Preparation and application of a kind of porous organic polymer

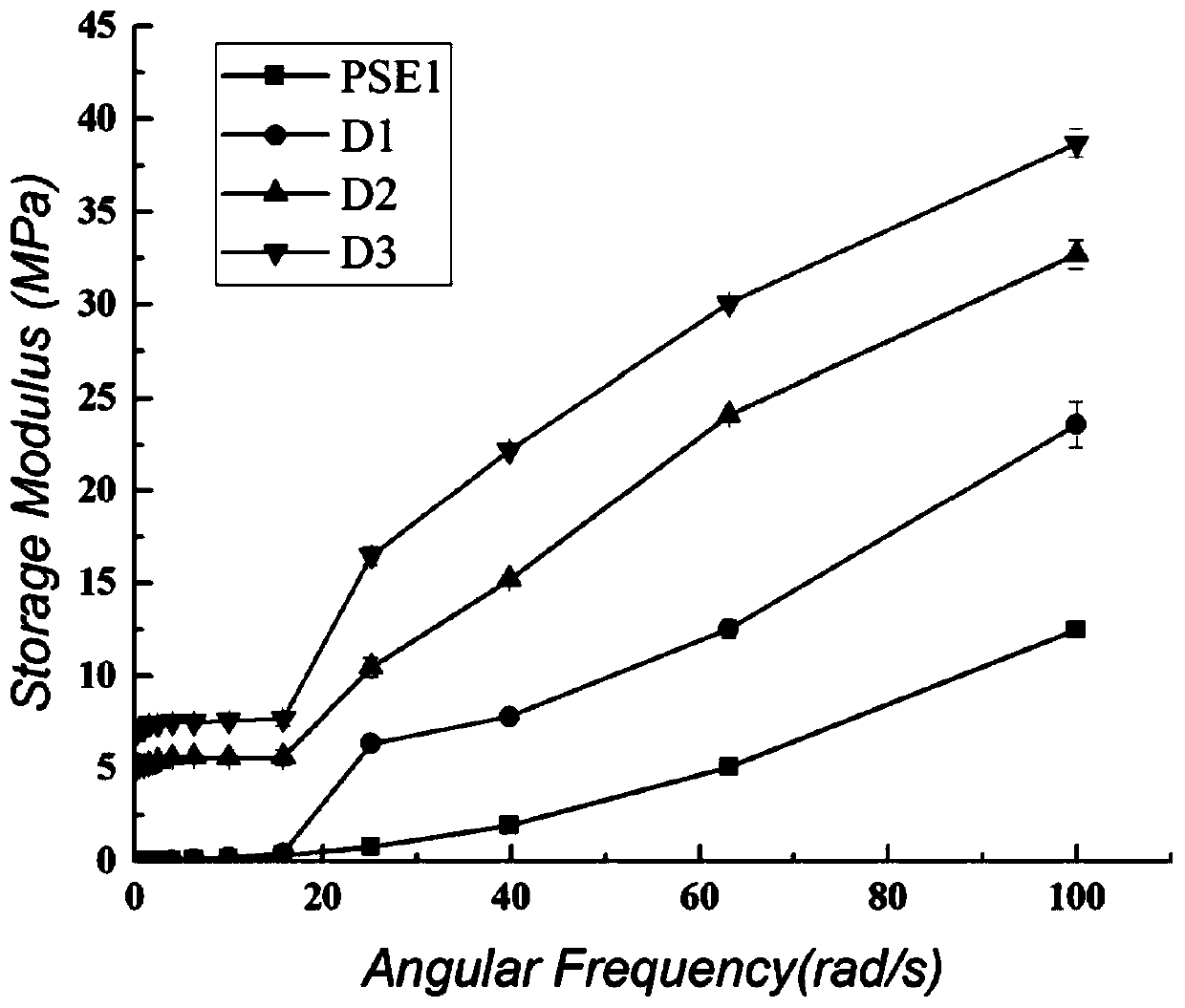

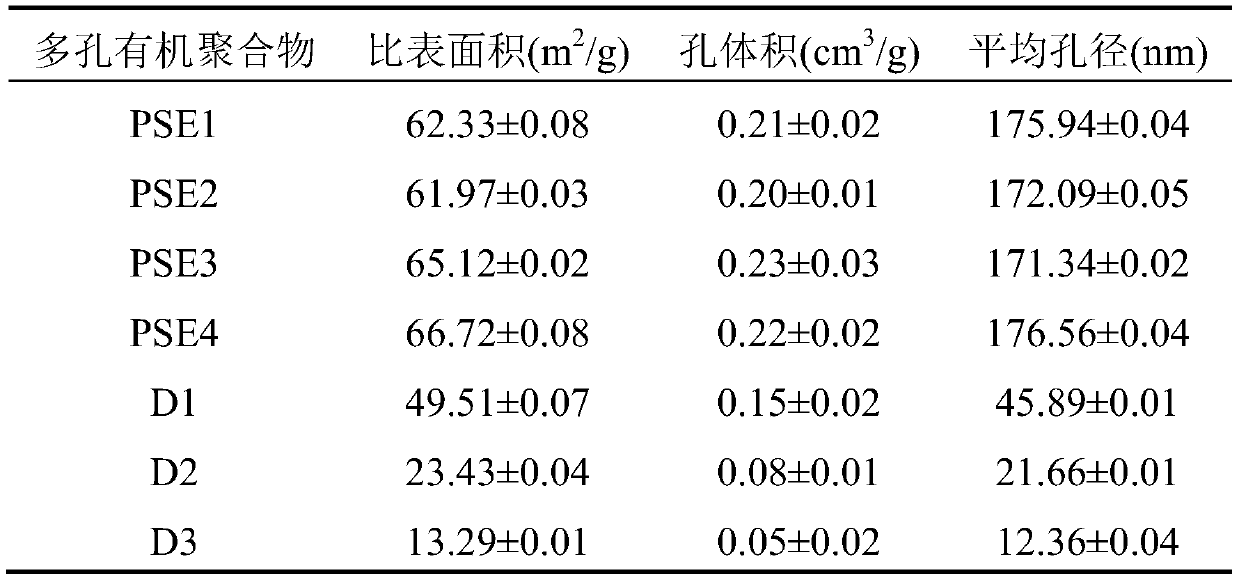

A technology of porous polymers and copolymers, applied in chemical/physical processes, ion exchange, ion exchange treatment devices, etc., can solve the problems of poor biomolecular adsorption performance, strong hydrophobicity, small pore size, etc., and achieve good hydrophilicity and adsorption performance, widening the application field, and the effect of increasing the storage modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

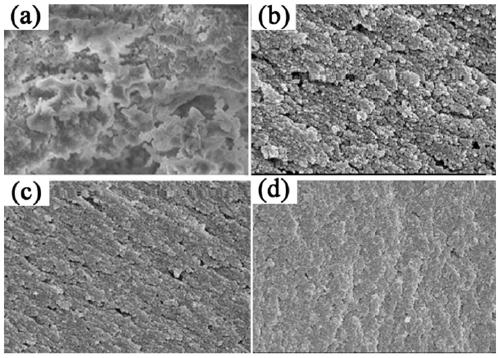

[0027] Preparation of PSE polymer: Dissolve 0.5 g of polyvinyl alcohol in 70 mL of aqueous solution at 60°C, add 0.02 g of sodium lauryl sulfate, 0.02 g of sodium carbonate, and 0.015 g of hydroquinone, and mix to obtain Continuous phase, ready for use; mix 0.2g of benzoyl peroxide, 0.1g of hexadecane, 2g of Span 80, 2.5g of styrene, and 1g of ethylene glycol dimethacrylate, mix and sonicate for 10min to obtain a dispersed phase; The continuous phase and the dispersed phase are mixed and added to the reaction vessel, under a nitrogen environment, 120 rpm continuous stirring, 65°C for 6h heating polymerization, filtered, the filtered solids are washed sequentially with water, ethanol and acetone, and then dried to obtain benzene Ethylene-ethylene glycol dimethacrylate copolymer PSE1. The adsorption capacity of PSE1 is 162mg / g (based on the dry weight of PSE1).

Embodiment 2

