Method for preparing lactic acid by using Cu-Pd (copper-palladium) alloy catalyst to catalyze high-concentration glycerin

An alloy catalyst, high-concentration technology, used in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, preparation of organic compounds, etc. And glycerol conversion rate is low, undisclosed catalyst recycling performance and other problems, to achieve good industrialization prospects, high recycling performance, low investment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

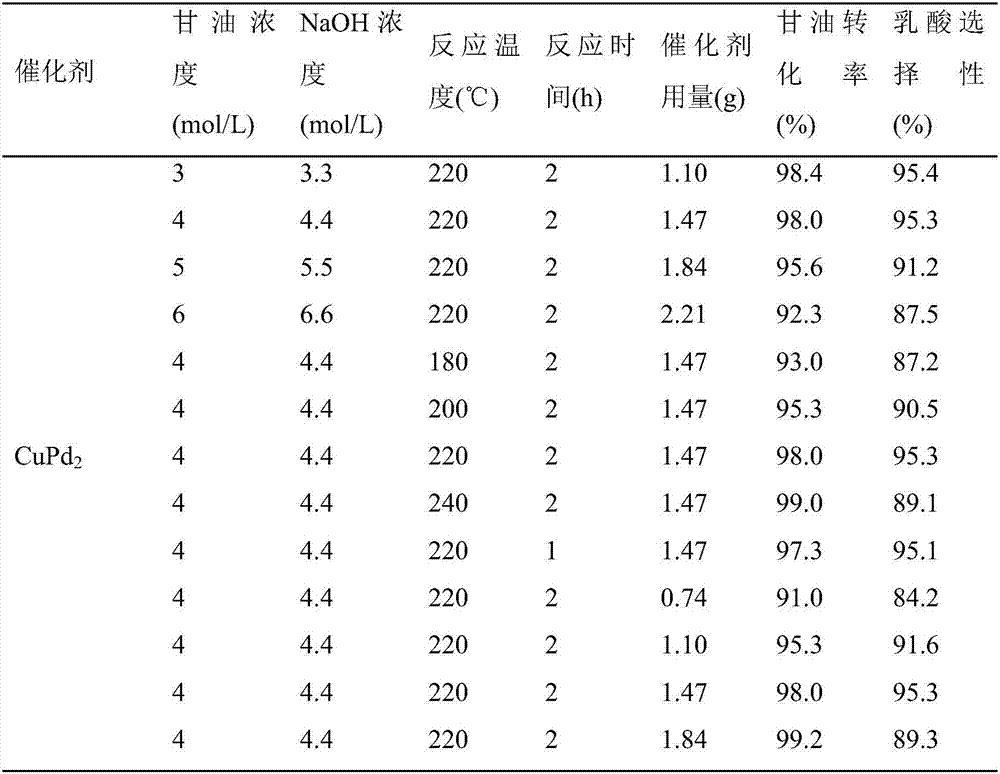

Embodiment 1

[0026] Copper-palladium alloy catalyst (CuPd 2 ) preparation: weigh 1.8268g Cu(NO 3 ) 2 ·3H 2 O and 0.04028g Pd(NO 3 ) 2 2H 2 0, to ensure that the total mass of the catalyst copper-palladium alloy is 0.5g. First the Cu(NO 3 ) 2 ·3H 2 O was added to 40 mL of 12.5% polyethylene glycol 20000 absolute ethanol solution and ultrasonically treated for 30 min to completely dissolve it, then pour the solution into a round bottom flask equipped with a stirrer, and preheat it in a water bath at 55°C for 15 min , adjust the pH value of the solution to 8-9 with a saturated NaOH solution in absolute ethanol, and then add a solution of hydrazine hydrate in absolute alcohol mixed with 6 mL of hydrazine hydrate and 80 mL of absolute ethanol dropwise to the reaction solution in the round-bottomed flask , reacted in a water bath for 2h, then lowered the temperature of the water bath to 30°C and added 20mL of Pd(NO 3 ) 2 2H 2 The aqueous solution of O was reacted for half an hour, ...

