Preparation method of enhanced aluminum calcium chloride crystal

A calcium aluminum chloride, enhanced technology, used in chemical instruments and methods, water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of high property and other problems, so as to achieve the effects of non-toxicity in the preparation process, environmental protection in the preparation process, and improvement of the purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

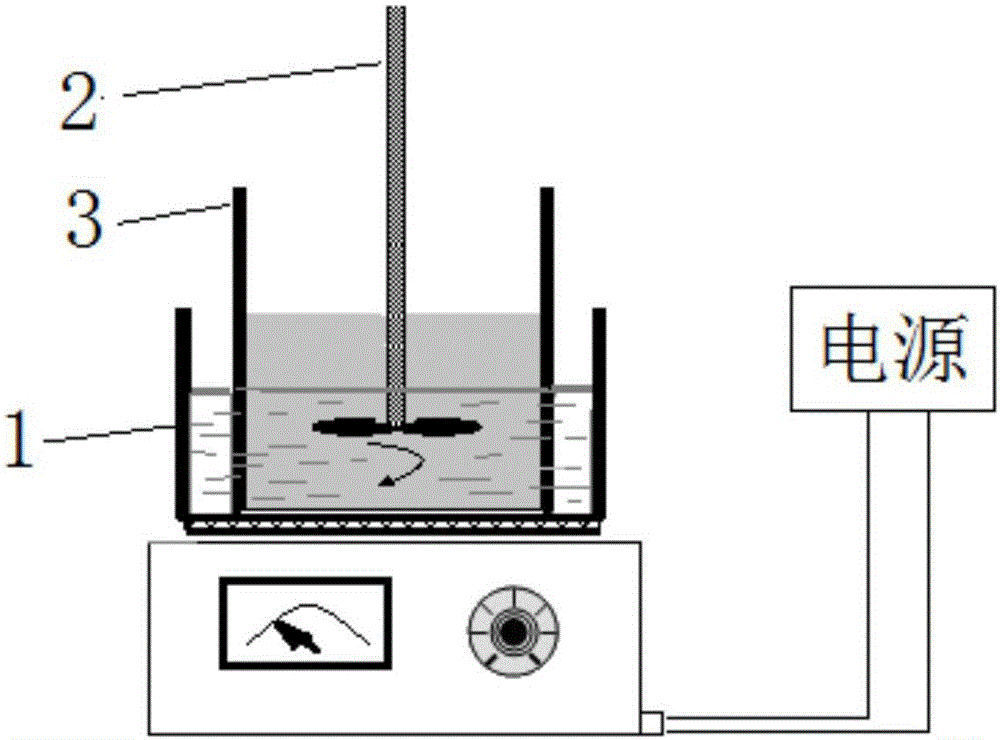

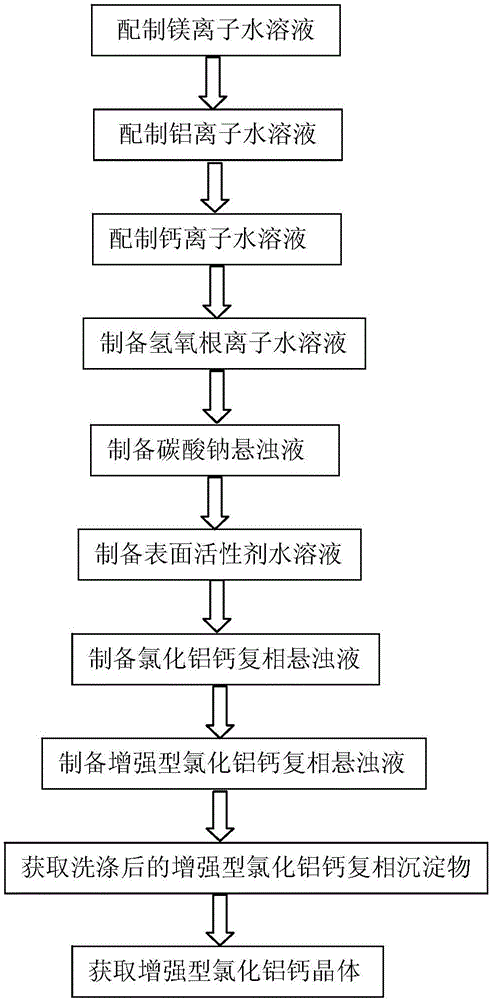

Method used

Image

Examples

Embodiment 1

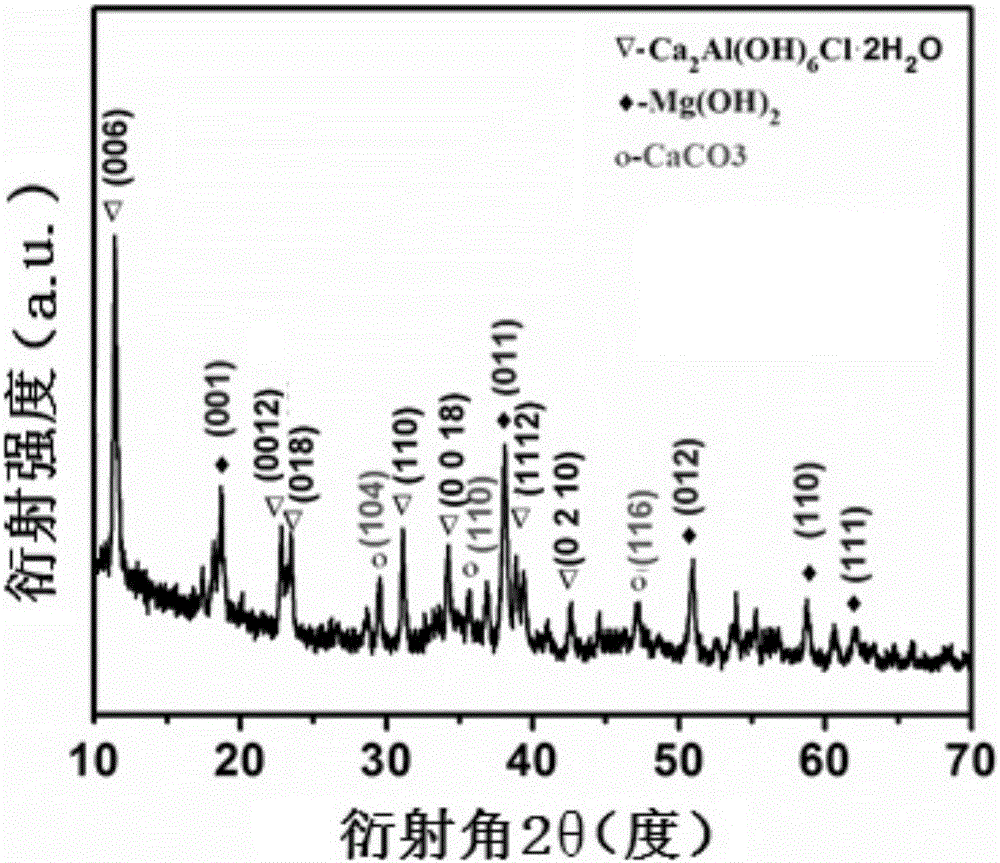

[0058] Example 1, preparing reinforced aluminum calcium chloride crystals containing 23% of magnesium hydroxide, 7.3% of calcium carbonate and 69.7% of aluminum calcium chloride in the multiphase crystal.

[0059] The first step is to prepare magnesium ion aqueous solution.

[0060] 1.1) 3.8 grams of MgCl 2 Dissolve it in 500ml deionized water to prepare a magnesium ion aqueous solution with a concentration of 0.08mol / L, and use a stainless steel vessel to hold the solution;

[0061] 1.2) filter to remove impurities in the magnesium ion aqueous solution:

[0062] 1.21) Put the funnel on the instrument support, put the clean beaker under the funnel, and fold the filter paper on the funnel;

[0063] 1.22) Pour the magnesium ion aqueous solution on the filter paper at a speed of 55 ml / min to obtain the magnesium ion aqueous solution after removing impurities.

[0064] The second step is to prepare aluminum ion aqueous solution.

[0065] 2.1) 31.4 grams of AlCl 3 ·6H 2 Disso...

Embodiment 2

[0091] Example 2, preparing reinforced calcium aluminum chloride crystals containing 28.9% of magnesium hydroxide, 53.4% of calcium aluminum chloride and 17.7% of calcium carbonate in the multi-phase crystal.

