Waterborne polyurethane acrylate emulsion and waterborne plastic ink prepared by same

A polyurethane acrylate and acrylate technology, applied in the chemical industry, can solve the problems of small molecular weight of the polyurethane part, affecting the water resistance of the ink, insufficient mechanical strength, etc., and achieve the effects of strong peeling force, good PP adhesion fastness, and good water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

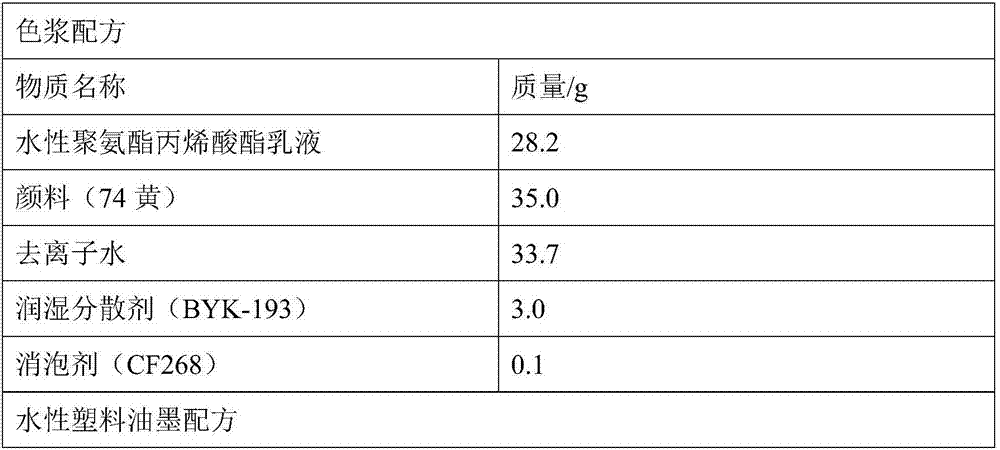

Examples

Embodiment 1

[0038] 1. Preparation of water-based polyurethane acrylate emulsion:

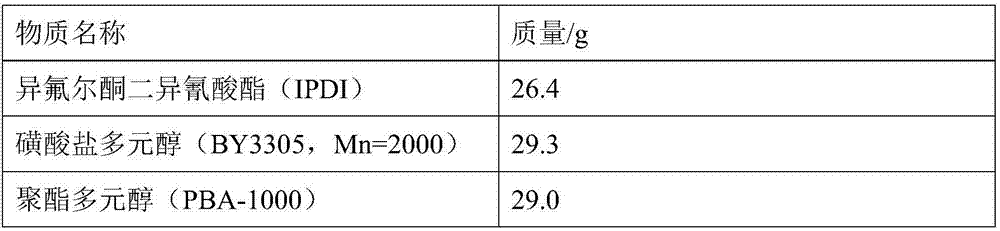

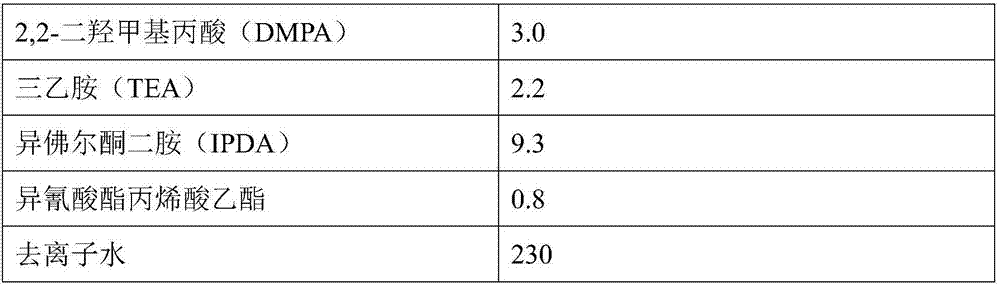

[0039] The main composition of described polyurethane pre-emulsion is as follows:

[0040]

[0041]

[0042] S1. Add IPDI to the reaction kettle, heat up to 90°C, add dehydrated BY3305, PBA-1000 and DMPA, and react until the residual -NCO reaches the theoretical value; drop to room temperature, add triethylamine, and stir well; the reaction process Use acetone to control the viscosity to avoid climbing rods; put the reaction kettle in an ice-water bath, add IPDA and deionized water and stir at high speed for 2 hours at a speed of 1200r / min; add isocyanate ethyl acrylate to continue the reaction for 1 hour;

[0043] S2. Control the temperature to 60°C, vacuumize for 1 hour to remove acetone, and obtain a polyurethane pre-emulsion;

[0044]S3. Weigh 15.0g methyl methacrylate, 4.0g butyl acrylate and 1.0g acrylic acid, and mix them uniformly for subsequent use; 0.2g ammonium persulfate is dissolved in 5...

Embodiment 2

[0053] 1. Preparation of water-based polyurethane acrylate emulsion:

[0054] The main composition of described polyurethane pre-emulsion is as follows:

[0055] Substance name

Mass / g

Hexamethylene diisocyanate (HDI)

10.9

Sulfonate polyol (BY3305, Mn=2000)

68.4

Polyether polyol (N210, Mn=1000)

17.1

2,2-Dimethylolpropionic acid (DMPA)

1.0

0.3

Isophoronediamine (IPDA)

1.5

Ethyl isocyanate acrylate

0.8

Deionized water

180

[0056] S1. Add HDI to the reaction kettle, heat up to 70°C, add dehydrated BY3305, N210, DMPA and 0.02g dibutyltin dilaurate, react until the residual -NCO reaches the theoretical value; cool down to room temperature, add sodium hydroxide , stir evenly; during the reaction process, use acetone to control the viscosity to avoid climbing rods; place the reaction kettle in an ice-water bath, add IPDA and deionized water and stir at a high spe...

Embodiment 3

[0065] 1. Preparation of water-based polyurethane acrylate emulsion:

[0066] The main composition of described polyurethane pre-emulsion is as follows:

[0067] Substance name

Mass / g

Isophorone Diisocyanate (IPDI)

19.8

Sulfonate polyol (BY3301, Mn=1500)

49.0

Polytetrahydrofuran ether glycol (PTMEG-1500)

24.3

Sodium ethylenediaminoethanesulfonate (AAS)

2.0

3.9

Ethyl isocyanate acrylate

1.0

Deionized water

200

[0068] S1. Add IPDI to the reaction kettle, raise the temperature to 90°C, add dehydrated BY3301, PTMEG-1500 and AAS, and react until the residual -NCO reaches the theoretical value; use acetone to control the viscosity during the reaction to avoid climbing rods; Place the kettle in an ice-water bath, add hexamethylenediamine and deionized water and stir at high speed for 2 hours at a speed of 1000r / min; add isocyanate ethyl acrylate and continue the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com