[0029] Preparation of PSE polymer: Dissolve 1.0 g of polyvinyl alcohol in 100 mL of aqueous solution at 100°C, add 0.03 g of sodium lauryl sulfate, 0.04 g of sodium carbonate, and 0.02 g of hydroquinone, and mix to obtain Continuous phase, ready for use; mix 0.3 g of benzoyl peroxide, 0.3 g of hexadecane, 3 g of Span 80, 4 g of styrene, and 3 g of ethylene glycol dimethacrylate, mix and sonicate for 30 minutes to obtain a dispersed phase; The continuous phase and the dispersed phase are mixed and added to the reaction vessel under an argon atmosphere, 200 rpm continuous stirring, 85°C heating and polymerization for 8 hours, filtered, the filtered solids are washed sequentially with water, methanol and acetone, and dried to obtain benzene Ethylene-ethylene glycol dimethacrylate copolymer PSE2.

[0030] Weigh 0.2 g of the prepared PSE2 resin particles, add 15 mL of 30% ethanol solution, 0.01 g of dopamine hydrochloride, and 20 mL of tris (Tris) hydrochloric acid solution, mix, adju...

Embodiment 3

[0032] Preparation of PSE polymer: Dissolve 1.5 g of polyvinyl alcohol in 200 mL of aqueous solution at 200°C, add 0.5 g of sodium lauryl sulfate, 0.6 g of sodium carbonate, and 0.4 g of hydroquinone, and mix to obtain Continuous phase, ready for use; mix 0.5 g of benzoyl peroxide, 0.4 g of hexadecane, 5 g of Span, 6 g of styrene, and 5 g of ethylene glycol dimethacrylate, mix and sonicate for 60 minutes to obtain a dispersed phase; The continuous phase and the dispersed phase are mixed and added to the reaction vessel in a carbon dioxide environment, with continuous stirring at 300 rpm, heating and polymerization at 100°C for 12 hours, and filtering. The filtered solids are washed sequentially with water, methanol and n-hexane and dried to obtain benzene Ethylene-ethylene glycol dimethacrylate copolymer PSE3.

[0033] Weigh 1g of the prepared PSE3 resin particles, add 80mL of 60% methanol solution, 40mL of tris (Tris) hydrochloric acid solution, and 0.2g of dopamine hydrochlorid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com