A kind of preparation method of l-prolinol

A technology of prolinol and pyroglutamic acid, which is applied in the field of L-prolinol preparation, can solve the problems of high price of raw material L-proline and high production cost, etc., and is suitable for large-scale industrial production, The effect of short process route and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

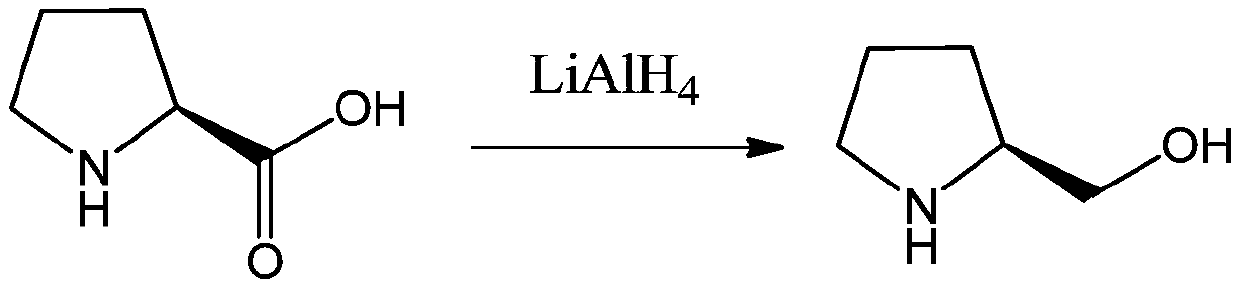

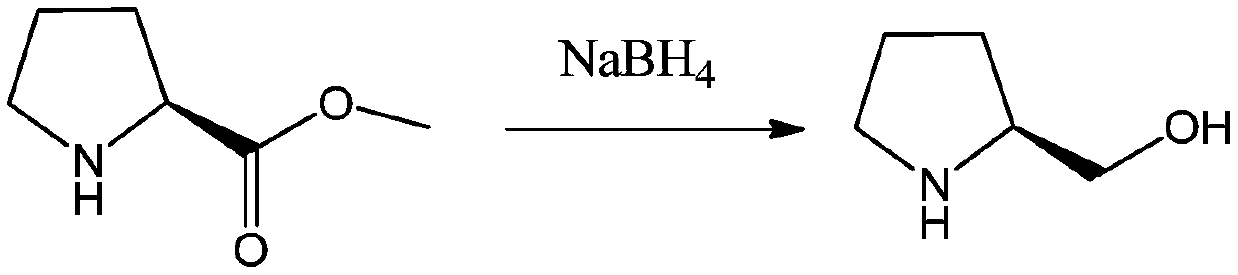

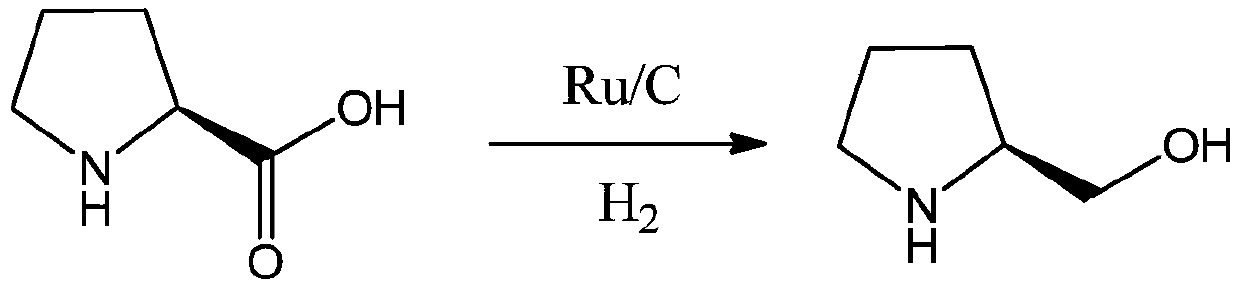

Method used

Image

Examples

Embodiment 1

[0055] (1) Preparation of molybdenum atom modified ruthenium carbon catalyst

[0056] Weigh 47.26g of activated carbon powder and disperse it in 200mL of deionized water; weigh 6.723g of ruthenium chloride trihydrate and dissolve it in 100mL of deionized water; under stirring conditions, mix the two and absorb for 1 hour; weigh 1.911g of molybdic acid Ammonium solid ((NH 4 ) 6 Mo 7 o 24 4H 2 (0), be dissolved in 50mL deionized water, gradually add in the above-mentioned gac solution under stirring condition; After stirring and absorbing for 1 hour, add sodium borohydride aqueous solution (1.2g sodium borohydride is dissolved in 100mL deionized water) gradually, react 1 at room temperature Hours later, filter with suction, wash 5 times with deionized water to near neutrality, and dry in an oven at 80° C. for 12 hours to obtain a molybdenum atom-modified ruthenium carbon catalyst, wherein the mass percentage of ruthenium is 5 wt%, and the mass percentage of molybdenum The c...

Embodiment 2

[0063] Preparation of L-prolinol

[0064] In a 2L autoclave, add 400g of L-pyroglutamic acid, 380ml of acetic acid, and 1000ml of water, and add the molybdenum atom-modified ruthenium carbon catalyst prepared in Example 1 (1) (ruthenium content: 5wt%, molybdenum content: 2wt%) 60 g, reacted for 18 hours under the condition that the hydrogen pressure was 7.5 MPa and the temperature was 105°C. Cool down to room temperature, release the pressure, and filter. The filter cake ruthenium carbon sleeve was used for the next reaction, and the filtrate was concentrated under reduced pressure to obtain about 450 g of L-prolinol crude product. The crude product was rectified to obtain 292 g of L-prolinol with a purity of 99.4% (GC), and a yield of 91%. The obtained product is consistent with the reference substance (GC analysis).

Embodiment 3

[0066] Preparation of L-prolinol

[0067] In a 20L there-necked flask, add 4kg of L-pyroglutamic acid, 4L of acetic acid, and 10L of water, stir and dissolve, add the molybdenum atom-modified ruthenium carbon catalyst prepared in Example 1 (1) (ruthenium content: 5wt%, molybdenum content: 2wt%) 600g. Under stirring, vacuum suction into the 20L autoclave. Under the conditions of hydrogen pressure of 8 MPa and temperature of 110° C., the reaction was carried out for 20 hours. Cool down to room temperature, release the pressure, and filter. The filter cake ruthenium carbon sleeve was used for the next reaction, and the filtrate was concentrated under reduced pressure to obtain about 4.2 kg of L-prolinol crude product. The crude product was rectified to obtain 2.9kg of L-prolinol with a purity of 99.3% (GC), and a yield of 90%. The obtained product is consistent with the reference substance (GC analysis).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com