A low-pollution preparing method of glucose anisate and antibacterial applications of the glucose anisate

Anisic acid sugar ester, low pollution technology, applied in the directions of antibacterial drugs, sugar derivative preparation, chemical instruments and methods, etc., can solve the problems of unfavorable biological products, medical applications, complex reaction conditions, easy to pollute the environment, etc. The effect of less impurities, simple post-treatment and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Take 100 g of dried star anise fruit and grind it into 60-mesh powder, put it into a 2000 mL hard round-bottomed flask of volatile oil extractor, then add 800 mL of deionized water into the round-bottomed flask, soak for 1 h, Start to heat up to 90°C, and keep at 90°C for 2 hours, and the fennel oil enters the branch pipe of the volatile oil extractor along with part of the water vapor;

[0023] (2) Separate the fennel oil collected in the branch pipe of the volatile oil extractor to remove most of the water, then add 1 g of anhydrous magnesium sulfate to the fennel oil, let it stand for 20 min, heat the mixed solution to 50 °C, and Carry out suction filtration with Buchner funnel while hot to remove magnesium sulfate, collect filtrate, obtain fennel oil;

[0024] (3) Take 7.5 mL of fennel oil obtained in step (2), add it to a 50 mL round bottom flask, place the round bottom flask on a magnetic stirrer, and then add 1 g of ferric chloride to the round bottom flask, ...

Embodiment 2

[0031] The yields of anisic acid obtained in step (5) of Example 1 and sugar esters of anisic acid obtained in step (7) of Example 1 were calculated using formulas. The results showed that the yield of anisic acid obtained by hydrogen peroxide oxidation was as high as 91.3%, and the purity was 99.8%, and the product was white needle-like crystals; the yield of anisic acid sugar ester was 93%, and the purity was 99.5%.

Embodiment 3

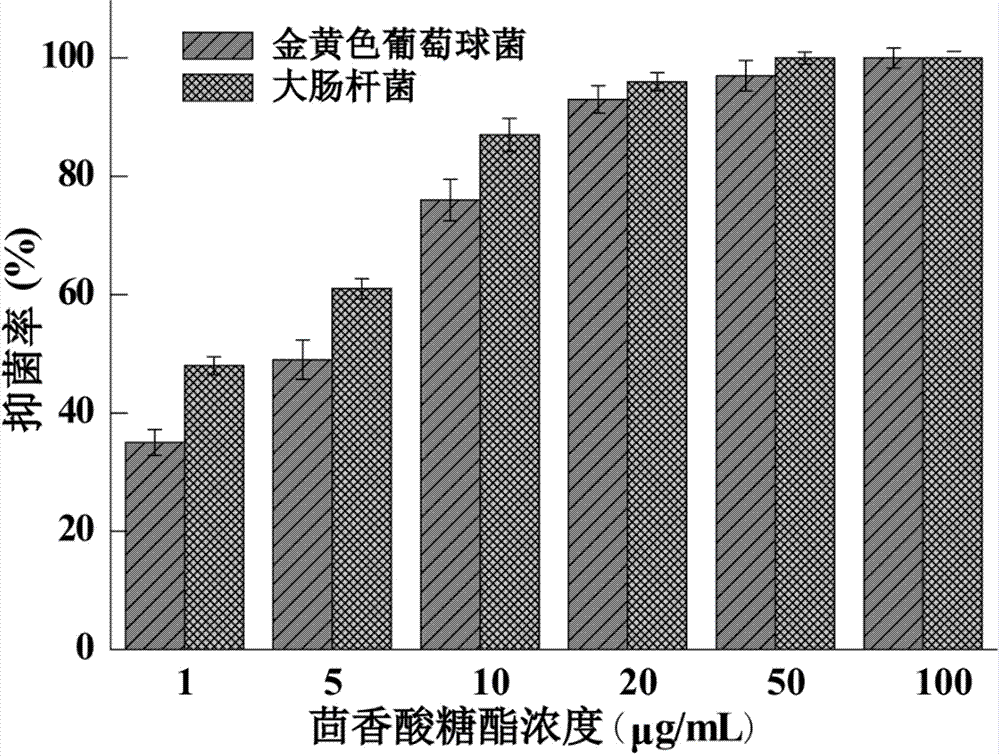

[0033] Take the anisic acid sugar ester obtained in step (7) of Example 1, add sterile physiological saline to configure different concentrations of anisic acid sugar ester suspension, and incubate with Staphylococcus aureus and Escherichia coli respectively, and use plate counting method to detect Antibacterial properties of sugar anisate:

[0034]In the experiment, 0.5 mL of Staphylococcus aureus bacterial liquid was placed in a conical flask filled with 50 mL of physiological saline, and 6 groups were set up, and then sugar anisate suspensions of different concentrations (1-100 μg / mL), and then put all the triangular flasks in a constant temperature incubator, and incubate at 37 °C for 12 h, then take out the suspension and dilute a certain gradient, then plate, count, and calculate the antibacterial rate of sugar anisate. Perform the same operation with 0.5 mL of E. coli liquid containing the same number of bacteria.

[0035] The experimental results showed that differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com