Method for improving cut stem sensory quality by proline solid phase Maillard reaction

A technology of Maillard reaction and proline, which is applied in the field of tobacco processing, can solve the problems of high smoke irritation, insufficient reaction, and insufficient aroma, so as to reduce smoke irritation and miscellaneous gas, increase usability and use Quantity and process conditions are simple and mild

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

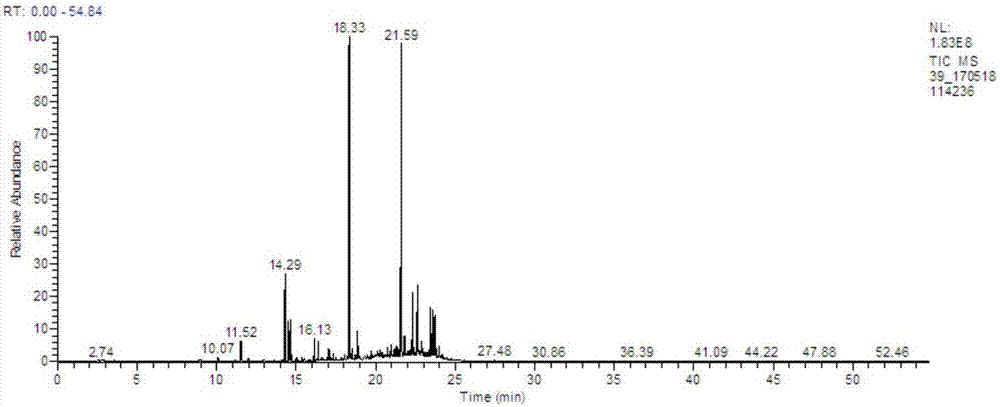

Embodiment 1

[0028] A method for improving the sensory quality of shredded stems by proline solid-phase Maillard reaction, comprising the following steps:

[0029] (1) Raw material preparation; Proline and glyceraldehyde, ribose are as Maillard reaction substrate, account for 0.04% of cut stem quality, the mol ratio of proline and glyceraldehyde, ribose 2.5:0.5:0.5, reaction catalyst is Ammonia and diammonium hydrogen phosphate, the mass ratio is 1:1, the catalyst accounts for 0.4% of the Maillard reaction substrate mass, and the mass ratio of water to the Maillard reaction substrate is 1.5:1;

[0030] (2) Proline solid-phase Maillard reaction in the shredded stem feeding process: add water at 65°C, proline, and glyceraldehyde in sequence according to the ratio of the above step 1), stir well until they are completely dissolved, and then add the reaction Catalyst ammonia water and diammonium hydrogen phosphate, mixed evenly, evenly sprayed on the cut stems, the moisture content of the cut ...

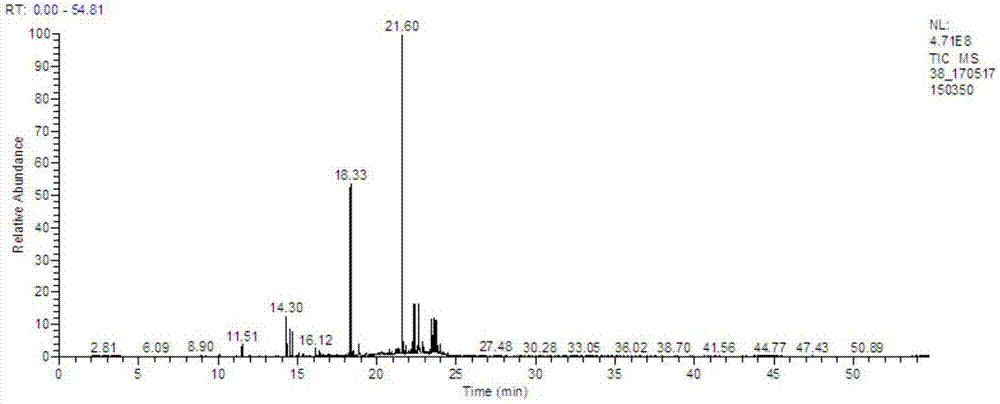

Embodiment 2

[0035] A method for improving the sensory quality of shredded stems by proline solid-phase Maillard reaction, comprising the following steps:

[0036] (1) Raw material preparation; Proline and fermented raisin extract are used as Maillard reaction substrate, account for 0.08% of cut stem quality, be 3:1 by the mass ratio of proline and fermented raisin extract, reaction catalyst is Ammonium glycyrrhizinate and vitamin C have a mass ratio of 1:1, accounting for 0.9% of the Maillard reaction substrate mass, and the mass ratio of water to the Maillard reaction substrate is 2:1;

[0037] (2) Proline solid-phase Maillard reaction in the shredded stem feeding process: add water at 70°C, proline, and fermented raisin extract in a certain proportion in sequence, stir well until completely dissolved, and then add the reaction catalyst licorice ammonium nitrate and vitamin C, mixed evenly, evenly sprayed on the shredded stems, so that the moisture content of the shredded stems reached 2...

Embodiment 3

[0043] A method for improving the sensory quality of shredded stems by proline solid-phase Maillard reaction, comprising the following steps:

[0044] (1) Raw material preparation; proline, caramel, deoxyribose, and fermented raisin extract are used as Maillard reaction substrates, accounting for 0.15% of the cut stem mass, extracted by proline, caramel, deoxyribose, and fermented raisins The mass ratio of substance is 3:1, and caramel, deoxyribose and fermented raisin extract are equal mass ratio, and reaction catalyst is ammonium alginate, ammoniacal liquor, and mass ratio is 1:1, and catalyzer accounts for Maillard reaction substrate quality 0.3%, the mass ratio of water to Maillard reaction substrate is 4:1;

[0045] (2) Proline solid-phase Maillard reaction in the shredded stem feeding process: add water at 75°C, proline, and sugar source in a certain proportion in sequence, stir thoroughly until completely dissolved, then add the reaction catalyst, and mix well , evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com