Zirconium-doped modified nickel cobalt manganese lithium oxide/lithium titanate composite cathode material

A technology of nickel-cobalt-manganese-lithium oxide and composite cathode materials, which is applied in electrode manufacturing, battery electrodes, electrode heat treatment, etc., can solve the problems of poor repeatability of nickel-cobalt-manganese-lithium oxide, and reduce production processes, improve rate performance and cycle performance. , the effect of improving the first Coulomb efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

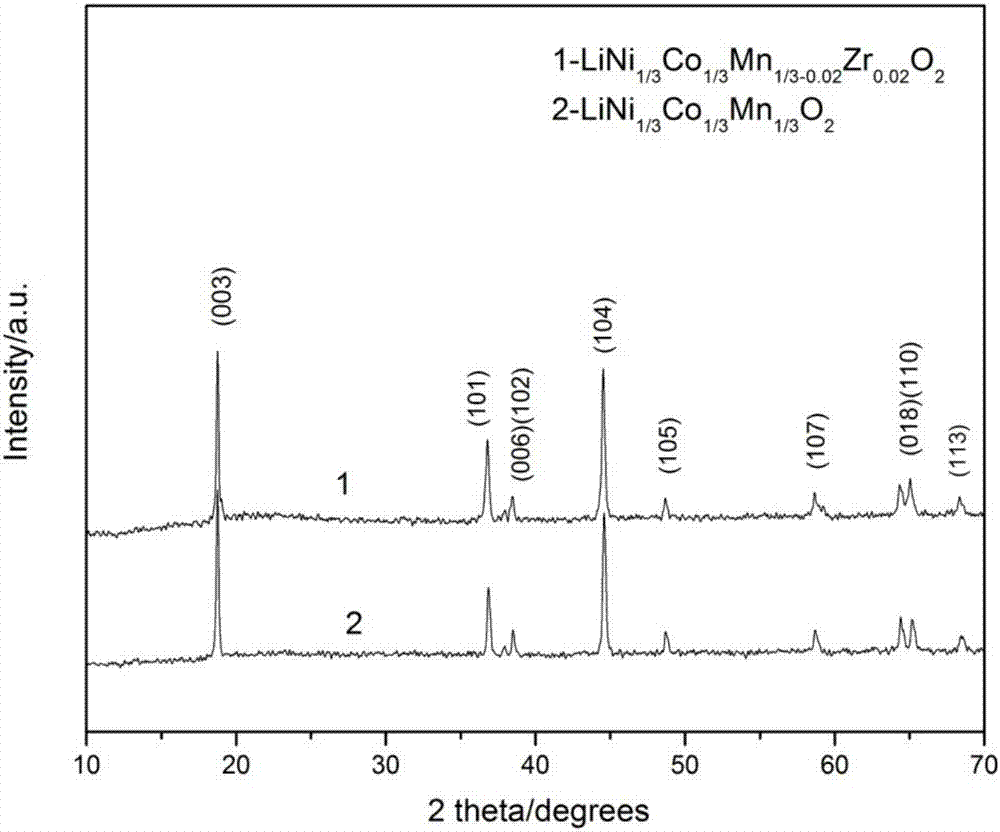

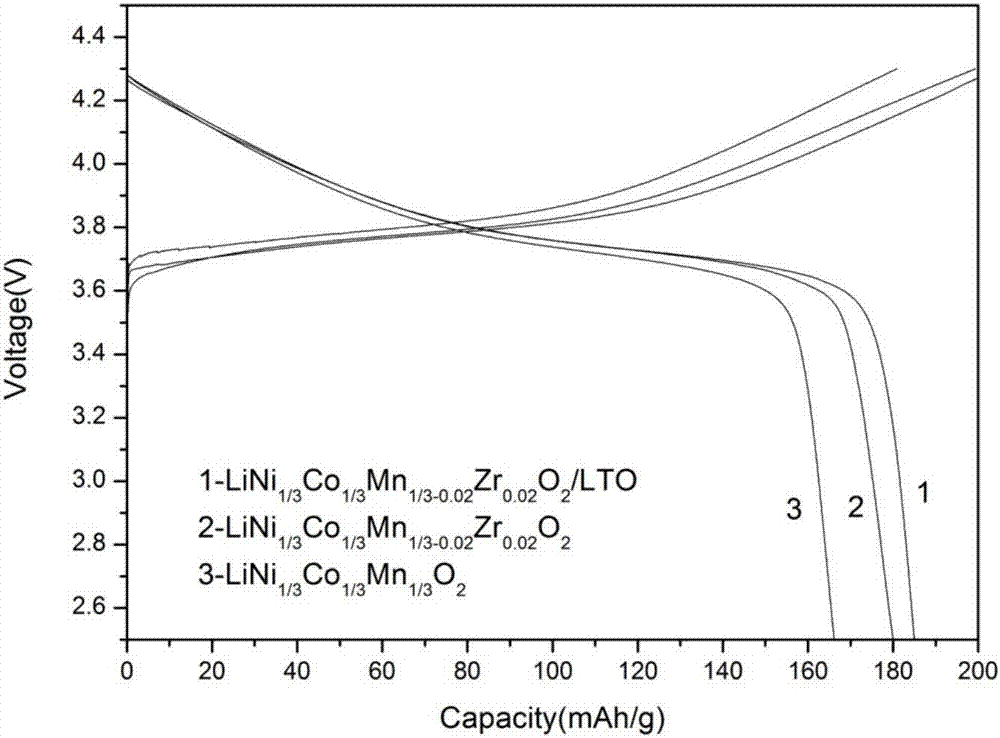

Embodiment 1

[0042] In this embodiment, the lithium-ion battery nickel-cobalt-manganese-lithium positive electrode material is prepared according to the following steps:

