A method for preparing a high-throughput solvent-resistant organic/inorganic hybrid composite membrane doped with aminated graphene quantum dots

A technique of aminated graphene and hybrid compounding, which is applied in the field of membrane separation, can solve the problems of low flux, achieve large specific surface area, improve stability, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

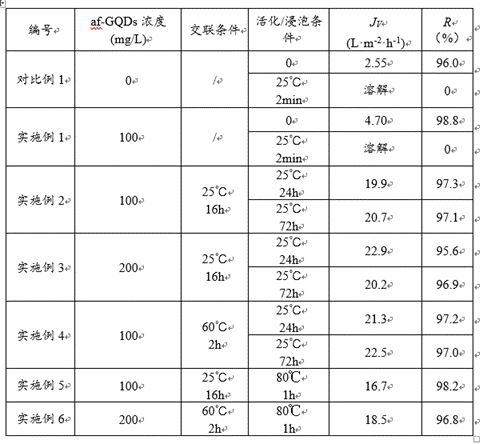

Examples

preparation example Construction

[0071] The preparation and purification steps of af-GQDs nanoparticles are as follows,

[0072] Step 1: preparation of graphene oxide;

[0073] Mix a certain amount of graphite powder, concentrated sulfuric acid and sodium nitrate evenly, stir at a temperature of 5°C for 30 minutes, then add an appropriate amount of potassium permanganate, keep the temperature below 20°C, and continue stirring for 2 hours, then the temperature of the mixture Keep at 35°C, keep stirring for 5 hours, then add an appropriate amount of deionized water, raise the temperature of the mixture to 95°C, continue stirring for 40 minutes, add a large amount of deionized water to terminate the reaction, and then add an appropriate amount of hydrogen peroxide solution, at this time The color of the mixture changed from brown-black to bright yellow;

[0074] Step 2: the purification of graphene oxide;

[0075] Add dilute hydrochloric acid to the above mixture to wash and centrifuge, retain the solid, and d...

Embodiment 1

[0091] In Example 1, the difference between the aqueous phase solution and Comparative Example 1: af-GQDs were added to the aqueous phase solution.

[0092] Dissolve the small molecule diamine compound and a certain amount of af-GQDs in deionized water, the mass concentration of the small molecule diamine compound is 2.0%, the mass concentration of af-GQDs is 0.01%, and the aqueous phase monomer solution.

[0093] The oil phase monomer solution is the same as that of Comparative Example 1.

[0094] The method of embodiment 1 is as follows:

[0095] Step 1: Pour a certain amount of af-GQDs-containing aqueous phase monomer solution on the surface of the ultrafiltration basement membrane and keep it for 30 seconds, then pour out the aqueous phase and let it dry for 30 seconds.

[0096] Step 2: Pour a certain amount of oil phase monomer solution on the surface of the ultrafiltration basement membrane that has absorbed the water phase monomer and keep it for 30s, then pour off th...

Embodiment 2

[0102] The differences from Comparative Example 1 include: the addition of af-GQDs to the aqueous phase solution, and the addition of chemical crosslinking and solvent activation steps after interfacial polymerization.

[0103] The aqueous monomer solution is the same as in Example 1.

[0104] The oil phase monomer solution is the same as that of Comparative Example 1.

[0105] Hexamethylenediamine (HDA) was dissolved in isopropanol to prepare a cross-linking agent solution with a mass concentration of 10%.

[0106] The activation solvent is N,N-dimethylformamide (DMF).

[0107] The method of embodiment 2 is as follows:

[0108] Step one to step four are identical with embodiment 1;

[0109] Step 5: Put the organic / inorganic hybrid film doped with af-GQDs obtained in step 4 into a cross-linking agent to chemically cross-link for 16 hours to obtain a cross-linked modified af-GQDs-doped organic / inorganic solvent-resistant organic / inorganic film hybrid film;

[0110] Step 6:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com