Etching agent for displaying low alloy wear-resistant steel original austenite grain boundary and application of etching agent

An austenite grain boundary, wear-resistant steel technology, applied in the preparation of test samples, etc., can solve the problems of cumbersome solutions, inconvenient operation, and many types of solutions, and achieve the effects of short erosion time, simple operation, and simple production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

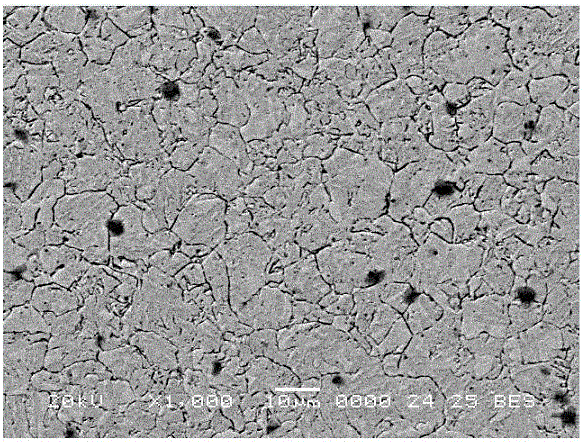

Image

Examples

Embodiment Construction

[0023] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiment:

[0024] The chemical composition of low alloy wear-resistant steel is: C:0.287%, Si:0.569%, Mn:1.028%, Cr:0.871%, Mo:0.314%, Cu:0.05%, Re:0.10%, P<0.025%, S<0.025%, the rest is Fe and unavoidable impurities.

[0025] The low-alloy wear-resistant steel is melted in a 1t acid induction furnace. The metal charge is pig iron for steelmaking, recycled carbon steel, ferrosilicon, ferrochrome, ferromolybdenum, scrap copper, rare earth, etc., and the ferroalloy is crushed and added. After smelting, the lost foam casting is adopted, and the pouring temperature is 1560-1600 ℃, and it is cast into a 15mm x 15mm x 60mm billet. After the casting is completed, when the casting is cooled to 800-900 ℃, the shell is removed and air-cooled to room temperature. Heat treatment process: heat the casting to 820-860°C for austenitization, heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com