Modified environment-friendly flocculant for municipal sewage and preparation method of flocculant

A technology of urban sewage and flocculants, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of ineffective removal of refractory organic matter, etc., and is suitable for large-scale Industrial application, strong practicability and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

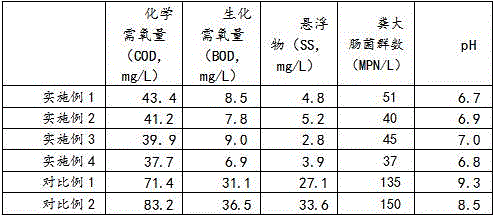

Examples

Embodiment 1

[0023] (1) Weigh 5 parts of biological sludge, 14 parts of straw powder, 5 parts of camphor leaves, 2 parts of apatite, 5 parts of lignin, 15 parts of expanded vermiculite powder, 2 parts of calamine powder, activated carbon fiber 4 parts of silk, 5 parts of hydroxyl acrylic resin, 10 parts of polyacrylate, 6 parts of dimethylethanolamine, 2 parts of disodium edetate, 4 parts of aluminum oxide, 3 parts of activated silica, anionic polypropylene 1 part amide, 3 parts sorbitol, 1 part stearamide, 4 parts sodium naphthenate, 2 parts vinyltrimethoxysilane, 1 part potassium permanganate;

[0024] (2) Wash the biological sludge, straw powder, camphor leaves, expanded vermiculite powder, and calamine powder, dry, cool to room temperature, and the drying temperature is 60°C;

[0025] (3) Add the dry matter of step (2), apatite, lignin, activated carbon fiber filaments, and disodium edetate into the ceramic furnace, slowly inject liquid nitrogen, and mechanically stir until the dry mat...

Embodiment 2

[0032] (1) Weigh 6 parts of biological sludge, 15 parts of straw powder, 8 parts of camphor leaves, 4 parts of apatite, 6 parts of lignin, 18 parts of expanded vermiculite powder, 3 parts of calamine powder, activated carbon fiber 5 parts of silk, 7 parts of hydroxyacrylic resin, 11 parts of polyacrylate, 7 parts of dimethylethanolamine, 3 parts of disodium edetate, 5 parts of aluminum oxide, 4 parts of activated silica, anionic polypropylene 2 parts of amide, 4 parts of sorbitol, 2 parts of stearamide, 5 parts of sodium stearate, 3 parts of 3-glycidyl propyl trimethoxysilane, 2 parts of magnesium fumarate;

[0033] (2) Wash the biological sludge, straw powder, camphor leaves, expanded vermiculite powder, and calamine powder, dry, cool to room temperature, and the drying temperature is 62°C;

[0034] (3) Add the dry matter of step (2), apatite, lignin, activated carbon fiber filaments, and disodium edetate into the ceramic furnace, slowly inject liquid nitrogen, and mechanical...

Embodiment 3

[0041] (1) Weigh 7 parts of biological sludge, 15 parts of straw powder, 10 parts of camphor leaves, 8 parts of apatite, 7 parts of lignin, 21 parts of expanded vermiculite powder, 3 parts of calamine powder, activated carbon fiber 8 parts of silk, 9 parts of hydroxyl acrylic resin, 12 parts of polyacrylate, 8 parts of dimethylethanolamine, 4 parts of disodium edetate, 8 parts of aluminum oxide, 5 parts of activated silica, anionic polypropylene 3 parts of amide, 5 parts of sorbitol, 3 parts of stearamide, 7 parts of magnesium benzoate, 4 parts of 3-methacrylpropyl triethoxysilane, 2 parts of sodium lauryl silicate;

[0042] (2) Wash the biological sludge, straw powder, camphor leaves, expanded vermiculite powder, and calamine powder, dry, cool to room temperature, and the drying temperature is 64°C;

[0043] (3) Add the dry matter of step (2), apatite, lignin, activated carbon fiber filaments, and disodium edetate into the ceramic furnace, slowly inject liquid nitrogen, and mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com