Crosslinking type aromatic polyimide material and preparation method thereof

A technology of aromatic polyimide and polyimide, which is applied in the field of cross-linked aromatic polyimide materials and its preparation, can solve problems such as material defects and affecting material performance, so as to reduce defects and improve Mechanical properties, the effect of simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Synthesis of polyamic acid: According to the molar ratio of 3,3'-dimethylbenzidinediamine: benzophenone dianhydride (BTDA)=1:1, 3,3'-dimethylbenzidine Phenylenediamine was added to the dried three-necked flask, and a metered amount of organic solvent N,N-dimethylacetamide (DMAc) was added. Stir under nitrogen to make it fully dissolved, then slowly add BTDA under mechanical stirring, so that the solid content of the solution is 15%. Then control the reaction temperature at 0-30° C. and react for 3 hours to obtain a viscous polyamic acid solution with an intrinsic viscosity of 1.9 dL / g.

[0046] (2) Preparation of polyimide fiber: put the polyamic acid prepared in the first step into the spinneret and defoam, adopt the method of wet hair spinning to prepare polyamic acid fiber, and the coagulation bath used is mass Concentration 6% DMAc aqueous solution. Then, the prepared polyamic acid fiber can be prepared into polyimide fiber by passing through a drying furnace ...

Embodiment 2

[0053] (1) Preparation of polyamic acid: According to the molar ratio of 3,3'-dimethylbenzidinediamine: benzophenone dianhydride (BTDA)=1:1, 3,3'-dimethylbenzidine Phenylenediamine was added to the dried three-necked flask, and a metered amount of organic solvent N,N-dimethylacetamide (DMAc) was added. Stir under nitrogen to make it fully dissolved, then slowly add BTDA under mechanical stirring, so that the solid content of the solution is 10%. Then control the reaction temperature at 0-30° C. and react for 5 hours to obtain a viscous polyamic acid solution with an intrinsic viscosity of 1.8 dL / g.

[0054] (2) Film making and imidization: the polyamic acid solution is evenly spread on the glass plate with a coating rod with a groove of 1 mm, and placed in the air to dry naturally to evaporate the solvent. Then put the dried film into a temperature-programmed muffle furnace for imidization. The imidization temperature is 350° C. for 2 hours.

