Aqueous strippable resin, preparation method and applications,

A water-based, resin-based technology, applied in coatings and other directions, can solve the problems of many preparation steps, time-consuming and labor-intensive, complex process, etc., and achieve the effects of no environmental pollution, isolation of adverse effects, and low VOC content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

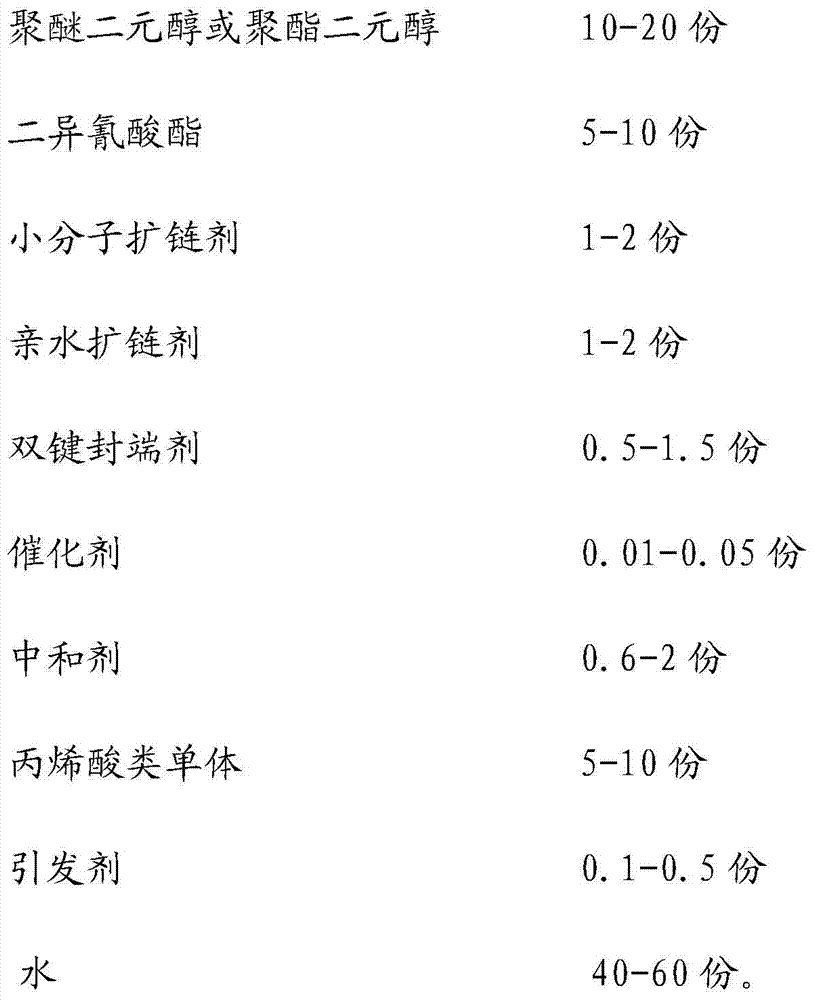

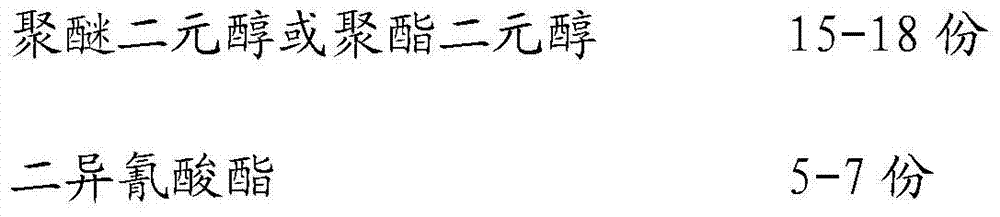

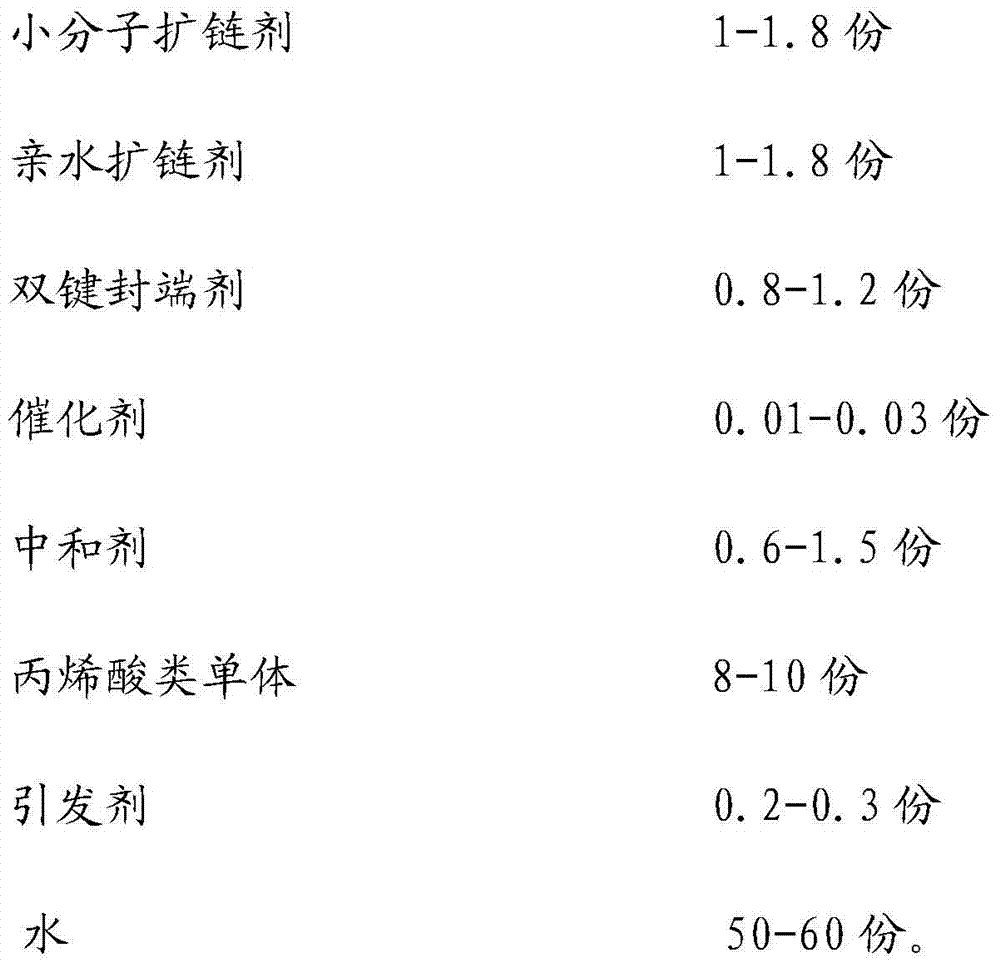

Method used

Image

Examples

Embodiment 1

[0030] A water-based peelable resin is prepared by the following preparation method:

[0031] (1) Put 10 parts by weight of polypropylene glycol with a molecular weight of 2000 into the reactor, raise the temperature to 100°C, vacuum dehydrate for 0.5h, then cool it down to 50°C and stop vacuuming, and add 5 parts by weight in turn under stirring Toluene diisocyanate, 1 part by weight of 1,4-butanediol, 1.2 parts by weight of dimethylolpropionic acid and 0.01 part by weight of stannous octoate, after the temperature is stabilized, slowly raise the temperature and control the reaction temperature at 70 ° C, react for 2 hours, Use the di-n-butylamine method to measure the NCO content in the prepolymer. After the NCO content is stabilized at 1.5-2.5%, cool down to 60°C, add 0.5 parts by weight of hydroxyethyl methacrylate, react for 1 hour, and cool down to 40°C. Add 1 part by weight of triethylamine, and after neutralizing for 15 minutes, add 1.5 parts by weight of methyl methac...

Embodiment 2

[0034] A water-based peelable resin is prepared by the following preparation method:

