Preparation method of polyamine nanoparticle self-assembled nanofiltration membrane

A technology of nano-particles and polyamines, which is applied in the field of preparation of self-assembled nanofiltration membranes of polyamine nanoparticles, can solve the problems of fast interfacial polymerization reaction rate and difficult control, difficult separation performance of polyamide composite membranes, etc., and achieve good industrial application Foreground, easy regulation, effect of good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

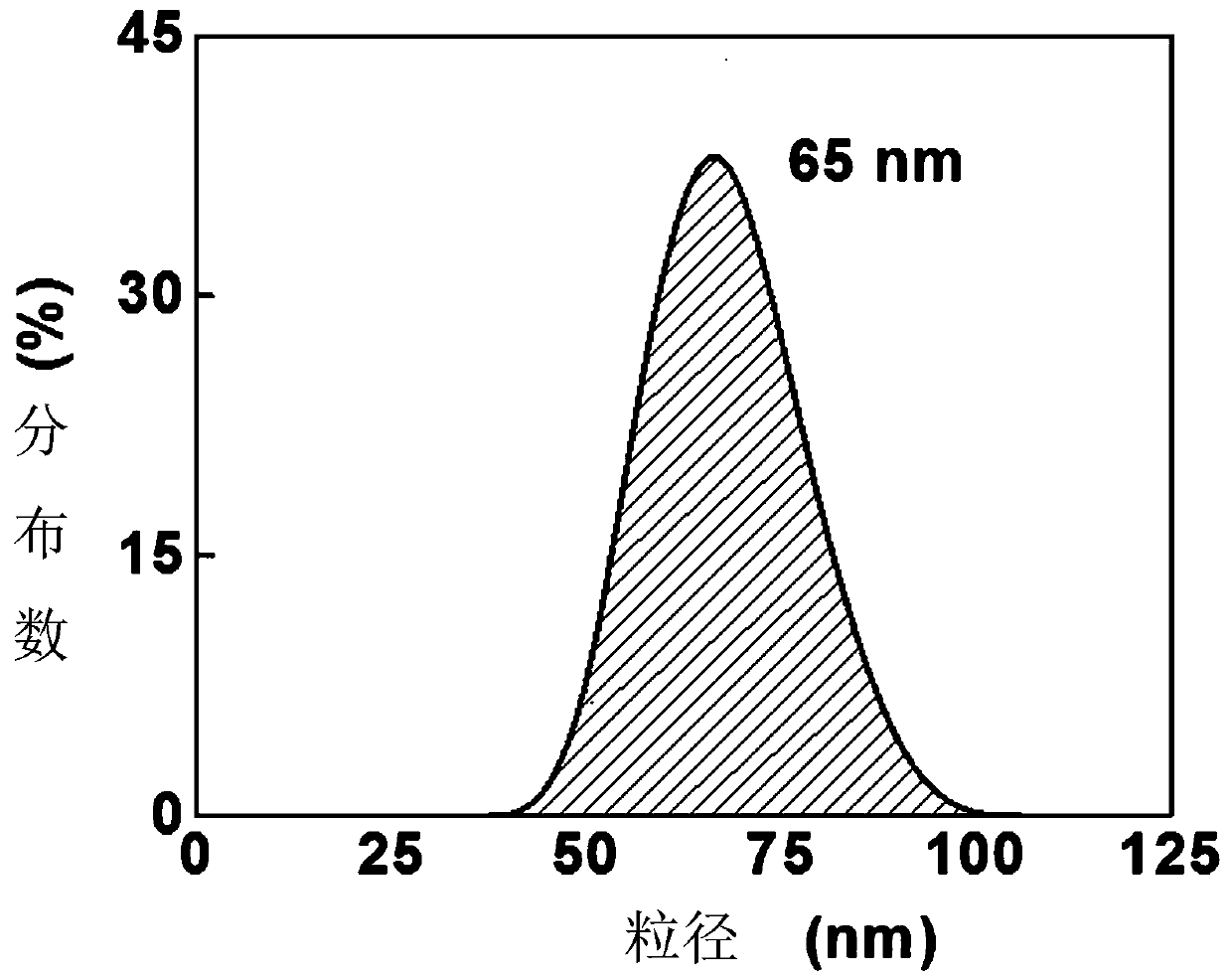

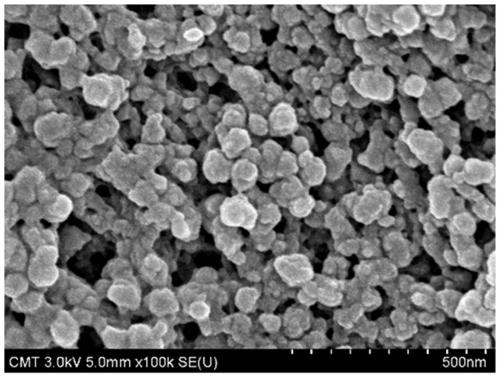

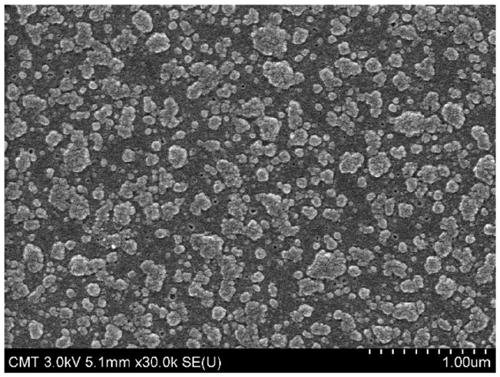

[0020] Take 0.1g piperazine and 0.02g dopamine and dissolve in 100g mass percent concentration of 0.01wt% sodium hydroxide aqueous solution, feed oxygen, polymerize at 15°C for 6 hours, centrifuge at 12000 rpm for 20 minutes, After washing with deionized water and vacuum-drying at 60°C for 4 hours, polyamine nanoparticles were obtained; then, 0.1 g of the above-mentioned nanoparticles were added to 100 g of aqueous sodium hydroxide solution with a mass percent concentration of 0.001 wt % to form a nanoparticle base aqueous dispersion; immerse the polysulfone ultrafiltration membrane in the above aqueous dispersion for 1 minute, take out and remove the excess aqueous dispersion on the surface of the membrane to form a self-assembled membrane of polyamine nanoparticles; In 0.1wt% trimesoyl chloride n-hexane solution, interfacial crosslinking reaction was carried out for 0.5 minutes, solidified at 40°C for 30 minutes, and washed with deionized water to obtain polyamine nanocomposi...

Embodiment 2

