. The five layers are combined by rolling composite connection, and the Ag / Ti / Mo / Ti / Ag interface is combined by chemical metallurgy. The molybdenum / titanium / Silver metal layered composite material uses parallel resistance welding space gallium arsenide solar cells, the tensile strength of the solder joints is 6~8N, and the interface does not appear to fall off.

[0045] Two pieces of 20μm thick silver foil and two pieces of 6μm thick titanium foil were respectively used to remove oil stains on the surface of silver foil and titanium foil with isopropanol and semiconductor cleaning solution (1# electronic cleaning solution), and 25% hydrofluoric acid ( HF) aqueous solution to remove the oxide layer on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com