Heavy metal contaminated soil repair conditioner and application thereof

A technology for polluted soil and heavy metals, applied in the restoration of polluted soil, soil conditioning materials, applications, etc., can solve the problems of reducing the mobility and bioavailability of heavy metals, improve soil fertilizer and water retention capacity, and the use method is simple. Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

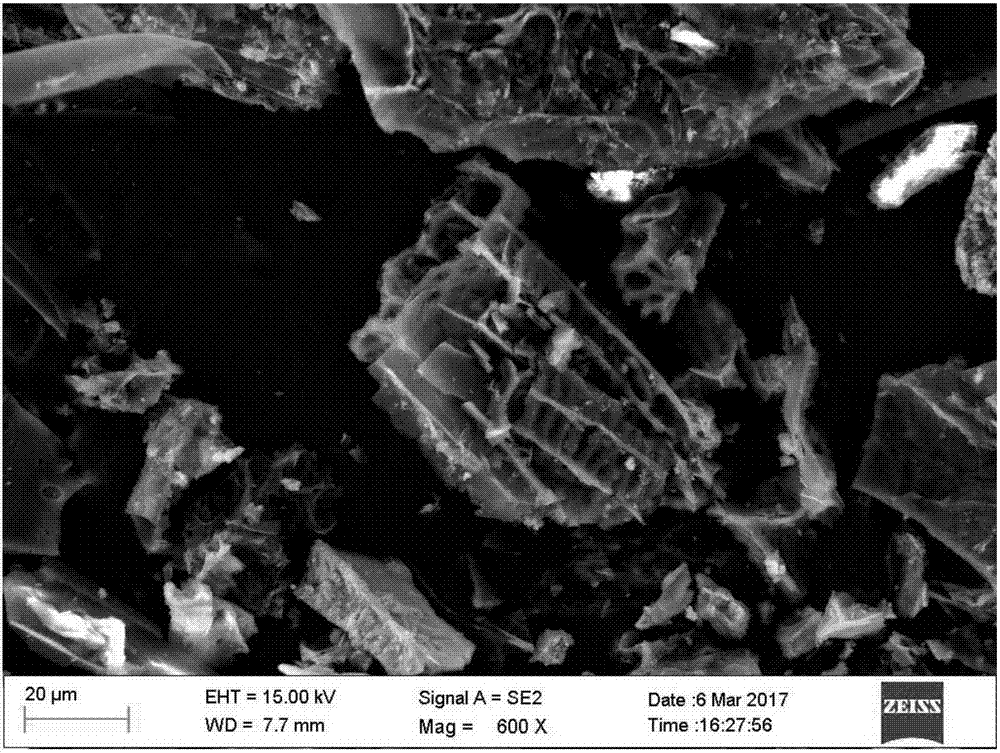

[0040] Select one or more of crop straw, cotton firewood, sawdust, rice husk or animal manure, and pyrolyze and carbonize them under anoxic conditions at 450-650°C to prepare biochar.

[0041] Weigh 10g of the biochar prepared by the above-mentioned method, add it to 100ml mass fraction of 10% Na 2 In the S solution, put a magnetic stirrer, adjust the rotation speed to 200rpm, stir at room temperature for 24h, filter with suction, dry at 105°C, put it in a tube furnace reactor, and heat up to 600°C at a rate of 10°C / min. Insulate for 60 minutes, cool to room temperature under nitrogen protection, wash with deionized water until neutral, and dry at 105°C to obtain sulfur-modified biochar.

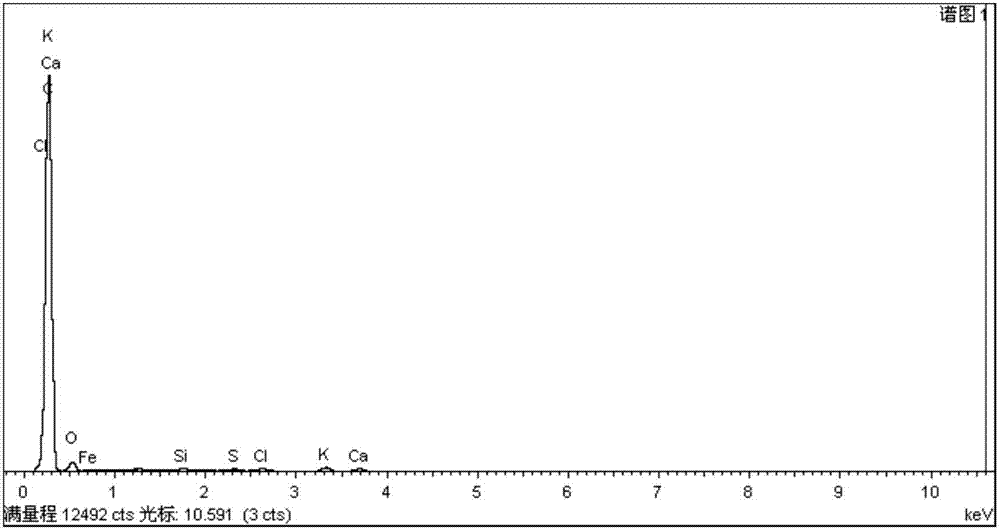

[0042] Weigh 4g of the sulfur-modified biochar prepared by the above method, 1g of attapulgite, 1g of zeolite powder, 0.5g of iron powder, and 0.5g of calcium oxide, mix and grind them, and pass through a 100-mesh sieve to obtain a heavy metal-contaminated soil remediation conditioner.

