Medicinal core substance and micro-capsule prepared by taking corn cob flour as core material

A technology of corn cob powder and capsule core, which is applied in the field of preparation of pharmaceutical preparations, can solve the problems of drug loss, insufficient cognition and research, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

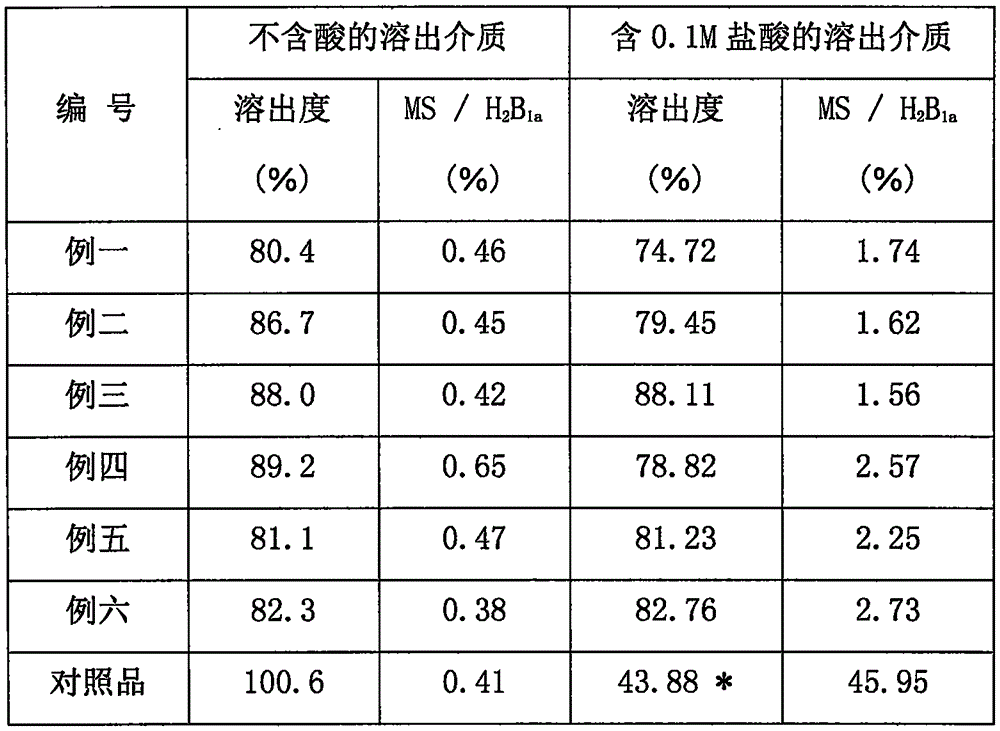

Embodiment 1

[0027] Embodiment 1, the preparation of enrofloxacin and its acidic salt or basic salt microcapsules: enrofloxacin is a kind of special quinolone antibacterial drug for animals, and it is mainly used in preventing and treating animal digestive system, respiratory system and urinary system System infection. Because enrofloxacin tastes bitter, has poor palatability, and is irritating to the stomach, most pigs refuse to eat enrofloxacin and its preparations without taste masking. Therefore, enrofloxacin administered orally must be coated Made into microcapsules, it is possible to feed as a premix, granule or tablet. Since enrofloxacin is insoluble in water and almost all organic solvents with good biocompatibility, the present invention adopts dissolving enrofloxacin in water to make an aqueous solution after salting, and selects an equivalent or slightly more Lactic acid, sodium hydroxide or sodium carbonate aqueous solution reacts with enrofloxacin to convert enrofloxacin into...

