PELCL/polycaprolactone-REDV electrospun fiber film and preparation method

A technology of electrospun fiber and caprolactone, which is applied in the field of tissue engineering and biomedical materials, can solve the problems of increasing the cost of raw materials and reducing the activity of biologically active substances, and achieves good fiber morphology, good biological activity, and promotes the development of vascular endothelial cells. Effects of Adhesion and Growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the above-mentioned polyethylene glycol-b-poly(L-lactide-co-ε-caprolactone) (PELCL) / polyε-caprolactone-REDV electrospun microfiber membrane, is characterized in that Including the following process:

[0035] (1) Polyethylene glycol-b-poly(L-lactide-co-ε-caprolactone) (PELCL) and polyε-caprolactone-REDV, dissolved together in chloroform and N,N-dimethyl The electrospinning solution with a concentration of 100-200 mg / mL is formulated in a mixed solvent with a volume ratio of 4:1-8:1 of phenyl formamide, and the mass ratio of PELCL and polyε-caprolactone-REDV is (5-1 ):1;

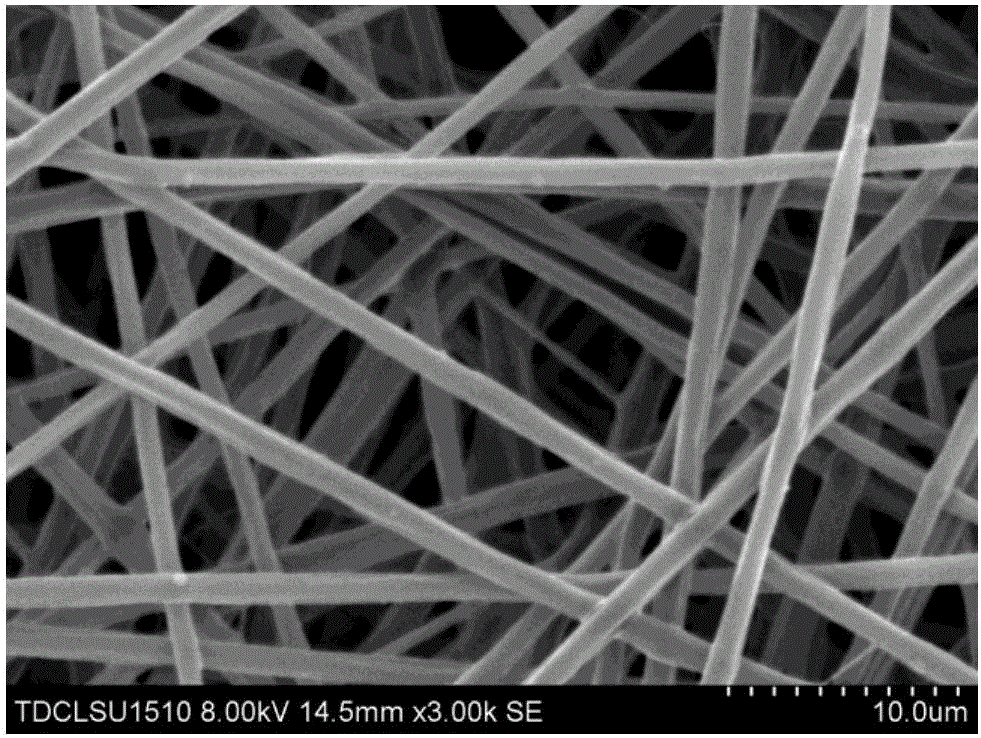

[0036] (2) Electrospinning the solution obtained in step (1), the electrospinning conditions are as follows: the flow rate of the solution is 0.02~0.10mL / h, the voltage of electrospinning is 12~20kV, and the receiving distance is 15~20cm, and 50~20cm is obtained. Electrospun fiber membrane with a thickness of 200 μm, that is, polyethylene glycol-b-poly(L-lactide-co-ε-caprolac...

Embodiment 1

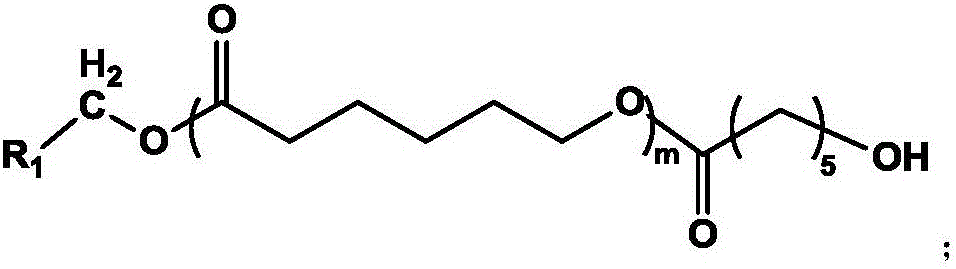

[0038] In a three-neck flask equipped with magnetic stirring, 3 g of polyε-caprolactone ( Two-terminal hydroxyl) was dissolved in 10mL of anhydrous dichloromethane, according to the molar ratio [two-terminal hydroxyl polyε-caprolactone] / [CDI]=1:2, add CDI 74.5mg, in N 2 Stir the reaction at room temperature for 24 hours, then add 0.52 g of hydroxyethyl acrylate and 0.1 g of catalyst 4-lutidine, stir and react for 48 hours at room temperature, the product is precipitated with excess methanol, and dried in vacuum for 24 hours to obtain white polyε - Caprolactone double bond modified product.

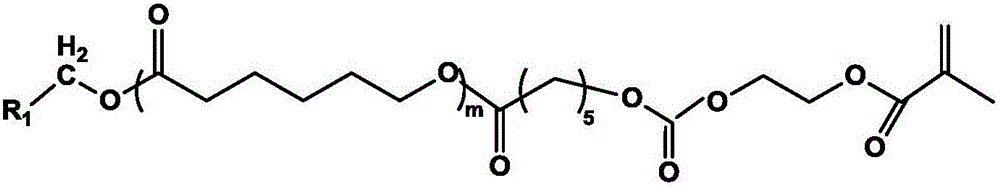

[0039] Dissolve 796 mg of the double bond modified product of polyε-caprolactone in 3 mL of dichloromethane solution. Add 40mg of REDV at 1:1, then add 8.4mg of photocatalyst 2,2-dimethoxy-2-phenylacetophenone, stir evenly at room temperature, place in a circular petri dish, and irradiate in 365nm UV for 10min , the product was precipitated with ethanol to obtain polyε-caprolactone-REDV...

Embodiment 2

[0042] In a three-neck flask equipped with magnetic stirring, 5 g of polyε-caprolactone ( Two-terminal hydroxyl) was dissolved in 10mL of anhydrous dichloromethane, according to the molar ratio [two-terminal hydroxyl polyε-caprolactone] / [CDI]=1:2, add CDI 32.4mg, in N 2 Stir the reaction at room temperature for 24 hours, then add 0.60 g of hydroxyethyl acrylate and 0.11 g of catalyst 4-lutidine, stir and react at room temperature for 60 hours, the product is precipitated with excess methanol, and dried in vacuum for 24 hours to obtain white polyε - Caprolactone double bond modified product.

[0043] Dissolve 600 mg of the double bond modified product of polyε-caprolactone in 3 mL of dichloromethane solution. Add REDV-SH 15mg at 1:1, then add 3.1mg of photocatalyst 2,2-dimethoxy-2-phenylacetophenone, stir evenly at room temperature, place in a circular petri dish, in 365nm UV After irradiating for 15 minutes, the product was precipitated with ethanol to obtain polyε-caprolac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com