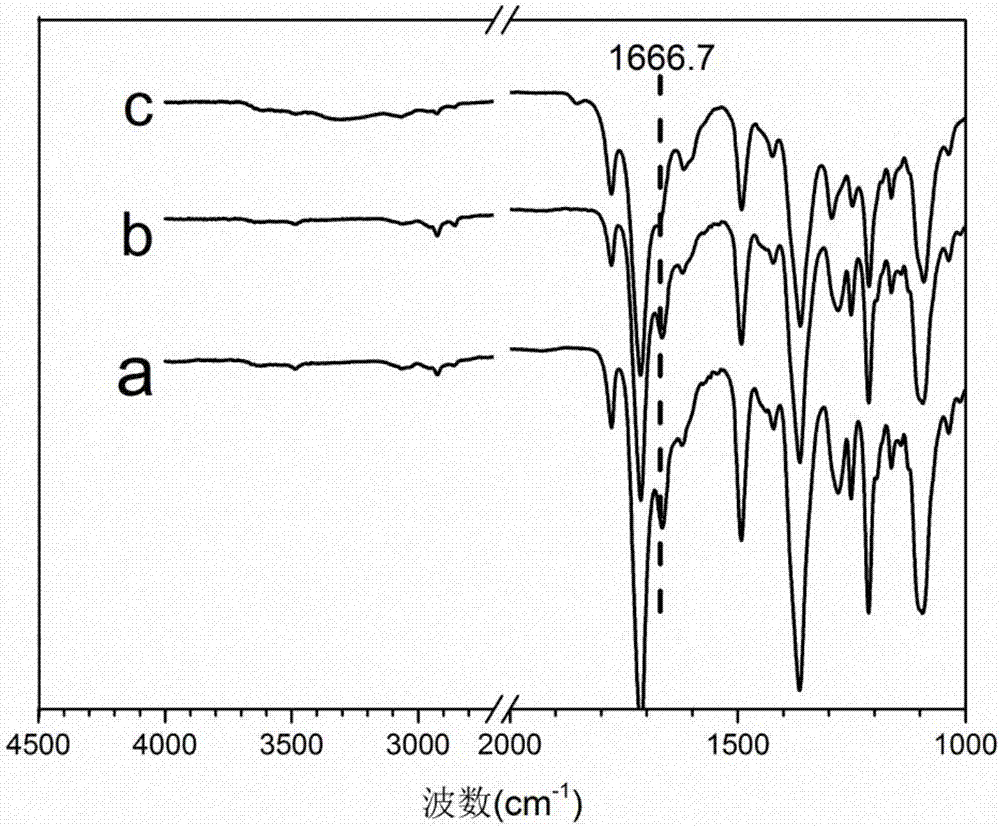

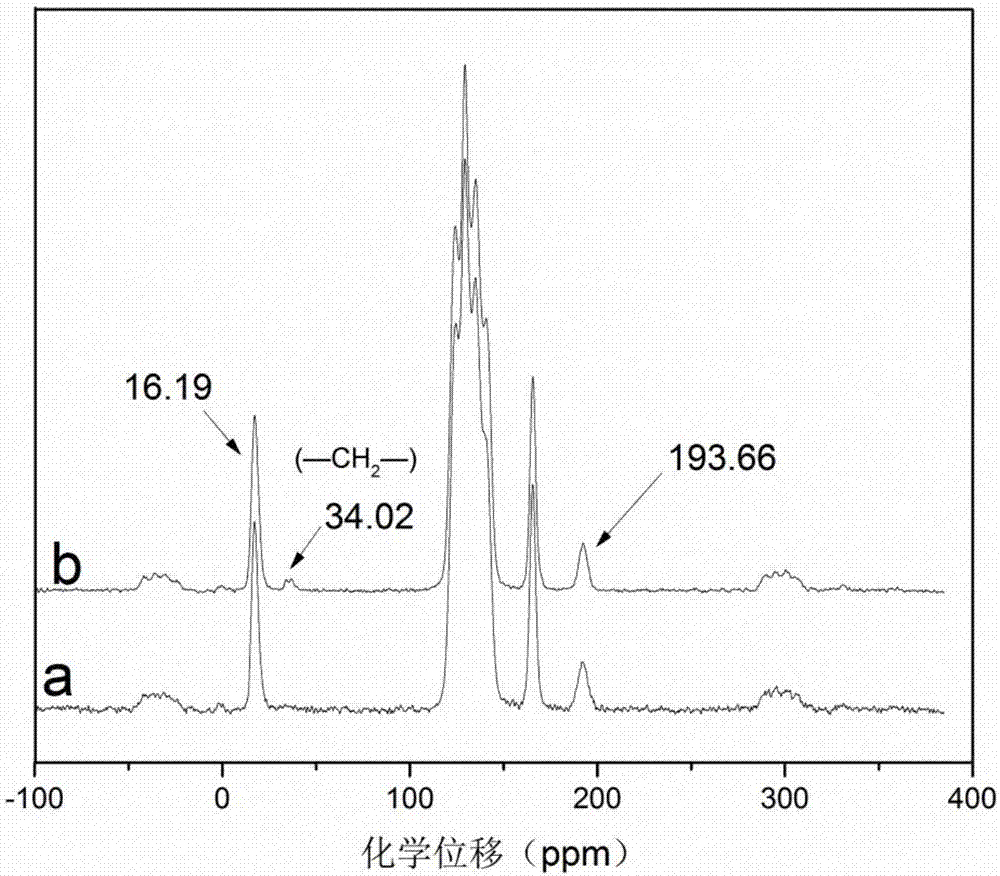

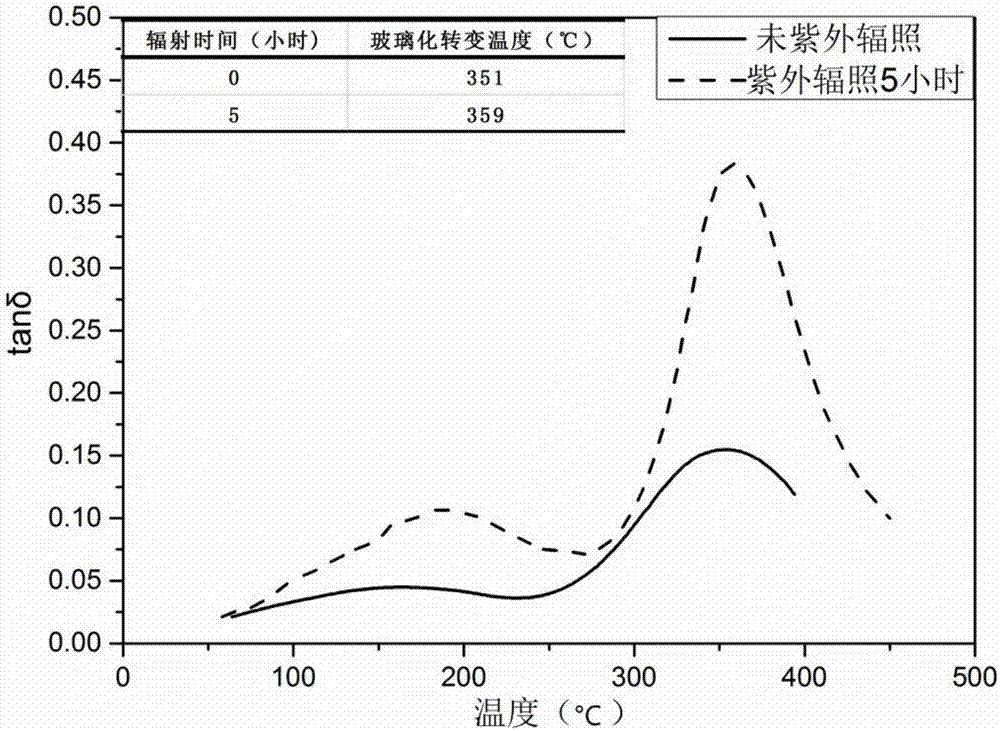

[0055] (3) Cross-linking proces...

Embodiment 3

[0060] (1) Preparation of polyamic acid: According to the molar ratio of 3,3'-dimethylbenzidine diamine: benzophenone dianhydride (BTDA): biphenyl dianhydride (BPDA) = 2:1:1, Add 3,3'-dimethylbenzidinediamine into the dried three-necked flask, and add a metered amount of organic solvent N,N-dimethylacetamide (DMAc). Stir under nitrogen to make it fully dissolved, then slowly add BTDA and BPDA that are uniformly mixed under mechanical stirring, so that the solid content of the solution is 8%. Control the reaction temperature at 0-30° C. and react for 3 hours to obtain a viscous ternary copolymerization polyamic acid solution with an intrinsic viscosity of 1.7 dL / g.

[0061] (2) Film making and imidization: the polyamic acid solution is evenly spread on the glass plate with a coating rod with a groove of 1 mm, and placed in the air to evaporate the solvent. Then put the dried film into a temperature-programmed muffle furnace for imidization. The imidization temperature is 350° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Initial modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com