Embodiment 2

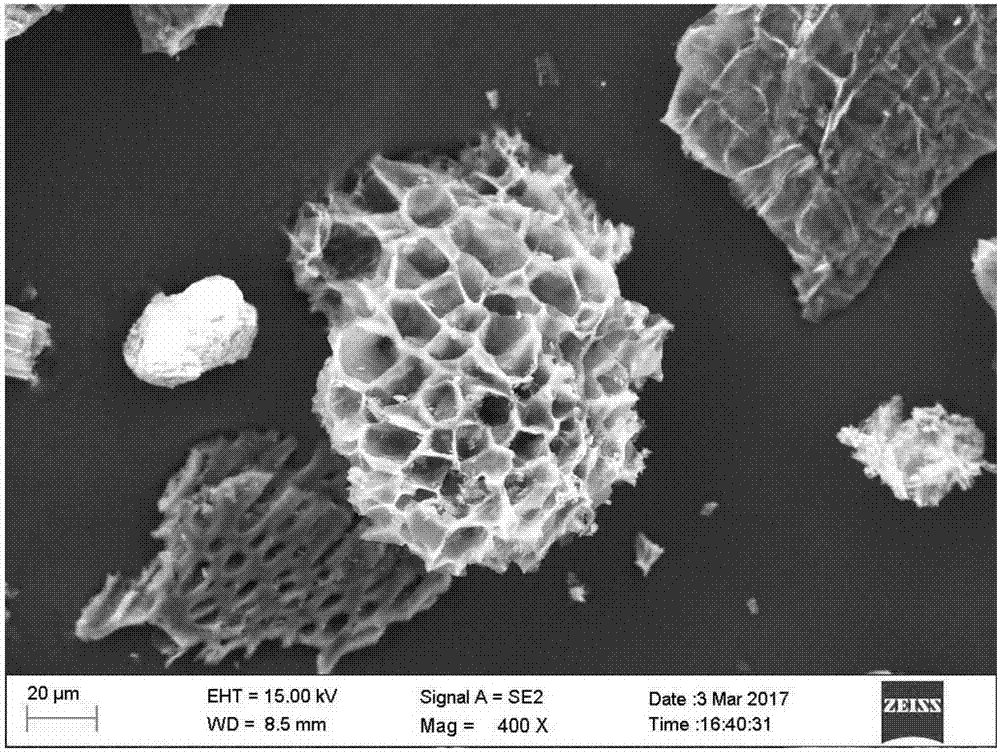

[0044] Select one or more of crop straw, cotton firewood, sawdust, rice husk or animal manure, and pyrolyze and carbonize them under anoxic conditions at 450-650°C to prepare biochar.

[0045] Weigh 10g of the biochar prepared by the above-mentioned method, add it to 100ml mass fraction of 10% Na 2 Put in a magnetic stirrer in the S solution, adjust the rotation speed to 200rpm, stir at room temperature for 24h, wash with water, filter with suction, dry in a constant temperature drying oven at 100°C, and age for 16h to obtain sulfur-modified biochar.

[0046] Weigh 5g of the sulfur-modified biochar prepared by the above method, 2g of attapulgite, 2g of zeolite powder, 0.5g of iron powder, and 0.5g of calcium oxide, mix and grind, and pass through a 100-mesh sieve to obtain a heavy metal-contaminated soil remediation conditioner.

Embodiment 3

[0048] Select one or more of crop straw, cotton firewood, sawdust, rice husk or animal manure, and pyrolyze and carbonize them under anoxic conditions at 450-650°C to prepare biochar.

[0049] Weigh 10 g of the biochar prepared by the above method and place it in a tube furnace under SO 2 Sulfur modification was carried out under atmospheric conditions, the modification temperature was 120° C., and the modification time was 5 hours to obtain sulfur-modified biochar.

[0050] Weigh 6g of sulfur-modified biochar prepared by the above method, 1.5g attapulgite, 1.5g zeolite powder, 0.5g iron powder, 0.5g calcium oxide, mix and grind, and pass through a 100-mesh sieve to obtain a heavy metal-contaminated soil remediation conditioner .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com