Heat-resistant and anti-corrosion 3D printing material for electronic engineering and preparation method thereof

A 3D printing and electronic engineering technology, applied in the field of 3D printing materials, it can solve the problems of macromolecular fracture, easy loss of electrons, material aging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

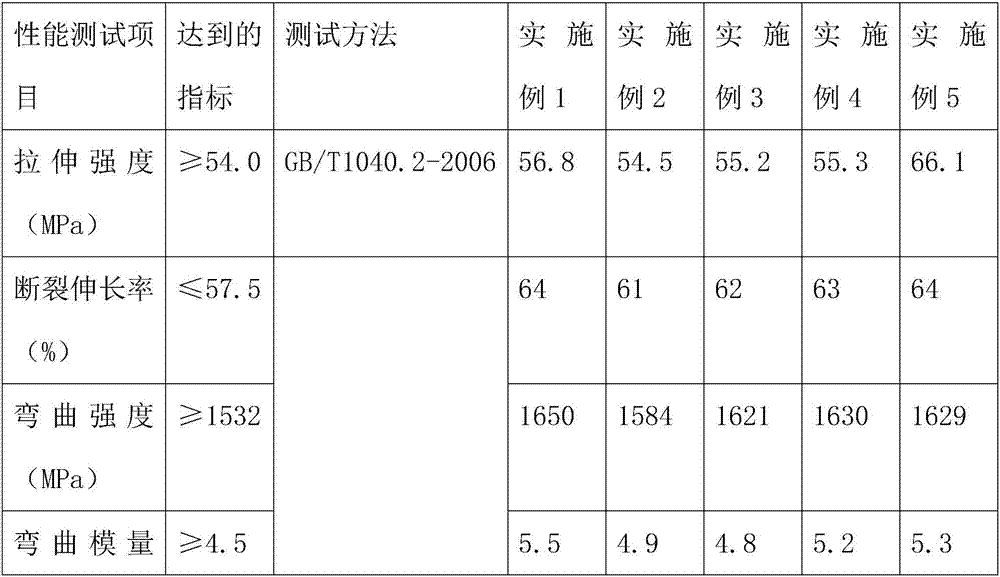

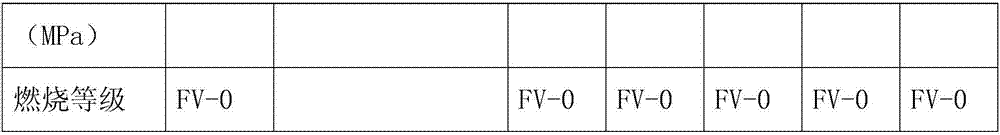

Examples

Embodiment 1

[0016] A heat-resistant and anti-corrosion 3D printing material for electronic engineering proposed by the present invention, its raw materials include by weight: 100 parts of modified polyphenylene sulfide, 25 parts of EPDM rubber, 10 parts of styrene-butadiene rubber, and 6 parts of epoxy resin 4.5 parts of polyurethane acrylate, 3.5 parts of melamine hydrobromide, 2.5 parts of EPDM rubber, 5.5 parts of polyphosphate amine, 4.5 parts of aluminum hydroxide, 6 parts of talcum powder, 3 parts of mica iron oxide, 3.5 parts of zinc oxide , 4 parts of magnesium oxide, 4.5 parts of asbestos fiber, 4 parts of glass fiber, 4.5 parts of nano-titanium dioxide, 3.5 parts of ethyl orthosilicate, 3 parts of silane coupling agent KH-560, 4.5 parts of trioctyl trimellitate, hard 4 parts of sodium fatty acid, 6 parts of dioctyl phthalate, 3.5 parts of dicumyl peroxide, 2.5 parts of m-xylylenediamine, 4.5 parts of benzotriazole, 4 parts of ammonium polyphosphate, dimethyl phosphate 6 parts of...

Embodiment 2

[0021] A heat-resistant and anti-corrosion 3D printing material for electronic engineering proposed by the present invention, its raw materials include: 80 parts of modified polyphenylene sulfide, 35 parts of EPDM rubber, 5 parts of styrene-butadiene rubber, and 9 parts of epoxy resin in parts by weight. 3 parts of polyurethane acrylate, 6 parts of melamine hydrobromide, 1 part of EPDM rubber, 8 parts of polyphosphate amine, 3 parts of aluminum hydroxide, 9 parts of talcum powder, 1 part of mica iron oxide, 5 parts of zinc oxide , 3 parts of magnesium oxide, 6 parts of asbestos fiber, 3 parts of glass fiber, 6 parts of nano-titanium dioxide, 2 parts of ethyl orthosilicate, 5 parts of silane coupling agent KH-560, 3 parts of trioctyl trimellitate, hard 5 parts of sodium fatty acid, 3 parts of dioctyl phthalate, 6 parts of dicumyl peroxide, 1 part of m-xylylenediamine, 6 parts of benzotriazole, 3 parts of ammonium polyphosphate, dimethyl phosphate 8 parts of methyl ester, 3 part...

Embodiment 3

[0026]A heat-resistant and anti-corrosion 3D printing material for electronic engineering proposed by the present invention, its raw materials include by weight: 120 parts of modified polyphenylene sulfide, 15 parts of EPDM rubber, 15 parts of styrene-butadiene rubber, and 3 parts of epoxy resin 6 parts of polyurethane acrylate, 1 part of melamine hydrobromide, 4 parts of EPDM rubber, 3 parts of polyphosphate amine, 6 parts of aluminum hydroxide, 3 parts of talcum powder, 5 parts of mica iron oxide, 2 parts of zinc oxide , 5 parts of magnesium oxide, 3 parts of asbestos fiber, 5 parts of glass fiber, 3 parts of nano-titanium dioxide, 5 parts of ethyl orthosilicate, 1 part of silane coupling agent KH-560, 6 parts of trioctyl trimellitate, hard 3 parts of sodium fatty acid, 9 parts of dioctyl phthalate, 1 part of dicumyl peroxide, 4 parts of m-xylylenediamine, 3 parts of benzotriazole, 5 parts of ammonium polyphosphate, dimethyl phosphate 4 parts of methyl ester, 5 parts of liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com