Propagation method of novel yeast for metabolism of pentose and hexose by co-fermentation

A technology of co-fermentation and six-carbon sugar, applied in microorganism-based methods, biochemical equipment and methods, fungi, etc., can solve the problems of aggravating production costs, low utilization rate, poor tolerance, etc. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

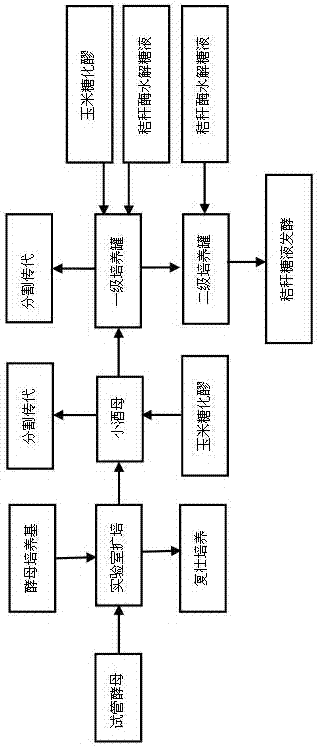

Image

Examples

Embodiment 1

[0023] A method for expanding the capacity of a novel five-hexose-metabolizing co-fermenting yeast, the composition of which comprises: Saccharomyces cerevisiae highly active yeast, whose Latin name is: strainV1, the new-type five-hexose-metabolizing co-fermenting yeast of the high activity yeast of Saccharomyces cerevisiae The expansion methods of bacteria are: (1) test tube yeast expansion; (2) primary cultivation; (3) secondary cultivation.

Embodiment 2

[0025] According to the expansion method of the new-type metabolizing five-hexose sugar co-fermentation yeast described in Example 1, the expansion method (1) The process of expanding the test tube yeast is: adding Saccharomyces cerevisiae highly active yeast into the activation solution, and the activation solution The composition is 2% glucose aqueous solution, the activation temperature is 35-40°C, and the activation time is 0.5-1.5 hours; after the activated yeast is expanded in a triangular flask, it is inserted into the small wine mother culture system, generally 3-5% inoculation amount, small wine mother After culturing, inoculate into the primary culture tank for further expansion.

Embodiment 3

[0027] According to the expansion method of the novel metabolizing five-hexose sugar co-fermentation yeast described in Example 1, the process of the expansion method (2) primary cultivation is: add 30-40% enzymatic hydrolysis to the primary expansion tank Fermentation liquid mixed with 60-70% corn saccharification mash to expand the culture. After the number of yeast cells reaches 150-250 million strains / ml, 80% of the yeast cells are divided into the secondary culture tank, and the primary culture tank is added according to the original proportion. Corn mash, enzymatic solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com