[0092] Step 1, preparing magnesium ion aqueous solution.

[0093] 1a) 10.7 grams of MgCl 2 Dissolve it in 500ml deionized water to prepare a magnesium ion aqueous solution with a concentration of 0.226mol / L, and use a stainless steel vessel to hold the solution;

[0094] 1b) filter to remove impurities in the magnesium ion aqueous solution:

[0095] The specific implementation of this step is the same as step 1.2) of Embodiment 1.

[0096] Step 2, prepare aluminum ion aqueous solution.

[0097] 2a) 49.13 grams of AlCl 3 ·6H 2 O was dissolved in 500ml deionized water to prepare an aluminum ion aqueous solution with a concentration of 0.407mol / L, and the solution was contained in a stainless steel vessel;

[0098] 2b) filter to remove impurities in the aluminum io...

Embodiment 3

[0121] Example 3, preparation of reinforced aluminum calcium chloride crystals containing 25.1% magnesium hydroxide, 60.8% aluminum calcium chloride and 14.1% calcium carbonate in the multiphase crystal.

[0122] Step A, preparing magnesium ion aqueous solution.

[0123] A1) 38.95 grams of MgCl 2 Dissolve it in 500ml deionized water to prepare a magnesium ion aqueous solution with a concentration of 0.82mol / L, and use a stainless steel container to hold the solution;

[0124] A2) filter to remove impurities in the magnesium ion aqueous solution:

[0125] The specific implementation of this step is the same as step 1.2) of Embodiment 1.

[0126] Step B, prepare aluminum ion aqueous solution.

[0127] B1) 67.62 grams of AlCl 3 ·6H 2 O was dissolved in 500ml deionized water to prepare an aluminum ion aqueous solution with a concentration of 0.56mol / L, and the solution was contained in a stainless steel container;

[0128] B2) filter to remove impurities in the aluminum ion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com