Star-like amphiphilic conjugated molecule material, and preparation method and application thereof

A conjugated molecule and amphiphilic technology, which is applied in luminescent materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., can solve the problems of complex structure of organic light-emitting diode devices and difficult processing of electron injection layer solution, and achieve effective The effect of cathode interface modification, excellent luminous brightness, and efficient blue light emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

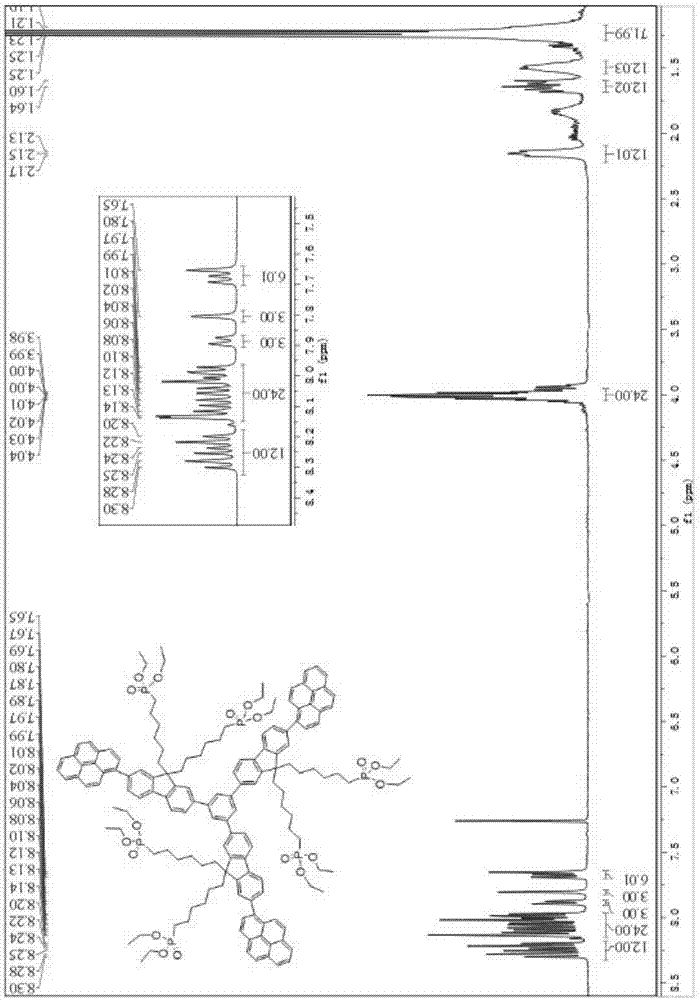

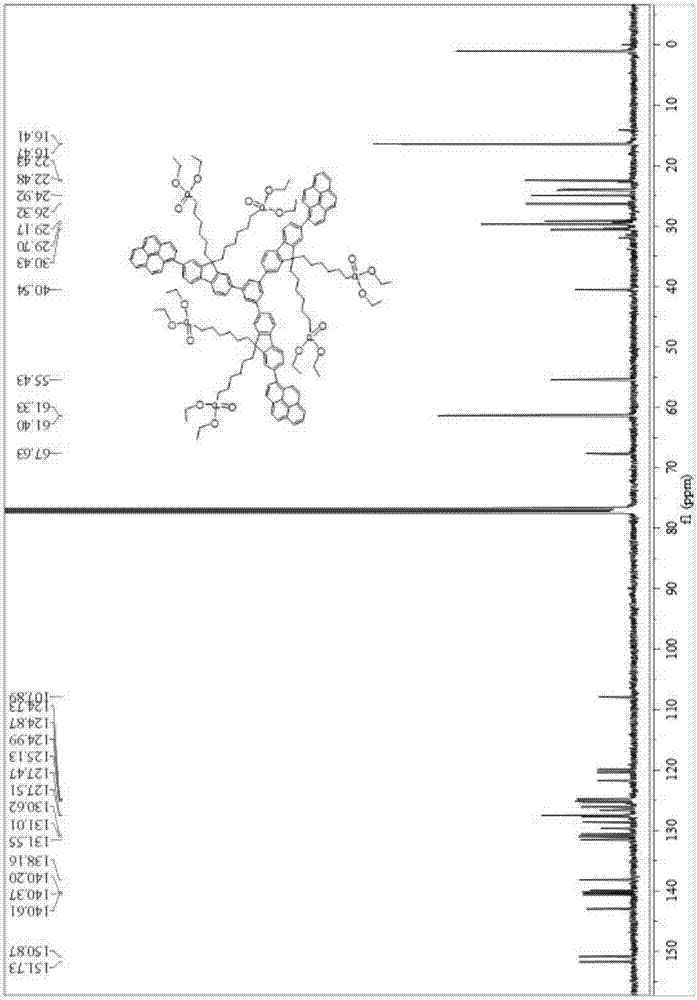

[0066] The synthetic route is as follows:

[0067]

[0068] Specific steps are as follows:

[0069] Step Ⅰ: 2,7-dibromofluorene (20g, 61.7mmol), 1,6-dibromohexane (35.5mL, 246.9mmol), tetrabutylammonium bromide (TBAB) (2g) add 50g of quality The concentration is 50% potassium hydroxide aqueous solution, react overnight at 65°C. Extracted, spin-dried, and passed through the column at 100-200 meshes to obtain 32 g of compound A with a yield of 160%.