[0035](1) Put 10 parts by weight of polyethylene adipate with a molecular weight of 3000 into the reactor, heat up to about 100°C, vacuum dehydrate for 1 hour, then cool it down to 60°C, stop vacuuming, and stir Add 8 parts by weight of isophorone diisocyanate, 2 parts by weight of diethylene glycol, 1.4 parts by weight of dimethylol butyric acid and 0.02 parts by weight of dibutyltin dilaurate. After the temperature is stable, slowly heat up and control The reaction temperature is 80°C, react for 3 hours, measure the NCO content in the prepolymer by the di-n-butylamine method, after the NCO content is stabilized at 1.5-2.5%, cool down to 60°C, add 1.0 parts by weight of hydroxyethyl acrylate, React for 2 hours, lower the temperature to 50°C, add 1 part by weight of triethylamine, neutralize for 20 minutes, add 2 parts by weight of methyl methacrylate and 1 part by weight of n-butyl acrylate...

Embodiment 3

[0038] A water-based peelable resin is prepared by the following preparation method:

[0039] (1) Put 10 parts by weight of polytetrahydrofuran diol with a molecular weight of 2000 into the reactor, raise the temperature to about 120°C, vacuum dehydrate for 1 hour, then cool it down to 60°C and stop vacuuming, and add 10 parts by weight in turn under stirring 2 parts by weight of hexamethylene diisocyanate, 2 parts by weight of ethylenediamine, 2 parts by weight of dimethylolpropionic acid and 0.05 parts by weight of dibutyltin diacetate. After the temperature is stabilized, slowly raise the temperature and control the reaction temperature at 90°C for 2 hours , use the di-n-butylamine method to measure the NCO content in the prepolymer. After the NCO content is stabilized at 1.5-2.5%, cool down to 70°C, add 1.5 parts by weight of hydroxypropyl acrylate, react for 2 hours, and cool down to 50°C. Add 0.6 parts by weight of sodium hydroxide, after neutralizing for 30 minutes, add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com