Ethylene propylene diene monomer, and preparation method thereof

A technology of EPDM rubber and raw rubber, which is applied in the field of rubber and can solve problems such as poor mechanical properties, slow vulcanization speed, and large compression deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

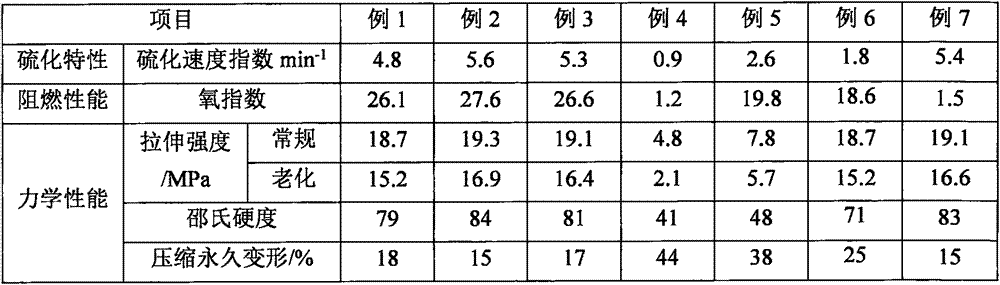

Examples

preparation example Construction

[0022] Correspondingly, the present invention also provides a preparation method of EPDM rubber, comprising the following steps: adding 100-150 parts by weight of raw EPDM rubber to a Haake rheometer, and then adding 0.5-1 parts by weight parts by weight of sulfur, 1-6 parts by weight of zinc oxide, 0.5-2 parts by weight of accelerators, 5-20 parts by weight of flame retardants, 0.5-3 parts by weight of anti-aging agents and 5-20 parts by weight of functional fillers, the temperature of the rubber compound reaches 105- Discharge the rubber material at 120°C, the functional filler is polyionic liquid coated nano-calcium carbonate particles; mix the rubber material evenly on an open mill, pack it into a triangular bag, thin it, and then release it to obtain a mixed rubber; Put the mixed rubber at room temperature, and vulcanize to obtain EPDM rubber, the vulcanization pressure is 10-25MPa, the vulcanization temperature is 160-180°C, and the vulcanization time is 100-150s.

[002...

Embodiment 1

[0036] Accelerator of the present invention is ionic liquid trimethyltetradecyl quaternary phosphine cation 2-mercaptobenzothiazole anion salt, and concrete preparation method is as follows:

[0037] Mix 0.1mol ionic liquid trimethyltetradecyl quaternary phosphine salt and 50mL methanol to prepare a solution, add 0.1mol 2-mercaptobenzothiazole and 0.1mol sodium hydroxide, stir magnetically at 25°C for 24h, and stop the reaction The unreacted impurity solids were removed by filtration, washed with acetone, and the product was dried in a drying oven at 50° C. for 8 hours to obtain an accelerator, which was set aside.

[0038] The ionic liquid monomer is vinylimidazolium cation n-butyl xanthate anion salt, and the specific preparation method is as follows:

[0039] Mix 0.1 mol of ionic liquid vinylimidazolium bromide and 30 ml of methanol to prepare a solution, add 0.1 mol of n-butyl xanthate, stir magnetically at 0°C for 18 hours, stop the reaction and filter to remove unreacted...

Embodiment 2

[0048] The preparation method of accelerator and functional filler is the same as embodiment 1, the preparation method of high-performance EPDM rubber, and its steps are as follows:

[0049] Set the initial temperature of the Haake rheometer to 50°C, the rotational speed to 40r / min, and the debinding temperature to 90°C to avoid early scorching of the rubber. Add 150 parts by weight of raw EPDM rubber to the Haake rheometer, and after the torque is stable, add 0.5 parts by weight of sulfur, 2 parts by weight of zinc oxide, 5 parts by weight of functional filler, and 10 parts by weight of flame retardant , 0.75 parts by weight of an accelerator and 3 parts by weight of an anti-aging agent, and the rubber material is discharged when the temperature of the rubber material reaches 120°C. The rubber material mixed in the Haake rheometer is further mixed evenly on the open mill, and the triangle bag is made three times on the left and right, and after five times of thinning, the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com