[0043] Take by weighing 0.536g lithium acetate, 0.409g manganese acetate, 0.276g cobalt acetate, be dissolved in the mixed solution of 10ml water and 50ml ethanol, be recorded as A solution, in order to make up for the loss of lithium source in the calcining process, lithium acetate is excessive 5%; Weigh 0.415g of nickel acetate and 0.138g of cobalt acetate and dissolve them in a mixed solution of 10ml of water and 50ml of ethanol, and record it as solution B; weigh 1.1649g of dihydrate oxalic acid, dissolve it in a mixed solution of 10ml of water and 50ml of ethanol, and record it as C solution. Add solution A to solution C dropwise to make it precipitate. After 10 minutes, pour solution B into solution C and react at room temperature for 5 hours. Then it was dried in an oven at 80°C for 12 hours, and ground to obtain...

Embodiment 2

[0046] In this example, the nickel oxide cobalt manganese lithium positive electrode material modified by zirconium doping for lithium ion battery is prepared according to the following steps:

[0047] a, take by weighing 0.536g lithium acetate, 0.409g manganese acetate, 0.276g cobalt acetate, dissolve in the mixed solution of 10ml water and 50ml ethanol, record as A solution, in order to make up for the loss of lithium source in the calcining process, lithium acetate is excessive 5 %; Weigh 0.415g of nickel acetate, 0.138g of cobalt acetate and dissolve in a mixed solution of 10ml of water and 50ml of ethanol, which is referred to as solution B; weigh 1.1649g of dihydrate oxalic acid, dissolve in a mixed solution of 10ml of water and 50ml of ethanol, Recorded as C solution. Add solution A to solution C dropwise to make it precipitate. After 10 minutes, pour solution B into solution C and react at room temperature for 5 hours. Then it was dried in an oven at 80°C for 12 hours...

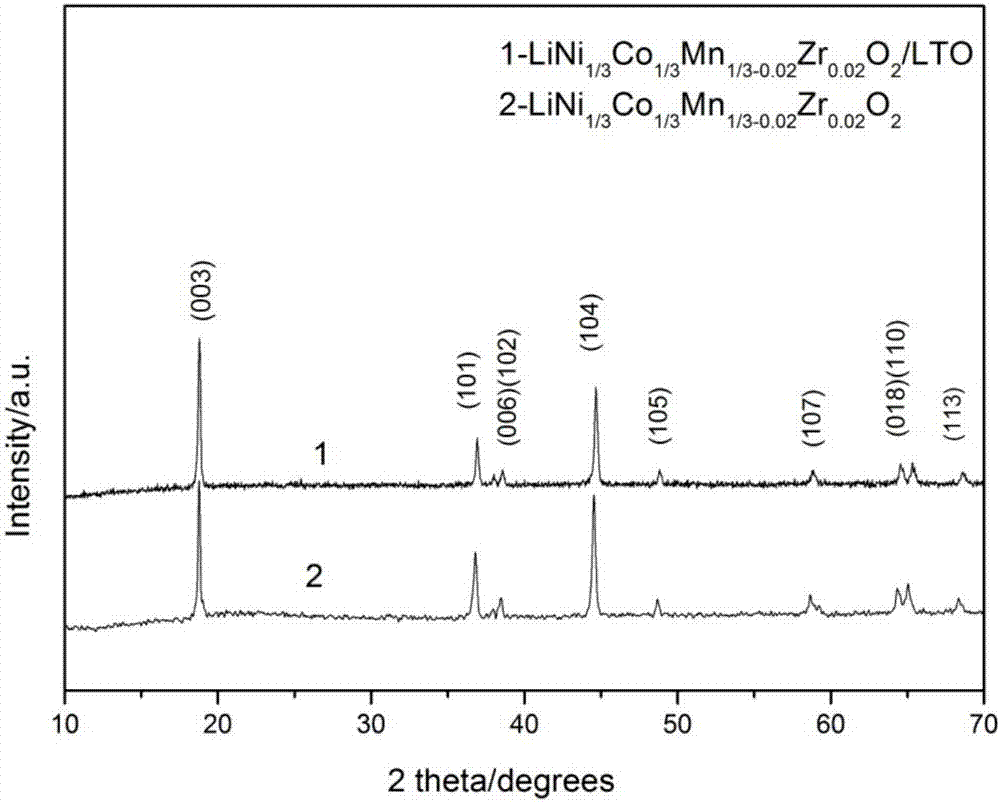

Embodiment 3

[0052] In this example, the nickel oxide cobalt manganese lithium positive electrode material modified by zirconium doping for lithium ion battery is prepared according to the following steps:

[0053]Weigh 0.536g lithium acetate, 0.381g manganese acetate, 0.276g cobalt acetate, 0.091g zirconium nitrate, dissolve in the mixed solution of 10ml water and 50ml ethanol, and record it as solution A. In order to make up for the loss of lithium source in the calcining process, acetic acid Lithium excess 5%; Weigh 0.415g of nickel acetate and 0.138g of cobalt acetate and dissolve in a mixed solution of 10ml of water and 50ml of ethanol, and record it as solution B; Weigh out 1.1649g of dihydrate oxalic acid, dissolve in a mixture of 10ml of water and 50ml of ethanol solution, denoted as C solution. Add solution A to solution C dropwise to make it precipitate. After 10 minutes, pour solution B into solution C and react at room temperature for 5 hours. Then it was dried in an oven at 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com