Ferrous carbonate/graphene composite material for negative electrode of sodium-ion battery as well as preparation method and application thereof

A sodium-ion battery and ferrous carbonate technology, applied in the field of electrochemistry, can solve the problems of cumbersome preparation methods, large volume changes, and poor specific capacity, and achieve the effects of strong operability, increased specific capacity, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

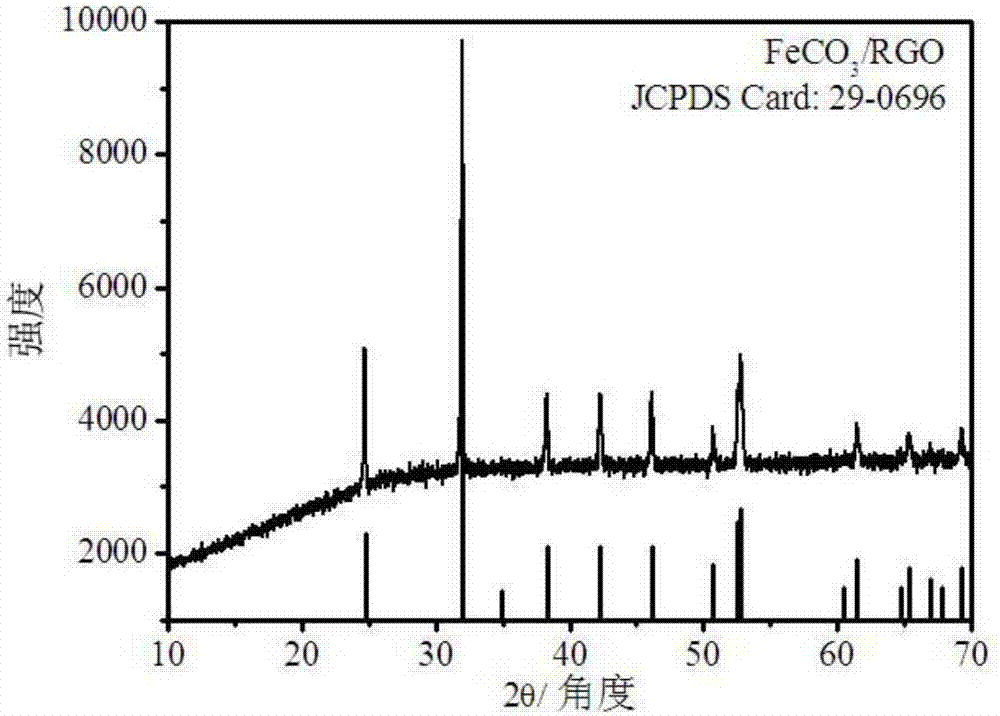

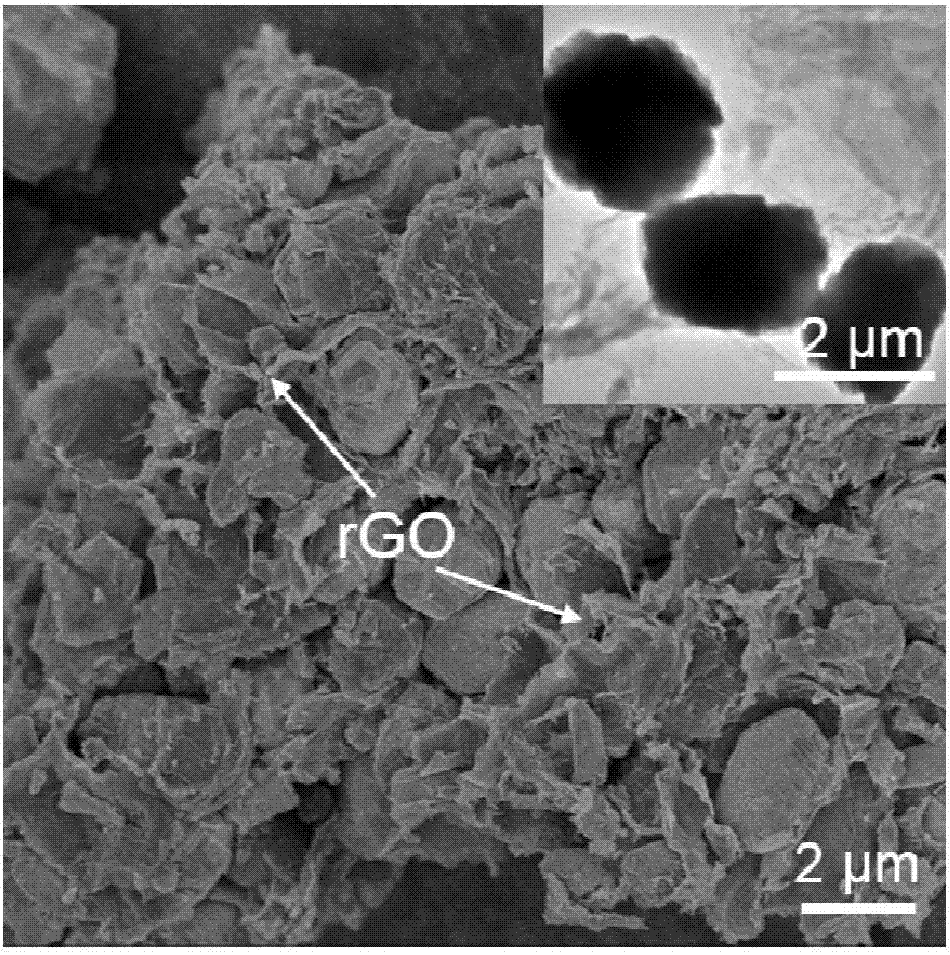

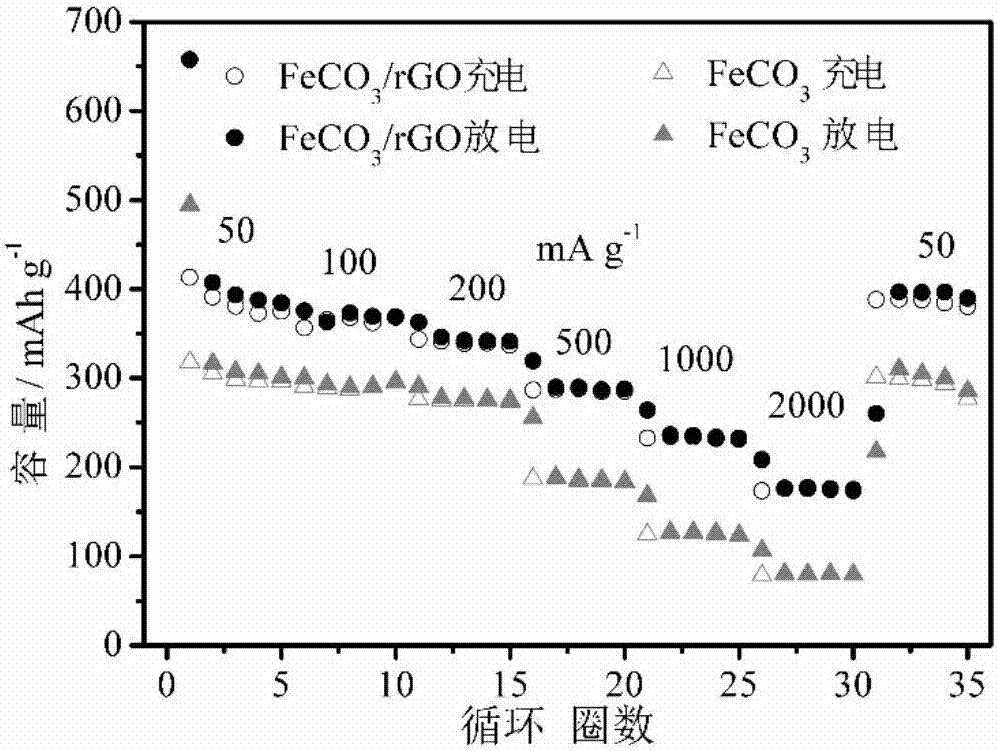

[0050] A ferrous carbonate / graphene composite material for a negative electrode of a sodium ion battery, the composite material is a composite powder material of ferrous carbonate and graphene, and the mass content of ferrous carbonate in the composite powder material is 90%;

[0051] The preparation method of ferrous carbonate / graphene composite material for above-mentioned sodium ion battery negative electrode, comprises steps as follows:

[0052] Take 6 mg of graphene oxide and ultrasonically disperse it in 35 mL of deionized water, then add 1 mmol of ferrous chloride and 0.2 g of glucose, stir at room temperature for 15 minutes, and finally quickly add 5 mL of ammonium carbonate aqueous solution (1molL -1 ) were mixed evenly, transferred to a 50mL polytetrafluoroethylene reactor, and reacted at a temperature of 160°C for 5 hours. The obtained product was washed and dried in air at 80° C. for 6 hours to obtain a ferrous carbonate / graphene composite material.

