Preparation method of silica gel column supported meso-porous biochar solid sulfonic acid

A technology of biomass carbon and silica gel column, applied in the field of catalytic sucrose hydrolysis reaction, which can solve the problems of complex preparation process, low mass transfer efficiency and high raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

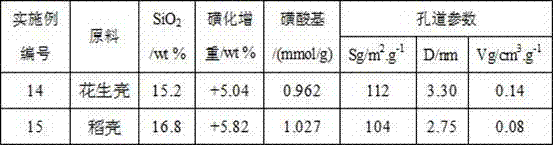

Examples

Embodiment 1

[0014] This example is used to illustrate the method for preparing silica gel pillared biomass carbon solid sulfonic acid by using bamboo powder and silica sol.

[0015] (1) Preparation of biochar material: Weigh 9 g of bamboo powder, put it in a tube furnace, heat up to 300 °C at a rate of 2 °C / min, and then stay for 3 h to obtain 3 g of carbon material (BC);

[0016] (2) Preparation of acidic silica sol: Add 200 mL of 0.05 M sodium silicate solution to 200 mL of 0.12 M oxalic acid solution in a stirred 35°C water bath, and adjust the pH between 3.0 and 3.5 , remove the sodium oxalate precipitate by filtration to obtain a 0.025 M silica sol solution;

[0017] (3) Carbon material pretreatment: Weigh 3 g of carbon material, add 30 mL of distilled water, and boil in a water bath at 100 °C for 3 hours to make the carbon material swell and fluffy, and cool to room temperature for later use;

[0018] (4) Preparation of silica gel-pillared mesoporous bamboo carbon material: Add 400...

Embodiment 2

[0026] Example 2: This example is used to illustrate the preparation method of silica gel pillared mesoporous solid sulfonic acid by dehydration and carbonization of concentrated sulfuric acid.

[0027] According to the method of Example 1 above, the difference is that the dehydration and carbonization method of concentrated sulfuric acid is used to prepare the BC material in step (1) of Example 1, and the subsequent steps are as in Steps (2), (3), (4) and (5) of Example 1 Steps are carried out.

[0028] The carbonization conditions in step (1) are described as follows: In a 100mL reaction bottle, add 6g of bamboo powder and 48mL of concentrated sulfuric acid, heat to 80°C, stir for 3 hours, and wash with water repeatedly after cooling until the filtrate is colorless and neutral , dried in an oven at 110°C to obtain 2.4 g of the final carbonized BC material; SiO prepared using this BC material 2 -BC-SO 3 The silica gel intercalation amount of the H catalyst is 17.1%, the wei...

Embodiment 3-6

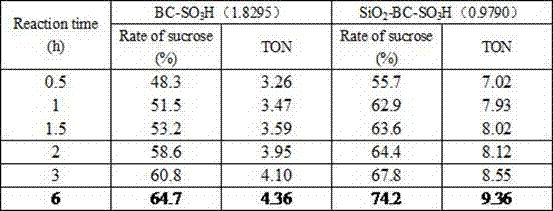

[0029] Embodiment 3-6, present embodiment 3-6 is used for illustrating the influence of the concentration of silica sol in the step (4) of embodiment 1, carries out according to the method for embodiment 1, and wherein silica sol consumption (calculated as silicon dioxide) is 20 wt%, and the pillaring temperature is 50°C. The impact results are shown in Table 1 below.

[0030] Preparation of 0.5 M silica sol concentration: adopt the operation steps of preparing 0.025 M silica sol in Example 1, add 10 mL of 1 M sodium silicate solution into 10 mL, 2 M of oxalic acid solution, and adjust the pH at 3.5~ Between 4.0; 0.05 M silica sol concentration preparation: Add 100 mL of 0.1 M sodium silicate solution to 100 mL, 0.12 M oxalic acid solution, and adjust the pH between 3.5 and 4.0; 0.033 M silica sol concentration preparation: Add 100 mL of 0.1 M sodium silicate solution to 200 mL of 0.12 M oxalic acid solution, and adjust the pH value between 3.5 and 4.0.

[0031] Table 1 Effe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com