Culture method of rich-oil scenedesmus obliqnus

A technology of Scenedesmus obliquus and its cultivation method, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of unfavorable large-scale cultivation, collapse of the cultivation system, slow growth, etc., and achieve favorable flocculation recovery , expanding application conditions, and the effect of reasonable nutritional formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

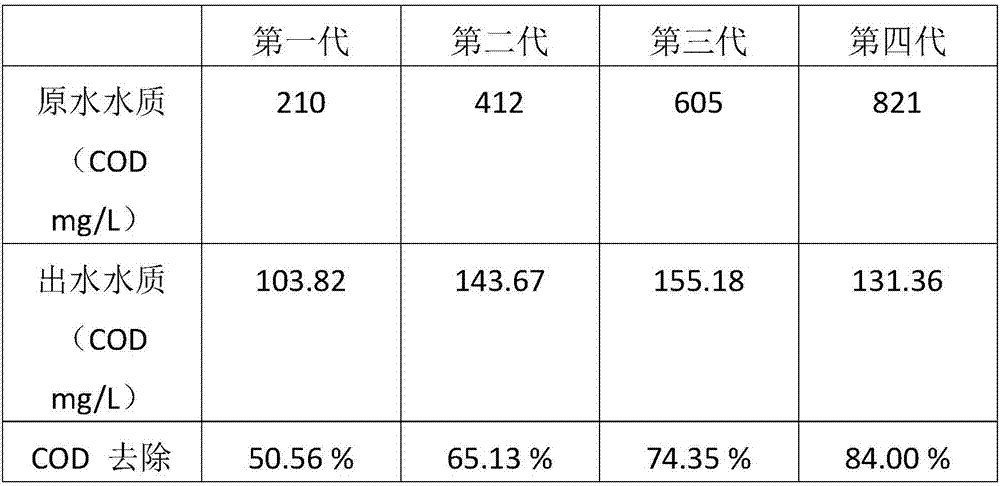

[0021] Example 1: Screening and community structure identification of Scenedesmus obliquus and mixed flora symbiotic system

[0022] The water sample extracted from the aeration tank of the wastewater treatment process of the biological flocculant production enterprise in Harbin City was packed into a sterile sampling bag and brought back to the laboratory. Microscopic observation found that there were many microorganisms and algae cells in the sample, and the corresponding microalgae and microalgae The associated flora was enriched, isolated and screened. Put the raw water samples into the simulated aeration biochemical tank reactor for continuous cultivation, place the reactor under natural light, mix with the pre-prepared simulated biological flocculant production wastewater, and aerate for a long time to keep the oxygen content at 4-5mg / L, cultured at 32°C, pH 7.5, COD maintained at around 800mg / L, TN around 90mg / L, TP around 20mg / L. The improved BG11 medium was used to s...

Embodiment 2

[0029] Example 2: Compound flora and activity verification

[0030] The composition ratio of flocculant producing bacterial community Rhizobium sp. (Rhizobium sp.), Bacillus (Bacillus sp.) and Klebsiella (Klebsiella sp.) in simulation example 1, and Scenedesmus obliquus ) for compounding. Wherein Rhizobium sp. selects specific species Rhizobium radiobacter (Rhizobium radiobacter), Bacillus sp. selects specific species as Bacillus sphaeicus, Klebsiella sp. The specific species selected is Klebsiella variicola. Among them, the single bacteria (algae) were activated with LB medium respectively, and the cell concentration was adjusted after activation, while the added concentration of Scenedesmus obliquus was two orders of magnitude higher than the concentration of the three flocculant-producing bacteria. The three flocculant-producing bacteria, namely Rhizobium ( Rhizobium sp.), Bacillus sp. and Klebsiella sp. were inoculated according to 4:4:3. All the above bacteria and alga...

Embodiment 3

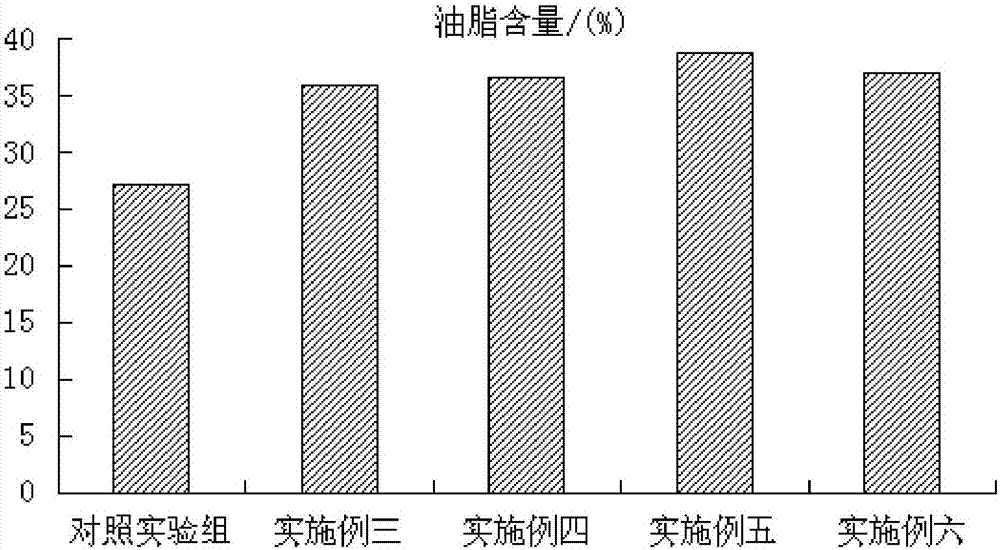

[0032] Example 3: Optimization of Growth and Oil Content of Scenedesmus obliques with Different Nutrient Concentrations and Bioflocculant Addition Concentrations

[0033] Use sterile water to configure the optimized medium of Scenedesmus obliquus with the following formula: glucose 10000mg / L, NaNO 3 150mg / L, MgSO 4 ·7H 2 O 50mg / L, K 2 HPO 4 50mg / L, MnCl 2 4H 2 O 1.00mg / L, Co(NO 3 ) 2 ·6H 2 O0.35mg / L, H 3 BO 3 8.50mg / L, EDTA 30mg / L, FeSO 4 ·7H 2 O 2.50mg / L. Additions include Rhizobium sp. Rhizobium radiobacter, Bacillus sp. Bacillus sphaeicus and Klebsiella sp. Klebsiella Bacteria (Klebsiella variicola) mixed flora fermentation liquid 10mL, wherein the inoculation ratio of the three strains is 4:4:3. The specific composition and fermentation conditions of its mixed flocculant bioflocculant fermentation liquid are as follows: glucose 10g / ml, K 2 HPO 4 5g / L, MgSO 4 ·7H 2 O 0.2g / L, urea 0.5g / L, H 2 PO 4 2g / L, NaCl 0.1g / L, yeast extract 0.5g / L, pH 7.5. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com