[0053] The X...

Embodiment 2

[0056] A kind of preparation method of ferrous carbonate / graphene composite material for sodium ion battery negative pole, comprises steps as follows:

[0057] Take 6 mg of graphene oxide and ultrasonically disperse it in 35 mL of deionized water, then add 2 mmol of ferrous chloride and 0.2 g of ascorbic acid, stir at room temperature for 15 minutes, and finally quickly add 5 mL of ammonium carbonate aqueous solution (1molL -1 ), mixed evenly, transferred to a 50mL polytetrafluoroethylene reactor, and reacted for 3 hours at a temperature of 180°C. The obtained product was washed and dried in air at 80° C. for 6 hours to obtain a ferrous carbonate / graphene composite material.

Embodiment 3

[0059] A kind of preparation method of ferrous carbonate / graphene composite material for sodium ion battery negative pole, comprises steps as follows:

[0060] Take 6 mg of graphene oxide and ultrasonically disperse it in 35 mL of deionized water, then add 3 mmol of ferrous chloride and 0.2 g of ascorbic acid, stir at room temperature for 15 minutes, and finally quickly add 5 mL of ammonium carbonate aqueous solution (1mol L -1 ), mixed evenly, transferred to a 50mL polytetrafluoroethylene reactor, and reacted at a temperature of 160°C for 5 hours. The obtained product was washed and dried in air at 80° C. for 6 hours to obtain a ferrous carbonate / graphene composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com