[0070] The second step: Compound A (1g, 1.54mmol), 1-boronic acid ester pyrene (0.421g, 1.28mmol) added tetrabutylammonium bromide (TBAB) (0.099g, 0.31mmol) after pumping nitrogen three times, pumping Nitrogen, avoid light and add catalyst Pd(PPh 3 ) 4 (0.089g, 0.077mmol) was dissolved in 21mL of toluene and 7mL of potassium carbonate aqueous solution, and reacted at 95°C for 12 hours. DCM was extracted and spin-dried to pass through the column to obtain compound B with a yield of 76%.

[0071] Step III: Add compound B (0....

Embodiment 2

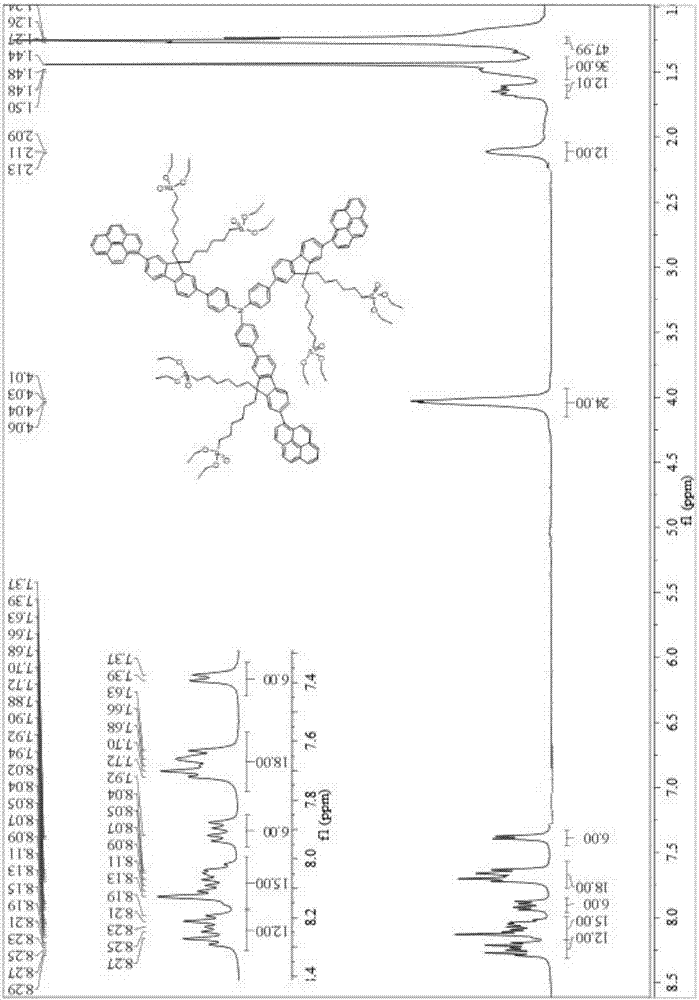

[0081] The synthetic route is:

[0082]

[0083] Specific steps are as follows:

[0084] Step Ⅰ: 2,7-dibromofluorenone (30.3g, 89.65mmol) was placed in a 500mL three-necked flask, and phenol (71mL, 591.18mmol), 20mL of methanesulfonic acid, and 120mL of CCl were added 4 , the temperature was adjusted to 80°C, and the reaction was carried out for 42h. Stop the reaction, cool with K 2 CO 3 The solution is quenched, and it should be added slowly, and a large number of bubbles will be generated. After suction filtration, the waste liquid is purple. Washed with DCM several times until the powder was about 28 g of pure white compound C, the yield was 93%.

[0085] The second step: compound C (10g, 19.67mmol), 1,6-dibromohexane (19.20g, 78.71mmol), tetrabutyl ammonium olfactory ammonium (TBAB) (2g) add 50% 50% potassium hydroxide aqueous solution , react overnight at 65°C. Extract, spin dry, and pass through the column with 100-200 mesh. 13.2 g of compound D was obtained, ...

Embodiment 3

[0097] Fabrication of organic light-emitting diodes.

[0098] OLEDs single-layer devices were prepared by spin-coating method: the device structure was ITO / PEDOT:PSS 35nm / luminescent layer 65nm / Al 80nm. Chloroform was used as a solvent, and any one of the compounds TPA-FEP / PH-FEP / TPA-OEP / PH-OEP was used for the light-emitting layer to prepare a 15 mg / mL solution. Spin coating under the protection of nitrogen, the rotating speed is 1500rpm, annealing at 80°C for 10min.

[0099] The following is a comparison of the electroluminescent performance of the above three single-layer organic light-emitting diode devices:

[0100]

[0101] a The turn-on voltage is defined as a brightness of 1cdm -2 when the working voltage. b at maximum brightness.

[0102] All four single-layer devices use star-like amphiphilic conjugated molecules as both emitter and cathode interface layers. Analyzing the device performance in the table, the current efficiency of device A based on material T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com