[0023] Dissolve 2g of piperazine and 0.5g of dopamine in 100g of 0.1wt% sodium hydroxide aqueous solution, feed oxygen, polymerize at 25°C for 0.5 hour, centrifuge at 5000 rpm for 60 minutes, and After washing with deionized water and vacuum drying at 40°C for 12 hours, polyamine nanoparticles were obtained; then the above 2g of nanoparticles were added to 100g of sodium hydroxide aqueous solution with a mass percentage concentration of 0.01wt% to form nanoparticles alkaline water Dispersion liquid: soak the porous polysulfone ultrafiltration membrane in the above-mentioned aqueous phase dispersion liquid for 10 minutes, take out and remove the excess aqueous phase dispersion liquid on the surface of the membrane to form a self-assembled membrane of polyamine nanoparticles; In wt% trimesoyl chloride n-hexane solution, interfacial crosslinking reaction was carried out for 5 minutes, solidified at 65°C for 10 minutes, and washed with deionized water to obtain polyamine nanocompos...

Embodiment 3

[0026]Dissolve 1 g of piperazine and 0.1 g of dopamine in 100 g of 0.05 wt% sodium hydroxide aqueous solution, feed oxygen, polymerize at 25°C for 3 hours, centrifuge at 10,000 rpm for 30 minutes, and After washing with deionized water and vacuum drying at 50°C for 8 hours, polyamine nanoparticles were obtained; then the above 1g of nanoparticles was added to 100g of sodium hydroxide aqueous solution with a mass percentage concentration of 0.01wt% to form nanoparticles alkaline water Dispersion solution: soak the porous polysulfone ultrafiltration membrane in the above aqueous dispersion solution for 3 minutes, take out and remove the excess aqueous dispersion solution on the surface of the membrane to form a self-assembled membrane of polyamine nanoparticles; In the wt% trimesoyl chloride n-hexane solution, the interfacial crosslinking reaction was carried out for 2 minutes, cured at 50°C for 15 minutes, and washed with deionized water to obtain the polyamine nanocomposite nan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com