Embodiment 2

[0046] Embodiment 2, preparation of tilmicosin or tilmicosin phosphate or tilmicosin tartrate microcapsules

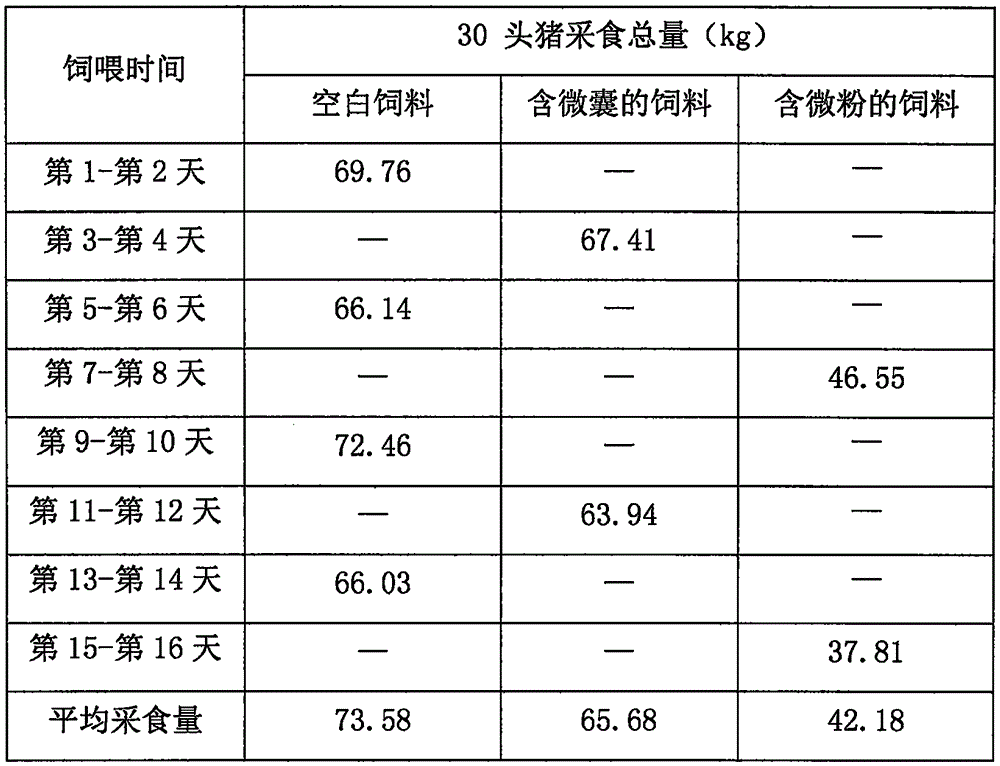

[0047] Tilmicosin and its salts are special antibiotics for livestock and poultry synthesized from tylosin. It has inhibitory effect on bacteria (Gram-positive bacteria and some Gram-negative bacteria), mycoplasma and spirochete, especially has strong antibacterial activity on Actinobacillus pleuropneumoniae, Pasteurella and mycoplasma in pigs. Because the taste of tilmicosin is very bitter, the tilmicosin in the tilmicosin preparation for oral administration must be coated and processed into microcapsules, so that pigs and other livestock can eat automatically.

[0048] The microcapsule preparation process is as follows:

[0049] 1. Preparation of tilmicosin phosphate microcapsules

[0050] (1) Preparation of capsule core: 3 kg of tilmicosin phosphate is stirred and dissolved with 9 liters of water, or 3 kg of tilmicosin is mixed with 9 liters of water and 0.4 liter...

Embodiment 3

[0058] Embodiment 3, the preparation of colistin sulfate microcapsule

[0059] Colistin sulfate is a narrow-spectrum antibiotic that mainly has a strong antibacterial effect on Gram-negative bacteria. The sensitive bacteria include Pseudomonas aeruginosa, Escherichia coli, Enterobacter, Klebsiella, Salmonella, and Shigella , Pasteurella and Vibrio, etc. Colistin sulfate is rarely absorbed orally, and oral preparations are mainly used to treat intestinal diseases caused by Gram-negative bacteria. Because colistin sulfate is bitter and acidic (pH value of 1% aqueous solution is 4.0-6.5), it is easy to react with alkaline substances in feed (such as vitamins, trace elements, etc.), therefore, it will cause colistin sulfate The potency of the element decreases, and the reaction produces water to increase the humidity of the feed, which is prone to deterioration. In addition, because colistin sulfate itself has hygroscopicity, it is not conducive to the storage of the product. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com