Embodiment 2

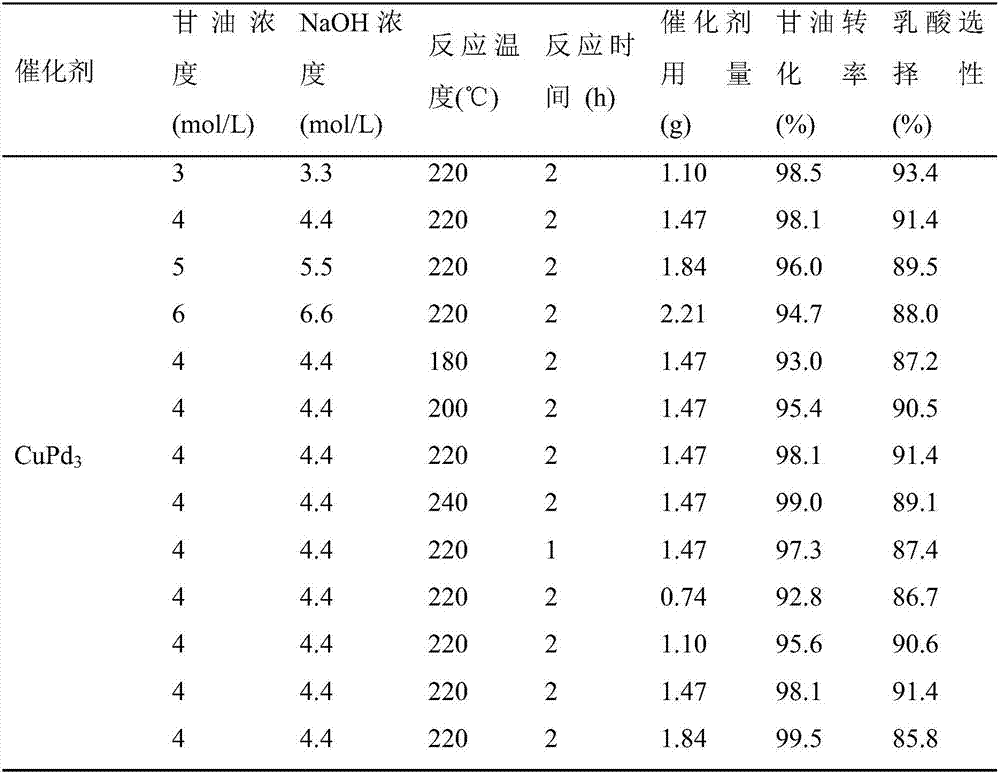

[0039] Copper palladium alloy catalyst (CuPd 3 ) preparation: preparation conditions and steps are the same as CuPd in Example 1 2 Catalyst preparation method is the same, 1.827g Cu(NO 3 ) 2 ·3H 2 O and 0.040g Pd(NO 3 ) 2 2H 2 O was changed to 1.798g Cu(NO 3 ) 2 ·3H 2 O and 0.059g Pd(NO 3 ) 2 2H 2 O.

[0040] Weigh 36.8g glycerol (Sinopharm Chemical Reagent Co., Ltd.), use a 100mL volumetric flask to make a constant volume, add it to a 300mL autoclave, then weigh 19.6g sodium hydroxide (Sinopharm Chemical Reagent Co., Ltd.) and 1.47g CuPd 3 , together into the autoclave, evacuate with high-purity nitrogen, then seal the autoclave, stir at 300rpm, heat the autoclave to 180-240°C, start timing, and react for 2 hours.

[0041] After the reaction, use a pipette to pipette 1 mL of the reaction solution and add 20 μL of isopropanol for gas chromatography analysis; also take 20 mL of the reaction solution and acidify it with hydrochloric acid until the pH is 2, calcula...

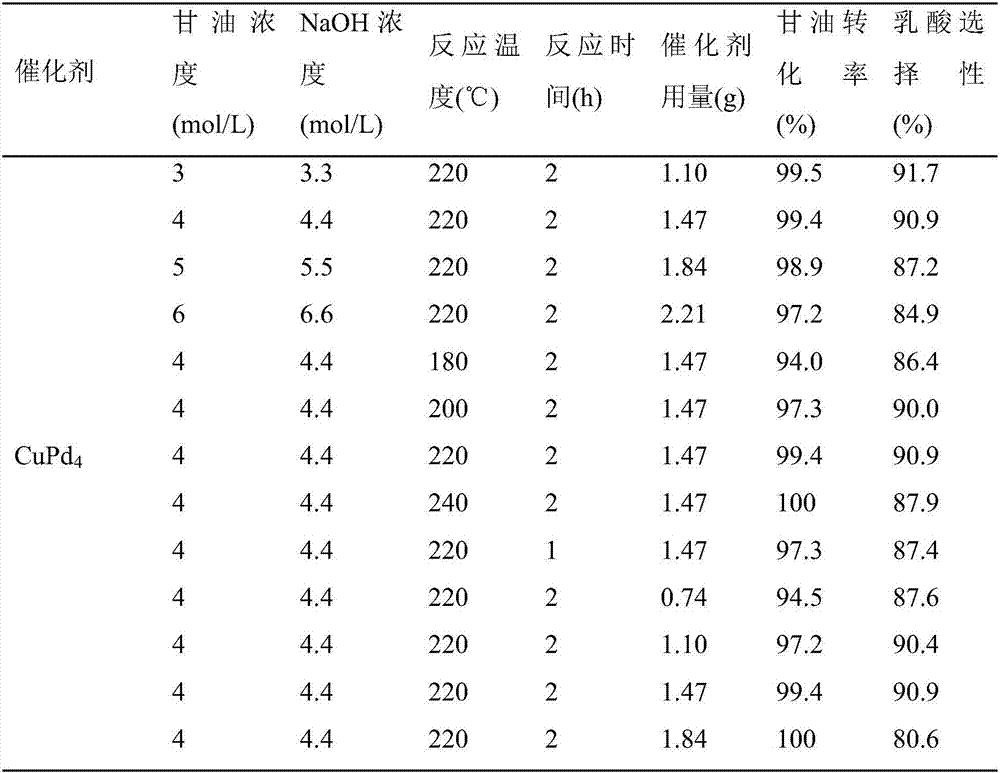

Embodiment 3

[0052] Copper palladium alloy catalyst (CuPd 4 ) preparation: preparation conditions and steps are the same as CuPd in Example 1 2 Catalyst preparation method is the same, 1.827g Cu(NO 3 ) 2 ·3H 2 O and 0.040g Pd(NO 3 ) 2 2H 2 O was changed to 1.769g Cu(NO 3 ) 2 ·3H 2 O and 0.078g Pd(NO 3 ) 2 2H 2 O.

[0053] Weigh 36.8g glycerol (Sinopharm Chemical Reagent Co., Ltd.), use a 100mL volumetric flask to make a constant volume, add it to a 300mL autoclave, then weigh 19.6g sodium hydroxide (Sinopharm Chemical Reagent Co., Ltd.) and 1.47g CuPd 4 , together into the autoclave, evacuate with high-purity nitrogen, then seal the autoclave, stir at 300rpm, heat the autoclave to 180-240°C, start timing, and react for 2 hours.

[0054] After the reaction, use a pipette to pipette 1 mL of the reaction solution and add 20 μL of isopropanol for gas chromatography analysis; also take 20 mL of the reaction solution and acidify it with hydrochloric acid until the pH is 2, calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com