Carbon membrane with triple functions of adsorption/electrocatalysis/membrane separation and its preparation method

A membrane separation and electrocatalysis technology, which is applied in semipermeable membrane separation, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the impact on health and life safety, high equipment investment, refractory degradation, bioaccumulation, etc. problems, to achieve the effect of saving equipment investment, simplifying advanced processing technology, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

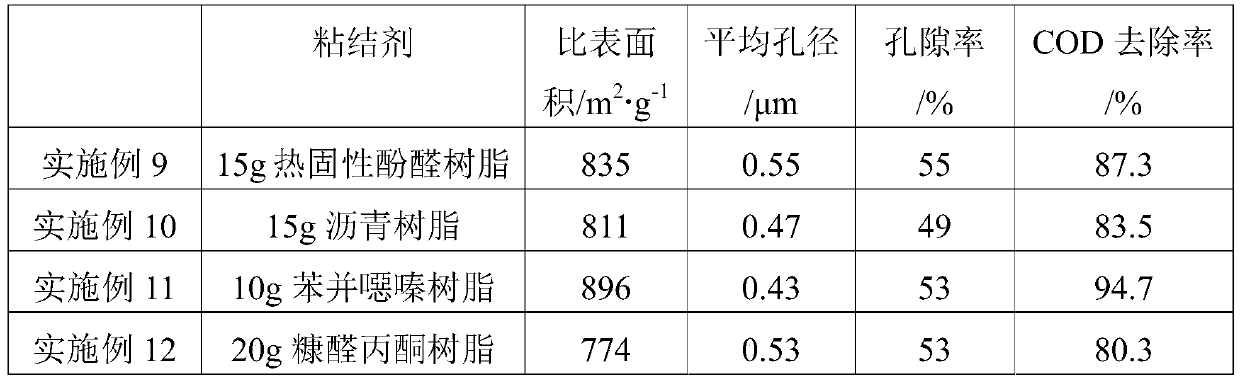

[0052] Get 90g activated carbon (median diameter is 15 μm, specific surface area is 1041m 2 / g), 3g graphite, 5g polyethylene chopped fibers, and 5g iron oxide powder are fully mixed, 15g carboxymethyl cellulose is dissolved in 75g hot water, and after cooling, it is added to the powder and mixed thoroughly, and then 15g thermosetting phenolic aldehyde is added Resin, after mixing and stirring, roll and grind the mud, seal and age for 48 hours, use an extruder to make a tubular original film, after completely drying, immerse the original film in 5wt% phenolic resin solution for 2 minutes, take it out at a uniform speed, dry it again, and put it under nitrogen protection Carbonization under low temperature (rise from room temperature at 3°C / min to 170°C, keep the temperature for 90 minutes, then rise to 800°C and keep the temperature for 30 minutes). The performance of the triple-functional carbon membrane is obtained, as shown in Table 1, wherein the treatment effect is the re...

Embodiment 2~4

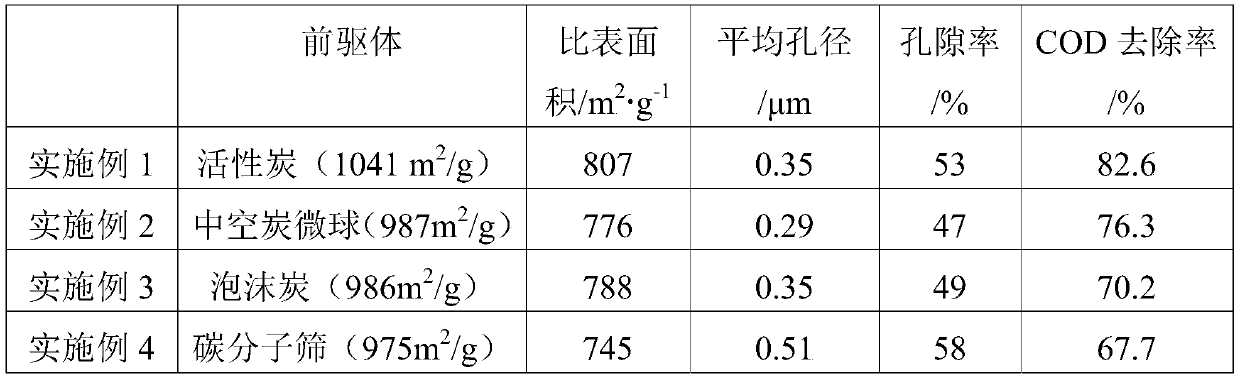

[0054] According to the steps of Example 1, but the precursor was prepared according to the parameters in Table 1, the properties of the obtained triple-functional carbon membrane are shown in Table 1.

[0055] Table 1

[0056]

Embodiment 5

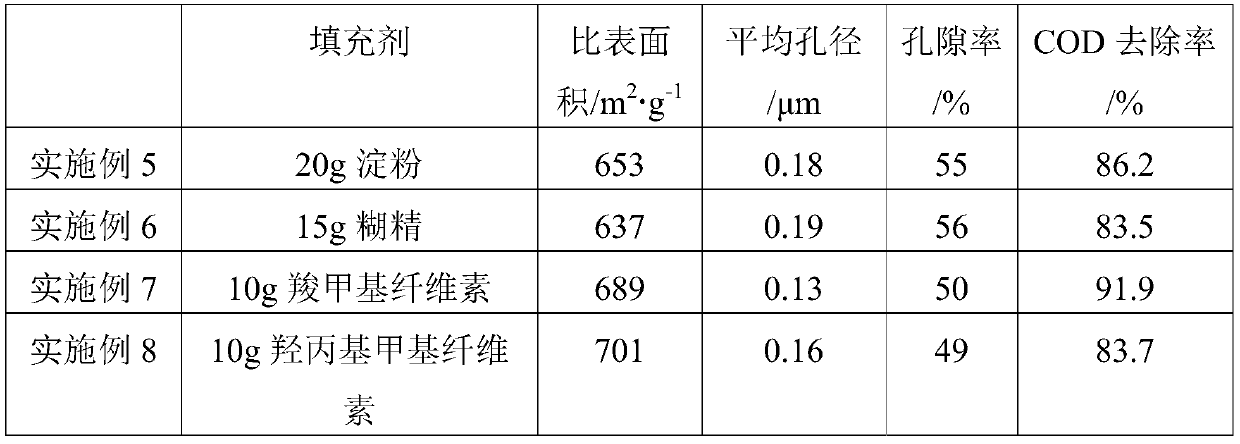

[0058] Get 90g hollow carbon microspheres (median diameter is 18 μm, specific surface area is 805m 2 / g), 5g of carbon black, 3g of polyester chopped fiber and 3g of titanium dioxide powder are fully mixed, 20g of starch is dissolved in 80g of hot water, after cooling, they are added to the powder and fully mixed, then 20g of benzoxazine resin is added, and mixed After stirring, grind the mud with a roller, seal and age for 48 hours, use an extruder to make a tubular original film, dry it and carbonize it under the protection of nitrogen. , keep the temperature for 30 minutes, take it out after natural cooling, and obtain the carbon film substrate. The prepared carbon membrane substrate was immersed in a 10wt% polyimide solution for 5 minutes, then taken out at a constant speed, dried and carbonized under the protection of nitrogen (5°C / min to 550°C for 30min). The performance of the triple function carbon membrane is obtained, as shown in Table 2, wherein the treatment effec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com