A system for recycling waste hydrochloric acid in iron-containing industries

A waste hydrochloric acid and recycling technology, applied in the oxidation water/sewage treatment, metallurgical waste water treatment, water/sewage treatment and other directions, can solve the problems of inconvenient operation, high pressure, not very suitable, etc., to reduce the purchase amount, reduce Cost, easy separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

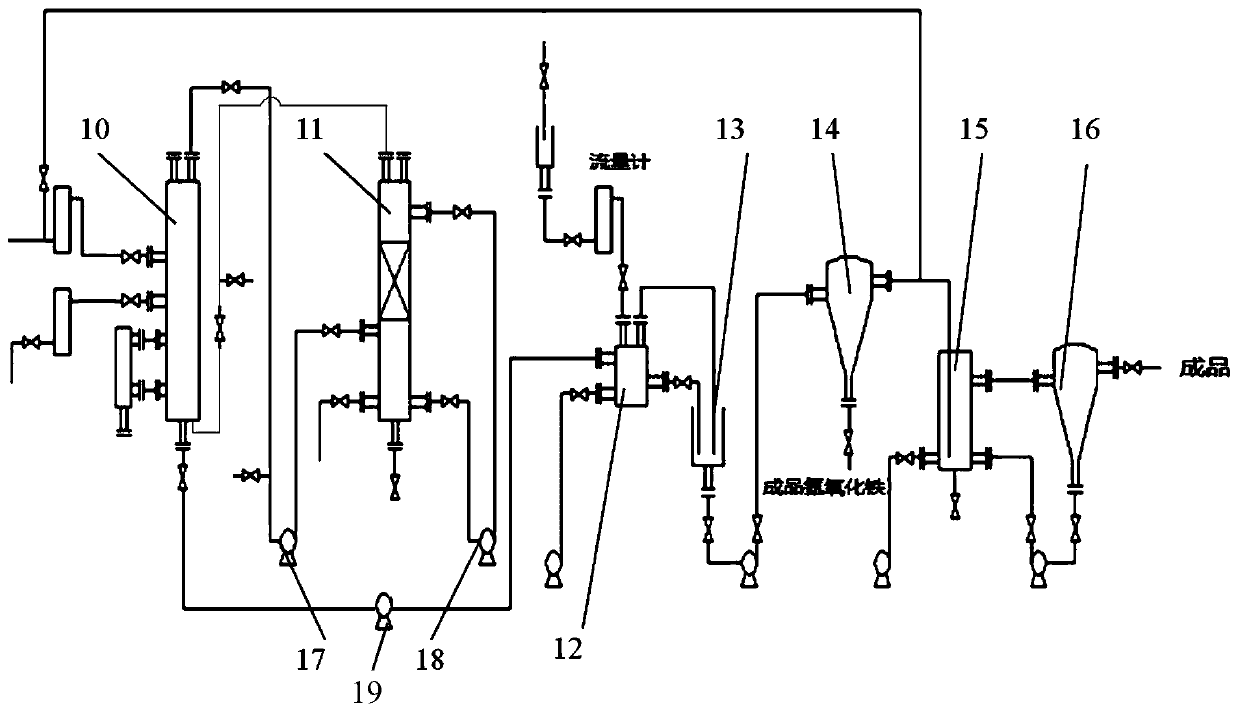

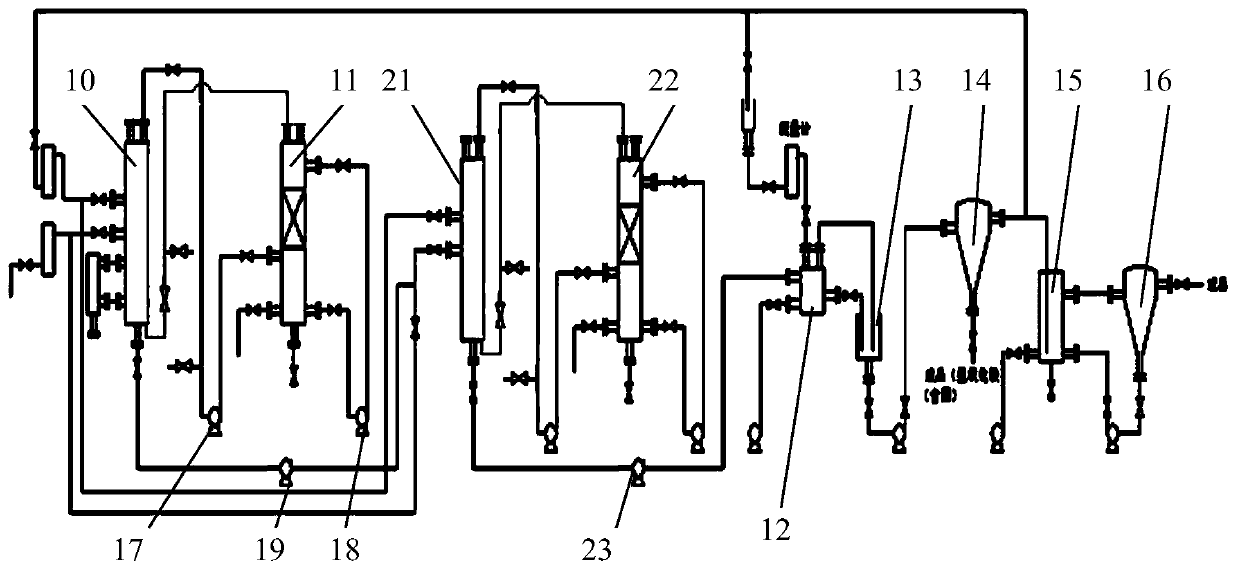

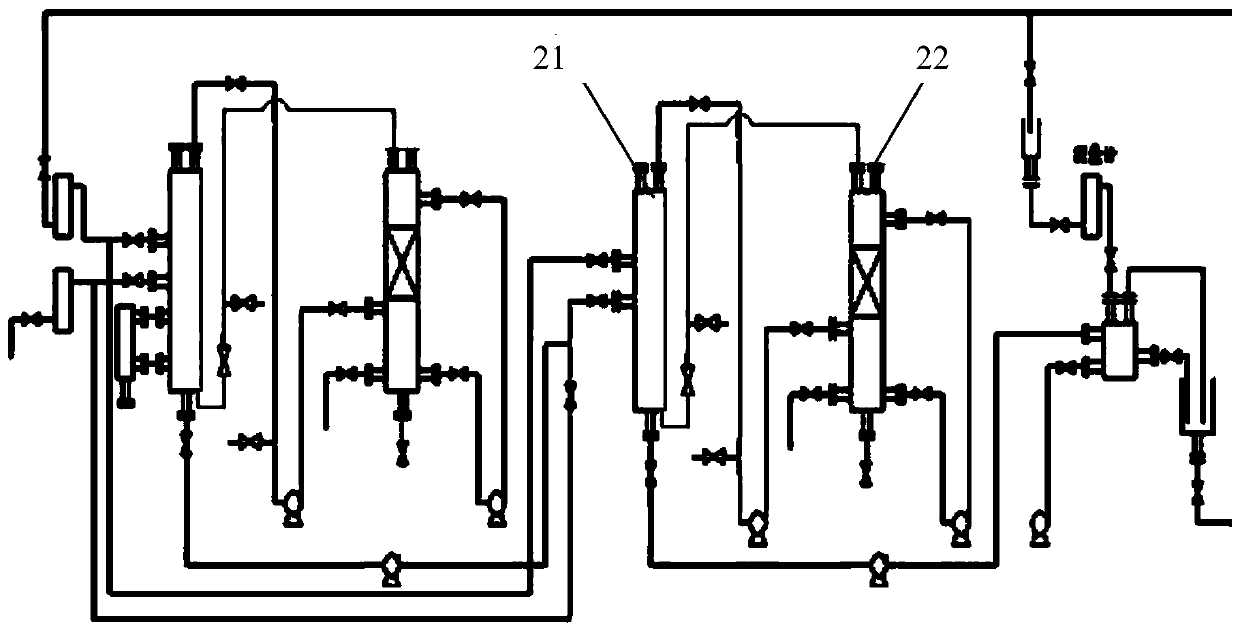

[0032]The system of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0033] figure 1 It is an embodiment of the present invention. As shown in the figure, the resource treatment system for iron-containing industrial waste hydrochloric acid includes: the first deacidification tower 10, the first pickling tower 11, the first hydrogen chloride compressor 17, the first circulating acid pump 18, and the first material pump 19. Aeration reactor 12, buffer tank 13 and solid-liquid separation device.

[0034] The first deacidification tower 10 is used to carry out bubbling and stirring, under the condition of air blowing and desorption and negative pressure, the hydrogen chloride gas produced after the salting-out agent and iron-containing industrial waste hydrochloric acid are m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com